What is BGA Soldering?

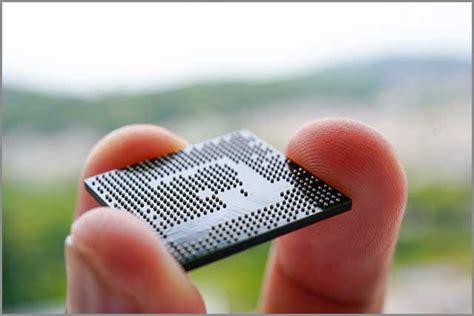

BGA (Ball Grid Array) soldering is a process used to attach BGA components to printed circuit boards (PCBs). BGA components have a grid of solder balls on the bottom surface, which are used to make electrical connections to the PCB. BGA soldering involves heating the solder balls until they melt and form a permanent connection between the component and the PCB.

Advantages of BGA Soldering

BGA soldering offers several advantages over other types of component packaging and soldering methods:

- High density: BGA components can have hundreds or even thousands of solder balls, allowing for a high density of connections in a small area.

- Improved electrical performance: The short connections between the BGA component and the PCB reduce inductance and improve signal integrity.

- Better thermal performance: The large number of solder balls provides a good thermal path for heat dissipation.

- Reduced package size: BGA components can be smaller than other types of packages with the same number of connections.

Challenges of BGA Soldering

Despite its advantages, BGA soldering also presents some challenges:

- Alignment: Proper alignment between the BGA component and the PCB is critical for a successful soldering process.

- Inspection: After soldering, it can be difficult to visually inspect the solder joints under the BGA component.

- Rework: If a BGA component needs to be removed or replaced, the process can be complex and time-consuming.

- Thermal management: Proper thermal management is necessary to prevent damage to the BGA component or the PCB during the soldering process.

The BGA Soldering Process

Step 1: PCB Preparation

Before soldering the BGA component, the PCB must be properly prepared:

- Solder paste application: Solder paste is applied to the PCB pads using a stencil or screen printing process. The solder paste consists of tiny solder spheres suspended in a flux matrix.

- Placement of other components: Any other components that need to be soldered to the PCB should be placed before the BGA component.

Step 2: BGA Component Placement

The BGA component is placed onto the PCB using a pick-and-place machine or by hand using a placement tool. Proper alignment is critical at this stage.

Step 3: Reflow Soldering

The PCB with the BGA component is then placed in a reflow oven. The reflow process involves heating the PCB and the component to a specific temperature profile, which melts the solder paste and forms a permanent connection between the component and the PCB.

A typical reflow temperature profile consists of four stages:

- Preheat: The PCB and components are gradually heated to a temperature below the melting point of the solder.

- Thermal soak: The temperature is maintained for a specific time to ensure even heating of the PCB and components.

- Reflow: The temperature is increased above the melting point of the solder, causing the solder to melt and form a connection between the component and the PCB.

- Cooling: The PCB and components are cooled gradually to room temperature, allowing the solder to solidify.

| Stage | Temperature Range | Time |

|---|---|---|

| Preheat | 150°C – 180°C | 60-90 seconds |

| Thermal Soak | 180°C – 200°C | 60-120 seconds |

| Reflow | 220°C – 250°C | 30-90 seconds |

| Cooling | 250°C – Room Temp | 60-120 seconds |

Table 1: Typical BGA reflow temperature profile

Step 4: Inspection

After the reflow process, the solder joints should be inspected to ensure proper connection between the BGA component and the PCB. This can be done using X-ray imaging, as the solder joints are hidden under the component.

Step 5: Rework (if necessary)

If any issues are found during the inspection process, the BGA component may need to be removed and resoldered. This process involves heating the component to melt the solder, removing the component, and then cleaning the PCB pads before repeating the soldering process.

BGA Soldering Equipment

To perform BGA soldering, several pieces of equipment are necessary:

- Stencil printer: Used to apply solder paste to the PCB pads.

- Pick-and-place machine: Used to place the BGA component onto the PCB with proper alignment.

- Reflow oven: Used to heat the PCB and components to the proper temperature profile for soldering.

- X-ray inspection system: Used to inspect the solder joints under the BGA component after soldering.

- Rework station: Used to remove and resolder BGA components if necessary.

BGA Soldering Materials

The main materials used in BGA soldering are:

- Solder paste: A mixture of tiny solder spheres and flux, used to form the connection between the BGA component and the PCB.

- Flux: A chemical agent that helps to remove oxides from the metal surfaces and promote wetting of the solder.

- Solder balls: The small solder spheres that are part of the BGA component package.

Frequently Asked Questions (FAQ)

1. What is the difference between BGA and SMD soldering?

SMD (Surface Mount Device) soldering refers to the process of soldering any component that mounts onto the surface of a PCB, including BGA components. BGA soldering is a specific type of SMD soldering that involves attaching BGA components to a PCB.

2. Can BGA components be soldered by hand?

While it is possible to solder BGA components by hand, it is not recommended due to the high precision and temperature control required. Hand soldering BGA components can lead to poor alignment, incomplete solder joints, and damage to the component or PCB.

3. How do you inspect BGA solder joints?

BGA solder joints are usually inspected using X-ray imaging, as the solder joints are hidden under the component. X-ray inspection allows for the detection of voids, shorts, and other defects in the solder joints.

4. What causes BGA soldering defects?

BGA soldering defects can be caused by various factors, including:

- Poor alignment of the component on the PCB

- Incorrect solder paste application

- Improper reflow temperature profile

- Contamination of the PCB or component surfaces

- Mechanical stress on the solder joints

5. How can I prevent BGA soldering defects?

To prevent BGA soldering defects, follow these guidelines:

- Ensure proper alignment of the BGA component on the PCB

- Use a stencil or screen printing process for precise solder paste application

- Follow the recommended reflow temperature profile for the specific solder paste and component

- Keep the PCB and component surfaces clean and free of contamination

- Use proper handling and storage procedures to avoid mechanical stress on the solder joints

Conclusion

BGA soldering is a complex process that requires specialized equipment, materials, and expertise. By understanding the basics of BGA soldering, including the process steps, equipment, materials, and potential challenges, you can ensure successful and reliable attachment of BGA components to PCBs. Proper process control and inspection are critical to achieving high-quality BGA solder joints and preventing defects that can lead to product failures.

No responses yet