Introduction to Functional Testing in PCB Assembly

Functional testing is a crucial step in the PCB assembly process that ensures the proper operation and reliability of the manufactured printed circuit boards. It is a comprehensive testing method that verifies the functionality of the PCB by simulating real-world operating conditions and checking if the board performs as intended. Functional testing is performed after the PCB has undergone various manufacturing processes, such as component placement, soldering, and inspection.

In this article, we will delve into the details of functional testing in PCB assembly, exploring its importance, the different types of functional tests, the equipment used, and the benefits it offers to manufacturers and end-users alike.

The Importance of Functional Testing in PCB Assembly

Functional testing plays a vital role in the PCB assembly process for several reasons:

-

Quality Assurance: Functional testing helps identify any defects or issues in the PCB that may have been missed during earlier stages of manufacturing. By detecting these problems early, manufacturers can ensure that only high-quality, fully functional boards are delivered to customers.

-

Reliability: PCBs are used in a wide range of applications, from consumer electronics to critical systems in aerospace and medical devices. Functional testing ensures that these boards can withstand the rigors of their intended use and perform reliably over their expected lifespan.

-

Cost Savings: Identifying and rectifying issues during the functional testing stage is much more cost-effective than dealing with product failures or recalls after the boards have been shipped to customers. By catching defects early, manufacturers can save on costs associated with rework, replacements, and potential legal issues.

-

Customer Satisfaction: Delivering fully functional, reliable PCBs to customers helps build trust and loyalty, leading to repeat business and positive word-of-mouth recommendations.

Types of Functional Tests in PCB Assembly

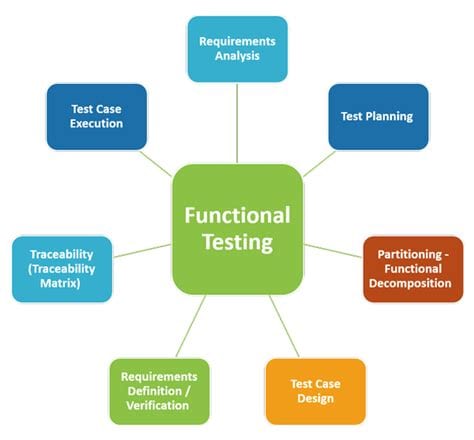

There are several types of functional tests performed during PCB assembly, each focusing on different aspects of the board’s performance. Some of the most common functional tests include:

In-Circuit Testing (ICT)

In-circuit testing is a type of functional test that verifies the presence, orientation, and functionality of individual components on the PCB. This test is performed using a specialized fixture called a “bed of nails,” which consists of an array of spring-loaded probes that make contact with specific test points on the PCB.

During the ICT process, the bed of nails fixture is lowered onto the PCB, and the probes make contact with the test points. The testing equipment then applies electrical signals to the board and measures the response at various points to ensure that each component is functioning correctly and is properly connected to the circuit.

ICT is particularly effective at identifying issues such as:

- Missing or incorrect components

- Reversed polarity of components

- Short circuits or open connections

- Incorrect component values

Boundary Scan Testing (BST)

Boundary scan testing, also known as JTAG (Joint Test Action Group) testing, is a functional test method that verifies the interconnections between digital components on a PCB. This test is performed using a special hardware interface and software that communicates with the boundary scan-enabled devices on the board.

During BST, the testing equipment sends test patterns to the boundary scan-enabled devices, which then capture the data at their input and output pins. The captured data is then compared to the expected results to identify any faults in the interconnections between the devices.

BST is particularly useful for testing complex digital circuits with high pin counts, such as microprocessors, FPGAs, and ASICs. It can detect issues such as:

- Open or short circuits between devices

- Stuck-at faults (a pin that is always at a logical high or low state)

- Incorrect pin assignments

- Timing errors

Functional Test Fixtures (FTF)

Functional test fixtures are custom-designed testing setups that simulate the real-world operating conditions of a PCB. These fixtures are used to verify the overall functionality of the board, ensuring that it performs as intended in its final application.

FTFs typically consist of a mechanical housing that holds the PCB in place, along with a set of connectors, switches, and indicators that mimic the inputs and outputs of the board in its end-use environment. The testing equipment sends signals to the board through these connectors and monitors the outputs to verify proper functionality.

Functional test fixtures are particularly useful for testing PCBs with complex interfaces, such as those with multiple connectors, displays, or user input devices. They can identify issues such as:

- Incorrect signal timing or levels

- Malfunctioning switches or indicators

- Compatibility issues with external devices

- Incorrect power supply voltages

Functional Testing Equipment

To perform functional tests on PCBs, manufacturers use a variety of specialized equipment, including:

-

Automated Test Equipment (ATE): ATEs are computer-controlled systems that can perform a wide range of functional tests on PCBs. They typically consist of a test head with multiple probes or connectors, a test fixture to hold the PCB, and software to control the testing process and analyze the results.

-

Oscilloscopes: Oscilloscopes are used to visualize and measure electrical signals on a PCB during functional testing. They display the voltage, frequency, and timing of signals, allowing engineers to identify any anomalies or deviations from the expected behavior.

-

Multimeters: Multimeters are used to measure various electrical properties, such as voltage, current, and resistance, at specific points on the PCB. They are particularly useful for verifying the correct operation of analog components and power supply circuits.

-

Logic Analyzers: Logic analyzers are used to capture and display digital signals on a PCB. They can monitor multiple signals simultaneously, making them ideal for debugging complex digital circuits and identifying timing issues.

-

Thermal Imaging Cameras: Thermal imaging cameras are used to detect hot spots or temperature anomalies on a PCB during functional testing. They can help identify issues such as overheating components, insufficient cooling, or power dissipation problems.

Benefits of Functional Testing in PCB Assembly

Implementing a comprehensive functional testing process in PCB assembly offers several benefits to manufacturers and end-users:

-

Improved Product Quality: By identifying and addressing issues during functional testing, manufacturers can ensure that the final products meet or exceed the required quality standards. This leads to fewer field failures, returns, and customer complaints.

-

Reduced Manufacturing Costs: Functional testing helps catch defects early in the manufacturing process, reducing the need for costly rework or scrap. This ultimately leads to lower production costs and improved profitability.

-

Faster Time-to-Market: By streamlining the testing process and identifying issues quickly, functional testing enables manufacturers to bring products to market faster. This is particularly important in industries with short product life cycles or rapid innovation.

-

Enhanced Reliability and Durability: Functional testing ensures that PCBs can withstand the stresses and environmental conditions they will face in their end-use applications. This leads to more reliable and durable products, which can improve customer satisfaction and brand reputation.

-

Compliance with Industry Standards: Many industries have specific standards and regulations that PCBs must meet, such as those related to safety, electromagnetic compatibility, or environmental sustainability. Functional testing helps manufacturers ensure compliance with these standards, avoiding potential legal issues or penalties.

Challenges and Best Practices in Functional Testing

While functional testing is essential for ensuring the quality and reliability of PCBs, it also presents some challenges that manufacturers must address:

-

Test Coverage: Ensuring adequate test coverage can be challenging, particularly for complex PCBs with a large number of components and interconnections. Manufacturers must strike a balance between thorough testing and reasonable test times and costs.

-

Test Fixture Design: Designing and building functional test fixtures can be time-consuming and expensive, especially for PCBs with unique form factors or interfaces. Manufacturers must invest in the development of reliable, reusable test fixtures to minimize these costs over time.

-

Skilled Personnel: Functional testing requires skilled personnel who understand the intricacies of PCB design, manufacturing, and testing. Manufacturers must invest in training and retaining qualified technicians and engineers to ensure consistent and accurate test results.

To overcome these challenges and ensure effective functional testing, manufacturers should follow some best practices:

-

Design for Testability: PCB Designers should incorporate testability features into their designs, such as test points, boundary scan chains, or built-in self-test (BIST) capabilities. This can simplify the testing process and improve test coverage.

-

Standardize Test Procedures: Manufacturers should establish standardized test procedures and protocols to ensure consistency and repeatability across different products and test stations. This can help reduce errors and improve efficiency.

-

Invest in Automation: Automated test equipment and software can significantly reduce test times and improve accuracy compared to manual testing methods. Manufacturers should invest in automation technologies to streamline their functional testing processes.

-

Collaborate with Suppliers: Manufacturers should work closely with their component suppliers to ensure that the parts used in their PCBs are of high quality and meet the required specifications. This can help reduce the likelihood of component-related issues during functional testing.

-

Continuously Monitor and Improve: Manufacturers should continuously monitor their functional testing processes and analyze the results to identify areas for improvement. This may involve updating test procedures, investing in new equipment, or providing additional training to personnel.

Frequently Asked Questions (FAQ)

- What is the difference between functional testing and other types of PCB Testing, such as in-circuit testing or flying probe testing?

Functional testing focuses on verifying the overall performance and functionality of the PCB in its intended application, while in-circuit testing and flying probe testing are primarily used to identify manufacturing defects and component-level issues. Functional testing typically involves simulating real-world operating conditions and checking the board’s response, while in-circuit and flying probe tests are more focused on the electrical properties and connections of individual components.

- Is functional testing always necessary for PCBs?

While functional testing is highly recommended for most PCBs, the extent and complexity of the testing process may vary depending on the application and the criticality of the board. For example, PCBs used in life-critical systems, such as medical devices or aerospace equipment, may require more rigorous functional testing than those used in consumer electronics. However, even for less critical applications, functional testing can help ensure product quality, reliability, and customer satisfaction.

- How long does functional testing take in PCB assembly?

The duration of functional testing can vary widely depending on the complexity of the PCB, the number of components, and the types of tests performed. Simple boards with few components may take only a few minutes to test, while complex boards with hundreds of components and multiple connectors may require several hours or even days of testing. Manufacturers must balance the need for thorough testing with the desire to minimize production times and costs.

- Can functional testing be performed on prototype PCBs?

Yes, functional testing can and should be performed on prototype PCBs to identify any design or performance issues early in the development process. Testing prototypes can help validate the design, verify the functionality of critical components, and identify any areas for improvement before committing to full-scale production. However, the testing process for prototypes may be less automated and more focused on specific aspects of the design compared to the testing of production boards.

- How can manufacturers ensure the accuracy and reliability of functional test results?

To ensure the accuracy and reliability of functional test results, manufacturers should follow several best practices, such as:

- Regularly calibrating and maintaining test equipment

- Using high-quality, reliable test fixtures and connectors

- Establishing standardized test procedures and protocols

- Providing adequate training and supervision for testing personnel

- Implementing statistical process control (SPC) techniques to monitor test results and identify any trends or anomalies

- Conducting periodic audits and reviews of the testing process to identify areas for improvement

By adhering to these best practices, manufacturers can minimize the risk of false positives, false negatives, or inconsistent test results, ensuring that their functional testing process is effective and reliable.

Conclusion

Functional testing is a critical step in the PCB assembly process, ensuring that the manufactured boards perform as intended in their end-use applications. By simulating real-world operating conditions and verifying the overall functionality of the PCB, functional testing helps identify any design, manufacturing, or component-related issues that could impact the quality, reliability, or durability of the final product.

Manufacturers must invest in the appropriate equipment, personnel, and processes to implement effective functional testing, balancing the need for thorough testing with the desire to minimize production times and costs. By following best practices such as designing for testability, standardizing test procedures, investing in automation, collaborating with suppliers, and continuously monitoring and improving the testing process, manufacturers can overcome the challenges associated with functional testing and deliver high-quality, reliable PCBs to their customers.

As PCB technology continues to evolve and the demands for performance, reliability, and functionality increase, the importance of functional testing in PCB assembly will only continue to grow. By embracing this critical step in the manufacturing process, PCB assembly providers can differentiate themselves in the market, build strong relationships with their customers, and contribute to the advancement of electronics technology across a wide range of industries.

No responses yet