What is ESD and Why is Proper Grounding Critical?

Electrostatic discharge, commonly known as ESD, is a sudden flow of electricity between two electrically charged objects. This rapid transfer of static charge can generate extremely high voltages, sometimes reaching several thousand volts. When ESD occurs, it can cause significant damage to electronic components, especially sensitive devices like integrated circuits (ICs) found on printed circuit boards (PCBs).

To protect PCBs from the damaging effects of ESD, proper grounding techniques must be implemented. Grounding provides a low-impedance path for the static charge to dissipate safely, preventing it from reaching and damaging sensitive components. Effective ESD grounding is essential for ensuring the reliability and longevity of electronic devices.

ESD Grounding Techniques for PCBs

Ground Planes

One of the most effective ESD grounding techniques for PCBs is the use of ground planes. A ground plane is a large area of copper that covers most of the PCB surface, usually on one or more layers. Ground planes provide a low-impedance path for static charges to dissipate, minimizing the risk of ESD damage.

When designing a PCB with a ground plane, it’s essential to ensure that the plane covers as much of the board as possible, especially in areas where sensitive components are located. The ground plane should also be connected to the main ground of the circuit through multiple vias, which are small holes drilled through the PCB that allow electrical connections between layers.

| Layer | Purpose |

|---|---|

| Top | Components and signal traces |

| Ground Plane | ESD protection and low-impedance ground |

| Power Plane | Distribute power to components |

| Bottom | Components and signal traces |

Table 1: Example of a 4-layer PCB stackup with a dedicated ground plane.

Grounding Sensitive Components

In addition to using ground planes, it’s crucial to properly ground sensitive components on the PCB. This can be achieved by connecting the ground pins of the components directly to the ground plane through short, low-impedance traces or vias.

When grounding sensitive components, it’s important to keep the following guidelines in mind:

- Keep ground traces as short as possible to minimize inductance.

- Use multiple vias to connect ground pins to the ground plane for increased reliability.

- Avoid routing ground traces near high-speed signal traces to prevent coupling.

| Component | Grounding Method |

|---|---|

| ICs | Ground pins connected to ground plane through vias |

| Connectors | Shell connected to ground plane |

| Switches | Ground terminal connected to ground plane |

Table 2: Grounding methods for common PCB Components.

ESD Protection Devices

Another effective way to protect PCBs from ESD is by using dedicated ESD protection devices. These devices are designed to quickly and safely dissipate static charges, preventing them from reaching sensitive components.

Common ESD protection devices include:

- Transient Voltage Suppressor (TVS) diodes

- Metal Oxide Varistors (MOVs)

- Gas Discharge Tubes (GDTs)

When selecting an ESD protection device, consider factors such as the maximum voltage and current ratings, response time, and capacitance. The device should be placed close to the potential ESD entry points, such as connectors or exposed pins, to ensure maximum protection.

| Device | Voltage Rating | Response Time | Capacitance |

|---|---|---|---|

| TVS Diode | 5-400 V | < 1 ns | 0.5-10 nF |

| MOV | 11-1800 V | 25-50 ns | 10-1000 pF |

| GDT | 75-600 V | 100-1000 ns | 0.5-2 pF |

Table 3: Comparison of common ESD protection devices.

Grounding External Connections

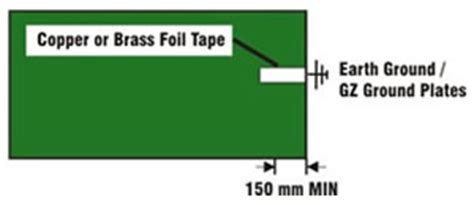

ESD can also enter a PCB through external connections, such as USB ports, Ethernet jacks, or power inputs. To prevent ESD damage from these sources, it’s essential to properly ground the connectors and provide adequate protection.

When designing external connections for ESD protection, consider the following:

- Use connectors with built-in ESD protection, such as USB Type-C connectors with shielding.

- Connect the connector shell or shield to the ground plane.

- Place ESD protection devices close to the connector pins.

| Connection | Grounding Method | Protection Device |

|---|---|---|

| USB | Shield connected to ground plane | TVS diode array |

| Ethernet | Shield connected to ground plane | Integrated magnetics with built-in protection |

| Power Input | Ground pin connected to ground plane | MOV or TVS diode |

Table 4: Grounding and protection methods for common external connections.

PCB Layout Considerations

Proper PCB layout is crucial for effective ESD grounding. When designing the layout, keep the following guidelines in mind:

- Place sensitive components away from potential ESD entry points.

- Route high-speed signals away from ESD protection devices to minimize capacitive coupling.

- Provide adequate spacing between traces to prevent ESD arc-over.

- Use guard rings or shielding for extra protection of sensitive areas.

| Layout Guideline | Purpose |

|---|---|

| Component Placement | Minimize ESD exposure |

| Trace Routing | Prevent coupling and arc-over |

| Spacing | Prevent arc-over |

| Shielding | Extra protection for sensitive areas |

Table 5: PCB layout guidelines for ESD protection.

Testing and Verification

After implementing ESD grounding techniques in your PCB design, it’s essential to test and verify the effectiveness of the protection. This can be done through various methods, such as:

- ESD gun testing: Applying controlled ESD pulses to the PCB and monitoring for failures.

- Surge testing: Subjecting the PCB to high-voltage surges and checking for damage.

- Continuity testing: Verifying that all ground connections are intact and low-impedance.

Regular testing and verification ensure that the ESD grounding measures are working as intended and that the PCB is adequately protected against static discharge.

Frequently Asked Questions (FAQ)

1. What is the difference between ESD and EMI?

ESD (Electrostatic Discharge) is a sudden flow of electricity between two charged objects, while EMI (Electromagnetic Interference) is the disruption of normal circuit operation due to electromagnetic fields. ESD is a single event that can cause immediate damage, while EMI is an ongoing issue that can degrade performance over time.

2. Can ESD damage occur even if there is no visible spark?

Yes, ESD damage can occur without a visible spark. Some ESD events, known as silent discharges, can have voltages below the threshold for creating a visible spark but still high enough to cause damage to sensitive components.

3. How much current is typically involved in an ESD event?

ESD events can involve currents ranging from a few amps to tens of amps, depending on the voltage and the discharge path. However, the duration of an ESD event is usually very short, typically less than 100 nanoseconds.

4. What is the most common cause of ESD damage during PCB assembly?

The most common cause of ESD damage during PCB assembly is human handling. The human body can easily accumulate static charges and discharge them when touching a PCB or component. To prevent this, assembly personnel should wear ESD-safe clothing and use grounded tools and workstations.

5. Can ESD protection devices interfere with normal circuit operation?

Some ESD protection devices, such as TVS diodes, can add capacitance to the circuit, which may interfere with high-speed signals. However, proper device selection and placement can minimize this effect. Designers should carefully consider the trade-offs between ESD protection and signal integrity when choosing protection devices.

Conclusion

Effective ESD grounding is essential for protecting PCBs from the damaging effects of static discharge. By implementing proper grounding techniques, such as using ground planes, grounding sensitive components, and incorporating ESD protection devices, designers can significantly reduce the risk of ESD damage.

Additionally, careful PCB layout and regular testing and verification are crucial for ensuring the long-term reliability and performance of electronic devices. By following the guidelines and best practices outlined in this article, engineers and designers can create PCBs that are robust and resistant to the challenges posed by ESD.

No responses yet