What is a Flame Sensor?

A flame sensor is a device designed to detect the presence of a flame or fire. It works by sensing the infrared (IR), ultraviolet (UV), or visible light emitted by the flame. When a flame is detected, the sensor generates an electrical signal that can be used to trigger an alarm, activate a fire suppression system, or provide feedback to a control system.

Flame sensors come in various types, each with its own unique characteristics and applications. The most common types of flame sensors include:

1. Infrared (IR) Flame Sensors

IR flame sensors detect the infrared radiation emitted by flames. They are highly sensitive and can detect flames from a distance. IR flame sensors are commonly used in industrial settings, such as boilers, furnaces, and incinerators.

2. Ultraviolet (UV) Flame Sensors

UV flame sensors detect the ultraviolet radiation produced by flames. They are highly selective and can distinguish between flames and other light sources. UV flame sensors are often used in applications where false alarms need to be minimized, such as aircraft engines and gas turbines.

3. Visible Light Flame Sensors

Visible light flame sensors detect the visible light emitted by flames. They are less selective than IR and UV Sensors but can still provide reliable flame detection in certain applications. Visible light flame sensors are commonly used in residential fireplaces and gas stoves.

How Does a Flame Sensor Work?

The working principle of a flame sensor depends on the type of sensor being used. However, the basic concept remains the same: the sensor detects the presence of a flame by sensing the electromagnetic radiation emitted by the flame.

Infrared (IR) Flame Sensors

IR flame sensors work by detecting the infrared radiation emitted by flames. Flames emit a significant amount of infrared radiation, which can be detected by the sensor’s photocell. The photocell converts the infrared radiation into an electrical signal, which is then processed by the sensor’s electronics to determine the presence of a flame.

IR flame sensors typically have a wide field of view and can detect flames from a distance. They are also relatively immune to interference from ambient light sources, making them suitable for use in outdoor applications.

Ultraviolet (UV) Flame Sensors

UV flame sensors work by detecting the ultraviolet radiation produced by flames. Flames emit a small amount of ultraviolet radiation, which can be detected by the sensor’s UV-sensitive tube. The UV-sensitive tube contains a gas that ionizes when exposed to UV radiation, allowing current to flow through the tube.

UV flame sensors are highly selective and can distinguish between flames and other light sources. They are also fast-responding, making them suitable for applications where quick detection is essential.

Visible Light Flame Sensors

Visible light flame sensors work by detecting the visible light emitted by flames. Flames emit a significant amount of visible light, which can be detected by the sensor’s photocell. The photocell converts the visible light into an electrical signal, which is then processed by the sensor’s electronics to determine the presence of a flame.

Visible light flame sensors are less selective than IR and UV sensors but can still provide reliable flame detection in certain applications. They are commonly used in residential fireplaces and gas stoves, where the presence of a flame is expected and false alarms are less critical.

Flame Sensor Applications

Flame sensors find applications in a wide range of industries and settings. Some common applications of flame sensors include:

1. Industrial Combustion Monitoring

Flame sensors are extensively used in industrial combustion processes, such as boilers, furnaces, and incinerators. They help ensure efficient and safe combustion by monitoring the presence and quality of the flame. Flame sensors can detect flame failures, uneven combustion, and other anomalies, allowing operators to take corrective action before any damage occurs.

2. Fire Detection and Suppression

Flame sensors play a crucial role in fire detection and suppression systems. They can quickly detect the presence of a fire and trigger an alarm or activate a fire suppression system, such as a sprinkler or a gas suppression system. Flame sensors are commonly used in high-risk environments, such as oil and gas facilities, chemical plants, and aircraft hangars.

3. Residential Appliances

Flame sensors are also used in residential appliances, such as gas stoves, fireplaces, and water heaters. They help ensure safe and efficient operation by detecting the presence of a flame and shutting off the gas supply if the flame is extinguished.

4. Hobbyist Projects

Flame sensors are popular among hobbyists and makers for various projects involving fire detection and control. They can be used to create interactive art installations, fire-breathing robots, or even simple flame-based alarms.

Choosing the Right Flame Sensor

When selecting a flame sensor for your application, there are several factors to consider:

1. Sensor Type

As discussed earlier, there are three main types of flame sensors: infrared (IR), ultraviolet (UV), and visible light. Each type has its own strengths and weaknesses, and the choice depends on your specific application requirements.

| Sensor Type | Strengths | Weaknesses |

|---|---|---|

| Infrared (IR) | – Wide field of view – Long detection range – Immune to ambient light interference |

– Can be triggered by hot objects – Affected by dirt and dust accumulation |

| Ultraviolet (UV) | – Highly selective – Fast response time – Not affected by ambient light |

– Short detection range – Requires regular cleaning and maintenance |

| Visible Light | – Simple and inexpensive – Suitable for residential applications |

– Less selective – Can be triggered by other light sources |

2. Detection Range

The detection range of a flame sensor is the maximum distance at which it can reliably detect a flame. The required detection range depends on your application and the size of the area being monitored. Make sure to choose a sensor with a detection range that meets your needs.

3. Response Time

The response time of a flame sensor is the time it takes for the sensor to detect a flame and generate an output signal. In critical applications, such as fire suppression systems, a fast response time is essential to minimize damage and ensure safety.

4. Environmental Factors

Consider the environmental conditions in which the flame sensor will be operating. Factors such as temperature, humidity, dust, and vibration can affect the performance and reliability of the sensor. Choose a sensor that is suitable for your specific environment and has appropriate protection ratings.

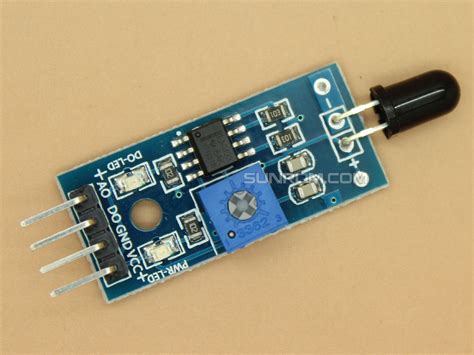

Installing and Configuring a Flame Sensor

Proper installation and configuration of a flame sensor are crucial for optimal performance and reliability. Here are some tips to help you get started:

1. Mounting Location

Choose a mounting location that provides a clear line of sight to the area being monitored. Avoid obstructions and ensure that the sensor is not exposed to direct sunlight or other light sources that could cause false alarms.

2. Wiring

Follow the manufacturer’s wiring instructions carefully. Use appropriate gauge wires and ensure that all connections are secure and properly insulated. If the sensor requires external power, make sure to provide a stable and regulated power supply.

3. Sensitivity Adjustment

Most flame sensors have a sensitivity adjustment feature that allows you to fine-tune the sensor’s response to different flame sizes and distances. Adjust the sensitivity according to your application requirements and test the sensor thoroughly to ensure reliable detection.

4. Integration with Control Systems

If the flame sensor is part of a larger control system, such as a fire suppression system or a process control system, ensure proper integration and communication between the sensor and the control system. Follow the manufacturer’s guidelines for configuring the sensor’s output signal and any necessary communication protocols.

Maintaining and Troubleshooting Flame Sensors

Regular maintenance and troubleshooting are essential to ensure the long-term reliability and performance of flame sensors. Here are some tips to help you keep your flame sensors in top condition:

1. Cleaning

Dust, dirt, and other contaminants can accumulate on the sensor’s lens or window, affecting its sensitivity and performance. Regularly clean the sensor’s optical components using a soft, lint-free cloth and a mild cleaning solution. Avoid using abrasive materials or harsh chemicals that could damage the sensor.

2. Calibration

Over time, the sensitivity of a flame sensor may drift, leading to false alarms or missed detections. Regularly calibrate the sensor according to the manufacturer’s guidelines to ensure accurate and reliable performance.

3. Troubleshooting

If a flame sensor is not working as expected, start by checking the power supply and wiring connections. Ensure that the sensor is receiving the correct voltage and that all connections are secure. If the problem persists, consult the manufacturer’s troubleshooting guide or contact their technical support for assistance.

Frequently Asked Questions (FAQ)

1. Can a flame sensor detect smoke?

No, flame sensors are designed to detect the presence of a flame, not smoke. For smoke detection, you would need a dedicated smoke detector.

2. How far can a flame sensor detect a flame?

The detection range of a flame sensor depends on the type of sensor and its specifications. IR flame sensors typically have the longest detection range, up to several meters, while UV and visible light sensors have shorter ranges.

3. Can a flame sensor be used outdoors?

Yes, many flame sensors are suitable for outdoor use. However, you should choose a sensor with appropriate environmental ratings and protection against the specific conditions in your application, such as temperature extremes, humidity, and dust.

4. How do I test a flame sensor?

To test a flame sensor, you can use a portable flame source, such as a lighter or a candle. Hold the flame in front of the sensor and check if it generates an output signal. Be sure to follow proper safety precautions and consult the manufacturer’s guidelines for specific testing procedures.

5. How long do flame sensors last?

The lifespan of a flame sensor depends on various factors, such as the type of sensor, the environment in which it operates, and the level of maintenance it receives. Most flame sensors have a lifespan of several years, but regular maintenance and calibration can help extend their useful life.

Conclusion

Flame sensors are vital components in many applications involving combustion monitoring and fire detection. By understanding the different types of flame sensors, their working principles, and their applications, you can make informed decisions when selecting and using these devices.

Remember to choose the right type of flame sensor for your specific application, considering factors such as detection range, response time, and environmental conditions. Proper installation, configuration, and maintenance are also crucial to ensure optimal performance and reliability.

By following the tips and tricks outlined in this guide, you can effectively use flame sensors to enhance safety, efficiency, and control in your projects and applications. Whether you are an industrial engineer, a fire protection specialist, or a hobbyist, mastering the art of flame sensing will undoubtedly benefit you in your endeavors.

No responses yet