Introduction to Embedded IoT

Embedded systems and the Internet of Things (IoT) have revolutionized the electronics manufacturing industry. Embedded IoT combines the power of embedded systems with the connectivity and data exchange capabilities of IoT, enabling smart, connected, and efficient manufacturing processes. In this article, we will explore the role of embedded IoT in electronics manufacturing, its benefits, challenges, and future prospects.

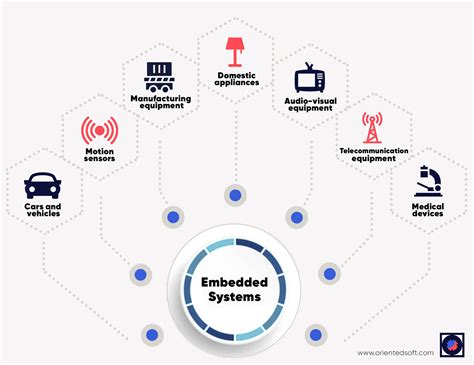

What are Embedded Systems?

Embedded systems are computer systems designed for specific functions within a larger system. They are typically microcontroller-based and have dedicated hardware and software components. Embedded systems are used in a wide range of applications, from consumer electronics to industrial automation.

| Characteristic | Description |

|---|---|

| Purpose-built | Designed for specific tasks and functions |

| Real-time | Able to respond to events and process data in real-time |

| Resource-constrained | Limited memory, processing power, and power consumption |

| Reliable | Designed for long-term, uninterrupted operation |

Types of Embedded Systems

-

Standalone Embedded Systems: These systems function independently without the need for a host system. Examples include digital watches and MP3 players.

-

Real-Time Embedded Systems: These systems have strict timing constraints and must respond to events within a specified time frame. Examples include airbag control systems and industrial control systems.

-

Networked Embedded Systems: These systems are connected to a network and can communicate with other devices. Examples include smart home devices and industrial sensors.

What is the Internet of Things (IoT)?

The Internet of Things (IoT) refers to the network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, and connectivity, enabling these objects to connect and exchange data. IoT allows devices to communicate and interact with each other, creating a smart and interconnected ecosystem.

Key Components of IoT

-

Sensors: Devices that collect data from the environment or object they are monitoring.

-

Connectivity: The network infrastructure that enables devices to communicate with each other and the cloud.

-

Data Processing: The ability to analyze and process the data collected by sensors to derive insights and make decisions.

-

User Interface: The means by which users can interact with and control IoT devices.

The Convergence of Embedded Systems and IoT

Embedded systems and IoT have converged to create a powerful combination that is transforming various industries, including electronics manufacturing. Embedded IoT enables devices to not only perform their specific functions but also communicate and exchange data with other devices and systems.

Benefits of Embedded IoT in Electronics Manufacturing

-

Enhanced Efficiency: Embedded IoT enables real-time monitoring and control of manufacturing processes, leading to increased efficiency and productivity.

-

Predictive Maintenance: By collecting and analyzing data from embedded sensors, manufacturers can predict when equipment is likely to fail and schedule maintenance proactively.

-

Quality Control: Embedded IoT allows for real-time quality monitoring and control, reducing defects and improving product quality.

-

Supply Chain Optimization: IoT-enabled tracking and monitoring of inventory and shipments leads to better supply chain visibility and optimization.

-

Customization and Flexibility: Embedded IoT enables manufacturers to quickly adapt to changing customer requirements and produce customized products.

Challenges and Considerations

While embedded IoT offers numerous benefits, there are also challenges and considerations that manufacturers must address:

-

Security: With increased connectivity comes increased security risks. Manufacturers must implement robust security measures to protect against cyber threats.

-

Data Privacy: The collection and processing of data raise concerns about data privacy. Manufacturers must ensure compliance with relevant regulations and protect sensitive information.

-

Interoperability: With diverse devices and systems, ensuring interoperability and seamless communication can be challenging.

-

Skill Gap: Implementing and maintaining embedded IoT systems requires specialized skills. Manufacturers must invest in training and hiring skilled professionals.

Future of Embedded IoT in Electronics Manufacturing

The future of embedded IoT in electronics manufacturing is promising. As technology continues to advance, we can expect to see:

-

Increased Adoption: More manufacturers will embrace embedded IoT to stay competitive and meet customer demands.

-

Edge Computing: The rise of edge computing will enable faster data processing and decision-making closer to the source of data.

-

Artificial Intelligence: The integration of AI with embedded IoT will enable more intelligent and autonomous manufacturing systems.

-

5G Networks: The deployment of 5G networks will provide faster and more reliable connectivity, enabling real-time data exchange and control.

Frequently Asked Questions (FAQ)

-

What is the difference between embedded systems and IoT?

Embedded systems are purpose-built computer systems designed for specific functions, while IoT refers to the network of connected devices that can exchange data. Embedded IoT combines the two, enabling embedded systems to communicate and exchange data with other devices and systems. -

How does embedded IoT benefit electronics manufacturing?

Embedded IoT enables real-time monitoring and control of manufacturing processes, predictive maintenance, quality control, supply chain optimization, and customization. It leads to increased efficiency, reduced defects, and improved customer satisfaction. -

What are the challenges in implementing embedded IoT in electronics manufacturing?

The challenges include ensuring security and data privacy, achieving interoperability among diverse devices and systems, and bridging the skill gap required to implement and maintain embedded IoT systems. -

What is the future outlook for embedded IoT in electronics manufacturing?

The future of embedded IoT in electronics manufacturing is promising, with increased adoption, the rise of edge computing, the integration of artificial intelligence, and the deployment of 5G networks. -

How can manufacturers get started with embedded IoT?

Manufacturers can start by identifying areas where embedded IoT can provide the most value, such as process monitoring, quality control, or predictive maintenance. They should assess their current infrastructure, define clear objectives, and partner with experienced technology providers to implement embedded IoT solutions.

Conclusion

Embedded IoT is transforming the electronics manufacturing industry, enabling smart, connected, and efficient manufacturing processes. By leveraging the power of embedded systems and IoT, manufacturers can improve efficiency, quality, and customer satisfaction while reducing costs and downtime. However, implementing embedded IoT also presents challenges that manufacturers must address, such as security, data privacy, interoperability, and the skill gap.

As technology continues to advance, the future of embedded IoT in electronics manufacturing looks bright. With increased adoption, edge computing, artificial intelligence, and 5G networks, we can expect to see more intelligent, autonomous, and responsive manufacturing systems.

To succeed in this new era of embedded IoT, manufacturers must embrace change, invest in the necessary infrastructure and skills, and collaborate with technology partners to unlock the full potential of embedded IoT in electronics manufacturing.

No responses yet