What is a PCB watchdog timer?

A watchdog timer (WDT) is an electronic timer that is used to detect and recover from computer malfunctions. It is a hardware-based mechanism that monitors the operation of a microcontroller or other embedded system and resets the system if it detects a failure or error condition. The purpose of a watchdog timer is to improve the reliability and fault tolerance of the system by automatically restarting it if something goes wrong.

In a PCB design, the watchdog timer is typically implemented as a separate IC or as part of the microcontroller. Its purpose is to monitor the operation of the microcontroller and reset it if it detects that the microcontroller has become unresponsive or has entered an undesired state. This helps to prevent the system from becoming stuck in an infinite loop or hanging due to a software bug or other error.

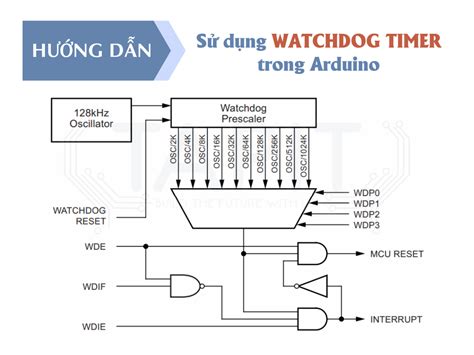

How Does a Watchdog Timer Work?

The basic operation of a watchdog timer is as follows:

- The watchdog timer is initialized and started by the microcontroller software during system startup.

- The microcontroller software must periodically reset the watchdog timer before it expires, typically by writing a specific value to a register or toggling a pin.

- If the microcontroller software fails to reset the watchdog timer before it expires, the watchdog timer generates a reset signal to the microcontroller, causing it to restart.

The timeout period of the watchdog timer is typically configurable and can range from a few milliseconds to several seconds, depending on the specific requirements of the application. The microcontroller software must be designed to reset the watchdog timer at appropriate intervals to prevent unnecessary resets while still providing adequate protection against system hangs and failures.

Benefits of Using a Watchdog Timer

There are several benefits to using a watchdog timer in a PCB design:

-

Improved reliability: A watchdog timer can help to improve the reliability of the system by automatically resetting the microcontroller if it becomes unresponsive or enters an undesired state. This can help to prevent system hangs and crashes, and ensure that the system continues to operate even in the presence of software bugs or other errors.

-

Increased fault tolerance: By automatically resetting the microcontroller in the event of a failure, a watchdog timer can help to increase the fault tolerance of the system. This is especially important in safety-critical applications where a system failure could have serious consequences.

-

Simplified debugging: A watchdog timer can also be useful for debugging purposes. If the system resets unexpectedly, the watchdog timer can provide a clear indication of where the problem occurred, making it easier to identify and fix the root cause of the issue.

Choosing the Right Watchdog Timer for Your PCB Design

When selecting a watchdog timer for your PCB design, there are several factors to consider:

Timeout Period

The timeout period of the watchdog timer should be chosen based on the specific requirements of your application. If the timeout period is too short, the watchdog timer may generate unnecessary resets, while if it is too long, it may not provide adequate protection against system hangs and failures.

The following table provides some general guidelines for selecting an appropriate timeout period:

| Application Type | Recommended Timeout Period |

|---|---|

| Safety-critical | 1-10 ms |

| Real-time | 10-100 ms |

| General-purpose | 100 ms – 1 s |

Reset Type

Watchdog timers can generate different types of reset signals, such as a hard reset or a soft reset. A hard reset completely restarts the microcontroller and clears all of its registers and memory, while a soft reset only restarts the program execution without affecting the microcontroller’s hardware state.

The choice between a hard reset and a soft reset depends on the specific requirements of your application. A hard reset may be necessary in safety-critical applications where a complete system restart is required, while a soft reset may be sufficient for general-purpose applications where a partial restart is acceptable.

Interface

Watchdog timers can be interfaced with the microcontroller in different ways, such as through a dedicated pin or a register-based interface. The choice of interface depends on the specific microcontroller and watchdog timer being used, as well as the PCB layout and other design constraints.

Some common interface options include:

- Dedicated WDT pin: The watchdog timer is connected to a dedicated pin on the microcontroller, which must be toggled periodically to reset the watchdog timer.

- Register-based interface: The watchdog timer is accessed through a register-based interface, where specific values must be written to a register to reset the watchdog timer.

- I2C or SPI interface: The watchdog timer is connected to the microcontroller through an I2C or SPI interface, which allows for more flexible configuration and control of the watchdog timer.

Implementing a Watchdog Timer in Your PCB Design

Once you have selected an appropriate watchdog timer for your application, the next step is to implement it in your PCB design. Here are some tips for implementing a watchdog timer:

Placement

The placement of the watchdog timer on the PCB is important for ensuring reliable operation. The watchdog timer should be placed close to the microcontroller to minimize the risk of signal integrity issues, and should be powered from a stable power supply to ensure accurate timing.

Power Supply

The power supply for the watchdog timer should be separate from the main power supply for the microcontroller to ensure that the watchdog timer continues to operate even if the main power supply fails. A separate power supply also helps to minimize the risk of noise and other interference that could affect the accuracy of the watchdog timer.

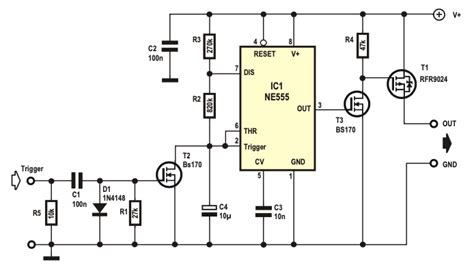

Reset Circuit

The reset circuit for the watchdog timer should be designed to ensure a clean and reliable reset signal to the microcontroller. This typically involves using a dedicated reset IC or a simple RC circuit to generate a clean reset pulse.

Software Considerations

The software running on the microcontroller must be designed to work with the watchdog timer to ensure reliable operation. This typically involves the following:

- Initializing the watchdog timer during system startup and configuring its timeout period and other settings.

- Periodically resetting the watchdog timer at appropriate intervals to prevent unnecessary resets.

- Handling any reset events generated by the watchdog timer and taking appropriate action, such as logging the event or performing a system restart.

It is important to thoroughly test the watchdog timer functionality during development to ensure that it is working as expected and providing adequate protection against system failures.

Best Practices for Using Watchdog Timers

Here are some best practices for using watchdog timers in your PCB design:

-

Choose an appropriate timeout period: As discussed earlier, the timeout period of the watchdog timer should be chosen based on the specific requirements of your application. It should be long enough to allow for normal system operation without generating unnecessary resets, but short enough to provide adequate protection against system hangs and failures.

-

Use a separate power supply: The watchdog timer should be powered from a separate power supply from the main microcontroller to ensure that it continues to operate even if the main power supply fails.

-

Place the watchdog timer close to the microcontroller: The watchdog timer should be placed as close as possible to the microcontroller on the PCB to minimize the risk of signal integrity issues and ensure accurate timing.

-

Use a reliable reset circuit: The reset circuit for the watchdog timer should be designed to provide a clean and reliable reset signal to the microcontroller, using a dedicated reset IC or a simple RC circuit.

-

Test thoroughly: The watchdog timer functionality should be thoroughly tested during development to ensure that it is working as expected and providing adequate protection against system failures.

-

Consider using a windowed watchdog timer: A windowed watchdog timer is a type of watchdog timer that requires the microcontroller to reset the timer within a specific time window, rather than just before the timer expires. This can provide additional protection against system hangs and failures by ensuring that the microcontroller is operating within expected time constraints.

-

Use a watchdog timer with a built-in brown-out detector: Some watchdog timers include a built-in brown-out detector that can detect when the supply voltage drops below a certain threshold and generate a reset signal to the microcontroller. This can provide additional protection against power supply issues and ensure that the system remains operational even in the presence of power fluctuations.

FAQ

What is the difference between a watchdog timer and a regular timer?

A regular timer is used to generate periodic interrupts or trigger events at specific time intervals, while a watchdog timer is used to monitor the operation of the microcontroller and reset it if it becomes unresponsive or enters an undesired state. A watchdog timer is specifically designed to improve the reliability and fault tolerance of the system by automatically restarting it if something goes wrong.

Can a watchdog timer be implemented in software?

While it is possible to implement a watchdog timer in software, it is generally not recommended because a software-based watchdog timer can be affected by the same software bugs and errors that it is intended to protect against. A hardware-based watchdog timer is preferred because it operates independently of the microcontroller software and can provide more reliable protection against system failures.

What happens if the microcontroller fails to reset the watchdog timer?

If the microcontroller fails to reset the watchdog timer before it expires, the watchdog timer will generate a reset signal to the microcontroller, causing it to restart. This helps to ensure that the system remains operational even if the microcontroller becomes unresponsive or enters an undesired state.

How do I choose the right timeout period for my watchdog timer?

The timeout period of the watchdog timer should be chosen based on the specific requirements of your application. It should be long enough to allow for normal system operation without generating unnecessary resets, but short enough to provide adequate protection against system hangs and failures. The timeout period can range from a few milliseconds to several seconds, depending on the application.

Can a watchdog timer be used in safety-critical applications?

Yes, watchdog timers are commonly used in safety-critical applications where system reliability and fault tolerance are critical. In these applications, a watchdog timer can help to ensure that the system remains operational even in the presence of software bugs, hardware failures, or other issues that could cause the system to become unresponsive or enter an undesired state. However, it is important to carefully design and test the watchdog timer functionality to ensure that it provides adequate protection against system failures and meets the specific safety requirements of the application.

Conclusion

Implementing a watchdog timer in your PCB design can help to improve the reliability and fault tolerance of your system by automatically resetting the microcontroller if it becomes unresponsive or enters an undesired state. When selecting a watchdog timer for your application, it is important to consider factors such as the timeout period, reset type, and interface, and to follow best practices for placement, power supply, reset circuit design, and software integration.

By carefully designing and testing the watchdog timer functionality, you can ensure that your system remains operational even in the presence of software bugs, hardware failures, or other issues that could cause the system to fail. This is especially important in safety-critical applications where system reliability and fault tolerance are paramount.

Overall, incorporating a watchdog timer into your PCB design is a simple and effective way to improve the reliability and robustness of your system, and should be considered an essential part of any embedded system design.

No responses yet