What is Agile Prototyping?

Agile prototyping is an iterative approach to developing products, especially hardware, that emphasizes rapid cycles of designing, building, and testing prototypes to gather feedback and make improvements. The agile prototyping process allows teams to quickly validate ideas, learn about user needs, and evolve the product design in an efficient and flexible manner.

Key characteristics of agile prototyping include:

- Short, timeboxed iterations (typically 1-4 weeks)

- Focus on delivering working prototypes

- Close collaboration between cross-functional team members

- Emphasis on user feedback and data to guide decisions

- Willingness to embrace change and adapt plans

Agile prototyping has its roots in agile software development methodologies like Scrum and Extreme Programming (XP). However, it has been adapted for the unique challenges of hardware development, which often involves longer lead times, physical constraints, and higher costs compared to software.

Why Use Agile Prototyping for Hardware Development?

Traditionally, hardware development followed a linear, waterfall-style process with lengthy upfront design phases followed by a “big bang” integration and testing phase. This approach often led to products that didn’t meet user needs, ran over budget, and were late to market.

Agile prototyping offers several benefits for hardware development teams:

-

Reduced risk: By validating ideas early and often with real users, teams can identify and address issues before investing significant time and resources. This helps avoid costly mistakes and rework later in the development process.

-

Faster time-to-market: The iterative nature of agile prototyping allows teams to incrementally deliver value and get products to market faster. Instead of waiting for a “perfect” design, teams can release early versions and continue to improve based on user feedback.

-

Increased innovation: Agile prototyping creates a culture of experimentation and learning. Teams are encouraged to try new ideas, learn from failures, and continuously push the boundaries of what’s possible. This mindset leads to more innovative solutions.

-

Better user outcomes: By involving users throughout the development process, teams can ensure they are building products that solve real problems and meet user needs. Regular user testing and feedback helps keep the team aligned with customer requirements.

-

Improved team collaboration: Agile prototyping brings together cross-functional teams (e.g. engineering, design, marketing, manufacturing) to work closely together. This breaks down silos, improves communication, and helps the team make better decisions.

The Agile Prototyping Process

While each team’s specific approach may vary, a typical agile hardware prototyping process follows these high-level steps:

-

Concept generation: The team brainstorms ideas and defines the product vision and high-level requirements. This may involve user research, market analysis, and technical feasibility studies.

-

Prototype planning: Based on the product vision, the team plans the first prototype iteration. They prioritize features, define success criteria, and establish a timeline and budget.

-

Prototype design: The team creates detailed designs for the prototype, including electronics, mechanical enclosures, and firmware. They may use computer-aided design (CAD) tools, breadboarding, and rapid prototyping techniques like 3D printing.

-

Prototype building: Engineers and technicians assemble the physical prototype using off-the-shelf components, custom PCBs, and machined or printed parts. They also develop firmware and test individual subsystems.

-

Prototype testing: The team conducts thorough testing of the integrated prototype to verify functionality, reliability, and performance. They may use automated testing tools, real-world simulations, and user testing to gather data.

-

User validation: The prototype is put in front of real users to gather feedback on usability, desirability, and value. This may involve interviews, surveys, or observational studies. The team looks for both quantitative and qualitative insights.

-

Iteration planning: Based on the results of testing and user validation, the team plans the next iteration of the prototype. They prioritize changes and improvements based on the feedback and align on the goals for the next cycle.

The team repeats steps 3-7 in short iterations until they have a prototype that meets the product requirements and is ready for production. The number of iterations required depends on the complexity of the product and the specific challenges encountered.

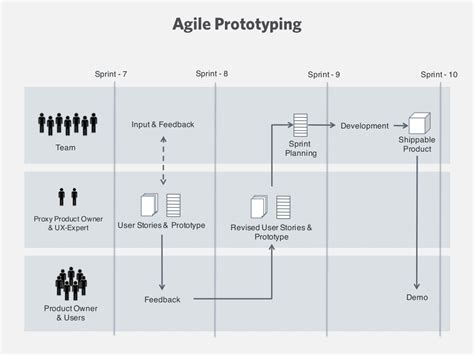

Throughout the process, the team holds regular meetings to discuss progress, challenges, and next steps. Common agile ceremonies include:

- Stand-up meetings: Brief daily meetings where each team member shares what they worked on yesterday, what they plan to work on today, and any blockers they face.

- Sprint planning: At the start of each iteration, the team meets to prioritize and plan the work for the upcoming sprint.

- Sprint review: At the end of each iteration, the team demonstrates the working prototype to stakeholders and gathers feedback.

- Retrospective: The team reflects on the previous iteration and identifies opportunities for improvement in their process and collaboration.

Effective agile prototyping requires a dedicated, co-located team with all the necessary skills and resources. The team should have access to rapid prototyping tools, test equipment, and a physical space to work together. Strong communication and collaboration skills are essential.

Challenges of Agile Hardware Prototyping

While agile prototyping offers many benefits, hardware development poses some unique challenges compared to software. These include:

-

Longer iteration cycles: Hardware iterations often take longer than software sprints due to the time required for physical fabrication, assembly, and testing. It’s not uncommon for hardware iterations to last 4-6 weeks or more.

-

Higher costs: Each hardware iteration requires money for components, materials, and fabrication. Costs can quickly add up, especially for complex products. Teams need to carefully manage budgets and prioritize features.

-

Physical constraints: Hardware products must obey the laws of physics and work within real-world constraints like size, weight, power consumption, and environmental factors. This can limit design flexibility and require more upfront planning.

-

Supply chain dependencies: Hardware teams often rely on external suppliers for components, PCBs, and other parts. Lead times can be long and unpredictable, which can delay prototype builds. Teams need to plan ahead and communicate closely with suppliers.

-

Tooling and equipment: Hardware development requires specialized tools and equipment for prototyping, testing, and assembly. This can include expensive items like 3D printers, CNC machines, oscilloscopes, and environmental chambers. Teams need access to the right tools and the skills to use them effectively.

Despite these challenges, many hardware teams have successfully adopted agile prototyping and seen significant benefits. The key is to tailor the approach to the specific needs of the product and the team, and to continuously learn and adapt.

Best Practices for Agile Hardware Prototyping

Here are some best practices for implementing agile prototyping in hardware development:

-

Start with a clear product vision: Before starting prototyping, ensure the team has a shared understanding of the product goals, target users, and key requirements. Use techniques like user personas, story mapping, and value proposition canvases to align the team.

-

Embrace a minimum viable prototype (MVP) mindset: Rather than trying to build the perfect prototype right away, focus on the smallest set of features that will allow you to validate the core hypotheses and gather useful feedback. Prioritize ruthlessly and be willing to cut scope.

-

Leverage rapid prototyping techniques: Use tools and techniques that allow you to quickly fabricate and assemble prototypes. This includes 3D printing, laser cutting, CNC machining, and modular electronics platforms like Arduino and Raspberry Pi.

-

Design for manufacturability: Even in early prototypes, consider how the product will eventually be manufactured at scale. Involve manufacturing and supply chain experts early to identify potential issues and optimize designs for production.

-

Use modular architectures: Break the product down into modular subsystems that can be developed and tested independently. This allows for parallel work streams and faster iterations. Use interface contracts to ensure smooth integration.

-

Invest in automated testing: Develop automated tests for hardware components and subsystems to catch issues early and reduce manual testing time. Use techniques like boundary scanning, JTAG testing, and hardware-in-the-loop simulation.

-

Collaborate closely with users: Involve users throughout the prototyping process, not just at the end. Use techniques like co-design workshops, user diaries, and contextual inquiries to gather rich insights. Share prototypes early and often to get feedback.

-

Prioritize learning over perfection: Embrace the opportunity to learn from failures and iterate based on feedback. Don’t get too attached to any particular design or solution. Be willing to pivot if needed.

-

Foster a culture of experimentation: Encourage the team to take calculated risks, try new ideas, and push the boundaries of what’s possible. Celebrate learning and iteration, not just success.

-

Continuously improve the process: Use retrospectives to regularly reflect on what’s working well and what could be improved in the team’s process and collaboration. Experiment with new techniques and tools to optimize the flow of value.

Implementing these best practices requires a shift in mindset and a willingness to embrace change. It may take time and practice for teams to fully adopt an agile prototyping approach, but the benefits can be significant.

Tools and Techniques for Agile Hardware Prototyping

Agile hardware prototyping relies on a variety of tools and techniques to enable rapid iteration and learning. Here are some common ones:

Rapid Prototyping Tools

-

3D printing: Additive manufacturing techniques like fused deposition modeling (FDM) and stereolithography (SLA) allow teams to quickly fabricate physical parts from digital CAD models. This is useful for prototyping enclosures, mechanical components, and even functional parts.

-

Laser cutting: Laser cutters can quickly cut and engrave flat sheet materials like acrylic, wood, and cardboard. This is useful for creating enclosures, panels, and 2D mechanical parts.

-

CNC machining: Computer numerical control (CNC) machines can automatically mill, drill, and cut metal and plastic parts based on digital designs. This is useful for creating high-precision mechanical components and molds.

-

PCB fabrication: Rapid PCB Prototyping services can quickly fabricate custom printed circuit boards based on digital designs. This allows teams to test and iterate on electronic subsystems.

Prototyping Platforms

-

Arduino: An open-source electronics platform that includes microcontroller boards, development software, and a large community of users and resources. Arduino is widely used for prototyping IoT devices, robots, and other interactive systems.

-

Raspberry Pi: A small, low-cost computer that can run Linux and be used for a variety of applications. Raspberry Pi is often used for prototyping more complex systems that require a full operating system and high-level programming languages.

-

Modular electronics: Platforms like littleBits and Grove provide plug-and-play electronic modules that can be easily snapped together to create functional prototypes without soldering or complex wiring.

Collaboration and Project Management Tools

-

Agile project management software: Tools like Jira, Trello, and Asana help teams plan, track, and collaborate on agile hardware projects. They provide features like user stories, task boards, burndown charts, and integration with other tools.

-

Product lifecycle management (PLM) software: PLM tools like Upchain, Fusion Lifecycle, and Duro help manage the end-to-end product development process, including requirements management, CAD data management, BOM management, and change control.

-

Communication and file sharing: Tools like Slack, Microsoft Teams, and Google Drive enable real-time communication and file sharing among team members, even if they are not co-located.

Testing and Validation Tools

-

Automated testing tools: Hardware testing tools like boundary scanners, JTAG testers, and hardware-in-the-loop simulators can automate testing of electronic components and subsystems, reducing manual effort and catching issues early.

-

Data acquisition systems: Tools like National Instruments DAQ and LabVIEW can capture and analyze data from sensors and instruments during prototype testing, enabling teams to validate performance and reliability.

-

User testing platforms: Tools like UserTesting and UsabilityHub allow teams to quickly gather feedback from target users on prototypes, even if they are not able to conduct in-person testing.

The specific tools and techniques used will depend on the needs of the product and the team. The key is to select tools that enable rapid iteration, collaboration, and learning.

Case Studies of Successful Agile Hardware Prototyping

Many companies, from startups to large enterprises, have successfully used agile prototyping to develop innovative hardware products. Here are a few examples:

Tesla Model 3

Tesla used agile prototyping to develop the Model 3, its first mass-market electric car. The company set an ambitious goal of producing 5,000 cars per week, which required a highly iterative and flexible approach.

Tesla used a variety of rapid prototyping techniques, including 3D printing, CNC machining, and modular electronics, to quickly test and refine designs. They also heavily leveraged simulation and virtual prototyping to validate designs before building physical prototypes.

Tesla’s agile approach allowed them to go from concept to production in just over two years, a remarkable feat for a complex automotive product. While the company faced challenges with scaling up production, they were able to quickly iterate and improve the design based on real-world feedback.

Saildrone

Saildrone is a company that makes autonomous ocean drones for scientific research and commercial applications. The company used agile prototyping to quickly develop and test its innovative sailboat-like drones.

Saildrone’s prototyping process involved rapid iterations of the hull design, electronics, and software. They used 3D printing to create scale models of the hull for hydrodynamic testing, and modular electronics to quickly test different sensor configurations.

The company also heavily leveraged simulation and real-world testing to validate the performance and reliability of the drones. They conducted extensive ocean trials to gather data and refine the design.

Saildrone’s agile approach allowed them to quickly bring a disruptive new product to market and establish themselves as a leader in the ocean drone industry. They continue to use agile prototyping to develop new features and capabilities for their drones.

Dyson

Dyson is a company known for its innovative vacuum cleaners, fans, and other household appliances. The company has a long history of using agile prototyping to develop new products.

Dyson’s prototyping process involves rapid iterations of designs, with a focus on user feedback and real-world testing. They heavily leverage 3D printing and other rapid prototyping techniques to quickly create functional prototypes.

Dyson also invests heavily in testing and validation, with a dedicated team of engineers and technicians who put prototypes through rigorous performance and reliability testing. They have developed custom test rigs and equipment to simulate real-world conditions.

Dyson’s agile approach has allowed them to consistently bring innovative and high-quality products to market. They have a reputation for being able to quickly respond to changing customer needs and preferences.

These case studies demonstrate the power of agile prototyping for hardware development. By embracing rapid iteration, user feedback, and continuous learning, companies can create products that are both innovative and successful in the market.

Frequently Asked Questions

What is the difference between agile prototyping and traditional hardware development?

Traditional hardware development typically follows a linear, waterfall-style process with long upfront design phases and a big-bang integration and testing phase at the end. Agile prototyping, on the other hand, emphasizes short, iterative cycles of design, build, and test, with a focus on rapid feedback and continuous improvement.

How long does an agile hardware prototyping cycle typically take?

The length of an agile hardware prototyping cycle can vary depending on the complexity of the product and the specific prototyping techniques used. However, a typical cycle might last anywhere from one to four weeks, with the goal of producing a working prototype that can be tested and validated with users.

What are the key roles in an agile hardware prototyping team?

An agile hardware prototyping team typically includes a mix of engineers (electrical, mechanical, firmware), designers, and project managers. Key roles may include:

- Product owner: Defines the product vision and prioritizes features based on user needs and business goals.

- Scrum master: Facilitates the agile process and removes barriers for the team.

- Hardware engineers: Design and develop the electronic and mechanical components of the prototype.

- Firmware engineers: Develop the low-level software that controls the hardware components.

- UX/UI designers: Design the user interface and user experience of the product.

- Test engineers: Develop and execute test plans to validate the functionality and reliability of the prototype.

What are some common challenges with agile hardware prototyping?

Some common challenges with agile hardware prototyping include:

- Longer iteration cycles compared to software due to the time required for physical fabrication and assembly.

- Higher costs associated with physical materials and components.

- Physical constraints and dependencies that limit design flexibility.

- Supply chain issues and long lead times for components and fabrication.

- Limited access to specialized tools and equipment required for prototyping and testing.

How do I get started with agile hardware prototyping?

To get started with agile hardware prototyping, consider the following steps:

- Assemble a cross-functional team with the necessary skills and expertise.

- Define the product vision and high-level requirements based on user needs and business goals.

- Break down the product into smaller, testable chunks that can be prototyped and validated independently.

- Select the appropriate prototyping tools and techniques based on the needs of

No responses yet