What is Heat Shrink Tubing?

Heat shrink tubing is a flexible, pre-stretched plastic tube that shrinks when exposed to heat. It is designed to fit snugly around wires, cables, and other objects, providing a tight, protective seal. The tubing is made from various materials, including polyolefin, PVC, and fluoropolymers, each with unique properties and temperature ratings.

Advantages of Heat Shrink Tubing

Heat shrink tubing offers several benefits, making it a popular choice across industries:

- Insulation: Heat shrink tubing provides electrical insulation, protecting components from short circuits and electrical leakage.

- Protection: The tight seal created by heat shrink tubing protects wires and cables from abrasion, chemicals, and environmental factors.

- Strain relief: Heat shrink tubing reduces stress on wires and cables at termination points, preventing damage and increasing longevity.

- Organization: Color-coded heat shrink tubing helps in identifying and organizing wires and cables.

- Aesthetics: Heat shrink tubing provides a clean, professional look to electrical installations.

Heat Shrink Tubing Temperature Ratings

Heat shrink tubing is available in various temperature ratings, each suitable for specific applications. The temperature rating indicates the maximum continuous operating temperature the tubing can withstand without degradation.

Common Heat Shrink Tubing Temperature Ratings

| Temperature Rating | Material | Typical Applications |

|---|---|---|

| 105°C (221°F) | Polyolefin | General purpose, low-temperature environments |

| 125°C (257°F) | Polyolefin, PVC | Automotive, marine, industrial |

| 135°C (275°F) | Cross-linked Polyolefin | High-temperature environments, automotive, aerospace |

| 200°C (392°F) | Fluoropolymer (PTFE, FEP) | High-temperature, chemical-resistant applications |

It is essential to select heat shrink tubing with a temperature rating suitable for your application. Using tubing with a lower temperature rating than required can lead to premature failure and compromise the protection of your components.

Shrink Temperature vs. Operating Temperature

When working with heat shrink tubing, it is important to distinguish between the shrink temperature and the continuous operating temperature.

- Shrink temperature: The temperature at which the tubing begins to shrink and conforms to the object it is applied to. This temperature is typically higher than the continuous operating temperature.

- Continuous operating temperature: The maximum temperature at which the heat shrink tubing can maintain its properties and performance over an extended period.

Refer to the manufacturer’s specifications for the exact shrink temperature and continuous operating temperature of the heat shrink tubing you are using.

Selecting the Right Heat Shrink Tubing

To ensure optimal performance and reliability, consider the following factors when selecting heat shrink tubing:

- Temperature rating: Choose a tubing with a temperature rating suitable for your application’s environment and operating conditions.

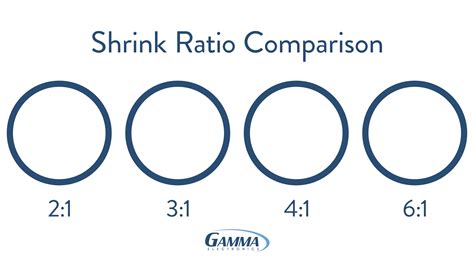

- Shrink ratio: Heat shrink tubing is available in various shrink ratios, typically ranging from 2:1 to 6:1. A higher shrink ratio allows the tubing to fit over larger objects and creates a tighter seal.

- Material: Consider the material properties, such as chemical resistance, flexibility, and dielectric strength, based on your application requirements.

- Size: Select the appropriate tubing size based on the diameter of the object you want to cover. Refer to the manufacturer’s size charts and recommendations.

- Color: Heat shrink tubing is available in various colors, which can be used for color-coding, identification, and organization purposes.

Heat Shrink Tubing Application Process

To apply heat shrink tubing correctly, follow these steps:

- Clean the surface: Ensure the object you want to cover is clean, dry, and free from debris or contaminants.

- Cut the tubing: Cut the heat shrink tubing to the desired length, allowing for a slight overlap on both ends.

- Slide the tubing: Slide the tubing over the object, ensuring it is positioned correctly.

- Apply heat: Use a heat gun, torch, or other suitable heating device to apply heat evenly around the tubing. Start from the center and work your way towards the ends. Be cautious not to overheat the tubing, as it may cause damage or char the material.

- Allow cooling: Once the tubing has shrunk and conformed to the object, allow it to cool completely before handling or applying any stress.

Heat-Shrink Recommendations

Here are some recommendations to help you choose the right heat shrink tubing for your needs:

- For general-purpose applications in low-temperature environments, use polyolefin tubing with a 105°C (221°F) temperature rating.

- In automotive, marine, and industrial settings, opt for polyolefin or PVC tubing with a 125°C (257°F) temperature rating.

- For high-temperature environments and applications in the automotive and aerospace industries, choose cross-linked polyolefin tubing with a 135°C (275°F) temperature rating.

- When chemical resistance and high-temperature performance are critical, such as in harsh industrial environments, select fluoropolymer (PTFE or FEP) tubing with a 200°C (392°F) temperature rating.

- Always refer to the manufacturer’s specifications and guidelines for the specific heat shrink tubing you are using to ensure proper application and performance.

Frequently Asked Questions (FAQ)

-

Q: Can I use a hair dryer to shrink heat shrink tubing?

A: While a hair dryer may provide enough heat to shrink some types of tubing, it is not recommended. Hair dryers may not reach the required temperature and can lead to uneven shrinking. It is best to use a dedicated heat gun or torch designed for heat shrink tubing applications. -

Q: Is it necessary to use adhesive-lined heat shrink tubing?

A: Adhesive-lined heat shrink tubing provides an additional layer of protection and creates a watertight seal. It is useful in applications where moisture resistance is crucial, such as in marine or outdoor environments. However, for general-purpose applications, non-adhesive tubing is sufficient. -

Q: Can I reuse heat shrink tubing?

A: No, heat shrink tubing is a single-use product. Once it has been shrunk, it cannot be resized or reused. If you need to remove the tubing, you must cut it off and apply new tubing. -

Q: How do I determine the proper size of heat shrink tubing for my application?

A: To determine the right size, measure the diameter of the object you want to cover and refer to the manufacturer’s size chart. The tubing should have a slightly larger diameter than the object to allow for easy installation before shrinking. -

Q: Can heat shrink tubing be used for high-voltage applications?

A: Yes, specialized heat shrink tubing is available for high-voltage applications. These tubings have higher dielectric strength and are designed to withstand the stresses associated with high-voltage environments. Always consult with the manufacturer and follow their recommendations for high-voltage applications.

Conclusion

Heat shrink tubing is an indispensable component in various industries, providing insulation, protection, and strain relief for wires, cables, and other components. Understanding the appropriate temperature ratings and selecting the right tubing for your application is crucial to ensure optimal performance and longevity.

By considering factors such as temperature rating, shrink ratio, material, size, and color, you can choose the best heat shrink tubing for your specific needs. Always refer to the manufacturer’s specifications and guidelines for proper application and maximum performance.

With this comprehensive guide and the heat-shrink recommendations provided, you are well-equipped to make informed decisions when working with heat shrink tubing in your projects and applications.

No responses yet