What is a Gerber File?

A Gerber file is a standard file format used in the printed circuit board (PCB) industry to describe the printed circuit board images, which includes copper layers, solder mask, legend, drill data, and other manufacturing information. It is a vector image file format that uses ASCII characters to describe the layout of a PCB.

Gerber files are named after the Gerber Systems Corp., the company that originally developed the file format in the 1960s. The current standard is known as RS-274X or Extended Gerber.

Components of a Gerber File

A Gerber file consists of several components that together provide a complete description of a PCB:

| Component | Description |

|---|---|

| Copper Layers | These files describe the copper traces, pads, and polygons on each layer of the PCB. |

| Solder Mask | These files define the areas of the PCB that will be covered with solder mask, which is a protective coating that prevents solder from bridging between adjacent pads. |

| Silkscreen | Also known as the legend, these files define the text and graphics that will be printed on the PCB for component placement and identification. |

| Drill Data | These files specify the location, size, and type of drills needed for the PCB. |

| Apertures | These files define the shapes and sizes of the pads, traces, and other features on the PCB. |

Why Use Gerber Files?

Gerber files are the industry standard for PCB manufacturing because they provide a reliable and accurate way to transfer PCB design data from the design software to the manufacturing process. Here are some of the key benefits of using Gerber files:

1. Universality

Gerber files can be read by virtually any PCB manufacturer, regardless of the design software used to create the files. This makes it easy to switch between manufacturers or to get quotes from multiple suppliers.

2. Accuracy

Gerber files provide a high degree of accuracy and precision, allowing manufacturers to produce PCBs that match the original design intent. The files use a vector image format that can represent features down to the micron level.

3. Reliability

Gerber files have been used in the PCB industry for decades and have proven to be a reliable way to transfer design data. The format has evolved over time to incorporate new features and capabilities, but the basic structure has remained the same.

4. Simplicity

Despite their accuracy and reliability, Gerber files are relatively simple and easy to generate from most PCB design software. The files use ASCII characters and have a straightforward structure that can be easily parsed by manufacturing equipment.

How to Create Gerber Files

Creating Gerber files from your PCB design software is a straightforward process, but the exact steps will vary depending on the software you are using. Here is a general overview of the process:

Step 1: Complete Your PCB Design

Before generating Gerber files, make sure your PCB design is complete and error-free. This includes placing all components, routing all traces, and adding any necessary text and graphics.

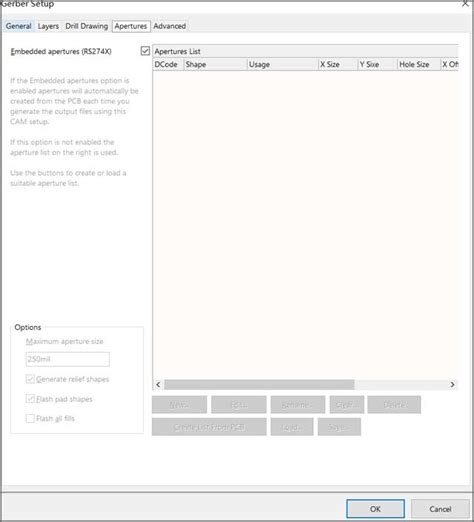

Step 2: Set Up Your Gerber Output

In your PCB design software, locate the Gerber output settings and configure them according to your manufacturer’s specifications. This may include specifying the file format, units, and aperture list.

Step 3: Generate the Gerber Files

Once your Gerber output settings are configured, generate the Gerber files for each layer of your PCB. This will typically include files for the copper layers, solder mask, silkscreen, and drill data.

Step 4: Review and Verify the Files

After generating the Gerber files, review them carefully to ensure they are complete and accurate. Many PCB design software packages include a Gerber Viewer that allows you to visually inspect the files before sending them to your manufacturer.

Step 5: Package and Send the Files

Package your Gerber files along with any other necessary design files (such as the bill of materials and assembly drawings) and send them to your PCB manufacturer. Most manufacturers accept Gerber files via email or through an online submission portal.

Common Gerber File Extensions

Gerber files use a variety of file extensions to indicate the type of data they contain. Here are some of the most common file extensions used in Gerber files:

| Extension | Description |

|---|---|

| .GBR | Generic Gerber file extension used for copper layers, solder mask, and silkscreen. |

| .GTL | Top (outer) copper layer. |

| .GBL | Bottom (outer) copper layer. |

| .G1 – .G99 | Inner copper layers (for multi-layer boards). |

| .GTS | Top solder mask layer. |

| .GBS | Bottom solder mask layer. |

| .GTO | Top silkscreen (overlay) layer. |

| .GBO | Bottom silkscreen (overlay) layer. |

| .GKO | Board outline layer. |

| .GM1 – .GM99 | Mechanical layers (for board fabrication data). |

| .GPT | Top pad master (for generating solder paste stencils). |

| .GPB | Bottom pad master (for generating solder paste stencils). |

| .DRL | NC drill file (in Excellon format). |

Gerber File Viewers and Editors

While Gerber files are primarily used for manufacturing, there are also several software tools available for viewing and editing Gerber files. These tools can be useful for inspecting files before sending them to a manufacturer, or for making minor tweaks to the design.

Gerber Viewers

Gerber viewers are software tools that allow you to visually inspect Gerber files without the need for a full PCB design suite. Some popular Gerber viewers include:

- GerbView (free, included with KiCad)

- ViewMate (free)

- CAM350 (paid)

Gerber Editors

Gerber editors are software tools that allow you to make changes to Gerber files directly, without going back to the original PCB design software. Some popular Gerber editors include:

- GerbTool (paid)

- PCB-GCODE (free)

- CAMtastic (paid)

It’s important to note that while Gerber editors can be useful for making minor tweaks, they should not be relied upon for major design changes. It’s always best to make significant changes in your PCB design software and then regenerate the Gerber files.

FAQ

Q1: Can I use Gerber files for 3D printing?

A1: No, Gerber files are specifically designed for PCB manufacturing and cannot be used for 3D printing. 3D printing typically uses file formats such as STL or OBJ.

Q2: Are Gerber files open source?

A2: While the Gerber file format is openly documented and widely used, it is not strictly open source. The format was originally developed by Gerber Systems Corp. (now owned by Ucamco) and has evolved over time through a process of industry collaboration and standardization.

Q3: Can I view Gerber files without specialized software?

A3: Gerber files are not designed to be human-readable and require specialized software (such as a Gerber viewer or PCB design suite) to view and interpret the data. However, there are several free Gerber viewers available that allow you to visually inspect the files.

Q4: What’s the difference between Gerber files and ODB++ files?

A4: Gerber files and ODB++ (Open Database++) files are both used for PCB manufacturing, but they differ in their structure and capabilities. Gerber files are individual files that each represent a single layer or aspect of the PCB (such as copper layers, solder mask, or drill data), while ODB++ is a single, unified database that contains all the necessary design information. ODB++ is a newer format that offers some advantages in terms of data integrity and ease of use, but Gerber remains the most widely used format in the industry.

Q5: Can I use Gerber files for PCB Assembly?

A5: Gerber files are primarily used for PCB fabrication (i.e., the manufacturing of the bare circuit board) and do not typically include all the information needed for PCB assembly (i.e., the placement and soldering of components onto the board). For assembly, additional files such as the bill of materials (BOM), centroid (pick-and-place) data, and assembly drawings are typically required. However, the Gerber files are still a critical part of the overall PCB manufacturing process.

No responses yet