Introduction to DMOS Transistors

Double-diffused Metal Oxide Semiconductor (DMOS) transistors are a type of power MOSFET (Metal Oxide Semiconductor Field Effect Transistor) that are widely used in high-voltage and high-power applications. DMOS transistors are known for their ability to handle high currents and voltages while maintaining a relatively low on-resistance and fast switching speeds. These characteristics make DMOS transistors ideal for use in various power electronic applications, such as switch-mode power supplies, motor drives, and automotive electronics.

In this article, we will dive deep into the world of DMOS transistors, exploring their capabilities, structures, and applications. We will also discuss the advantages and limitations of DMOS transistors compared to other power transistor technologies.

How DMOS Transistors Work

Basic Principles of MOSFET Operation

To understand how DMOS transistors work, it is essential to first grasp the basic principles of MOSFET operation. MOSFETs are voltage-controlled devices that use an electric field to control the flow of current through a semiconductor channel. The basic structure of a MOSFET consists of a source, drain, and gate terminal, with the gate being electrically isolated from the channel by a thin layer of oxide.

When a voltage is applied to the gate terminal, an electric field is created that attracts or repels charge carriers (electrons or holes) in the semiconductor channel. This electric field modulates the conductivity of the channel, allowing the MOSFET to control the flow of current between the source and drain terminals.

Double-Diffused Structure

What sets DMOS transistors apart from other MOSFETs is their unique double-diffused structure. In a DMOS transistor, the channel region is formed by two separate diffusion processes, hence the name “double-diffused.”

The first diffusion process creates a lightly doped N-type region, known as the drift region, which extends from the drain to the channel. This drift region is designed to support high voltages and provide a low on-resistance when the transistor is in the on-state.

The second diffusion process creates a heavily doped P-type region, known as the body region, which forms the channel of the transistor. This body region is designed to provide a high threshold voltage and prevent the formation of a parasitic bipolar transistor, which can cause unwanted latch-up effects.

Vertical and Lateral DMOS Structures

DMOS transistors can be fabricated in two main structures: vertical DMOS (VDMOS) and lateral DMOS (LDMOS).

In a VDMOS structure, the current flows vertically from the drain (located at the bottom of the device) to the source (located at the top of the device). The gate is located on the top surface of the device, surrounded by the source region. This vertical structure allows for a high packing density and low on-resistance, making VDMOS transistors suitable for high-current applications.

In an LDMOS structure, the current flows laterally from the drain to the source, with both terminals located on the top surface of the device. The gate is located between the source and drain regions. LDMOS transistors have a lower packing density compared to VDMOS transistors but offer better high-frequency performance and are commonly used in RF power amplifiers.

Capabilities of DMOS Transistors

High Voltage Handling

One of the key capabilities of DMOS transistors is their ability to handle high voltages. The double-diffused structure, with its lightly doped drift region, allows DMOS transistors to support high breakdown voltages, typically ranging from tens to hundreds of volts. This high voltage capability makes DMOS transistors suitable for use in power conversion applications, such as switch-mode power supplies and motor drives, where high voltages need to be switched efficiently.

The breakdown voltage of a DMOS transistor is determined by the doping concentration and thickness of the drift region. By carefully controlling these parameters during the fabrication process, DMOS transistors can be designed to meet specific voltage requirements for different applications.

High Current Handling

In addition to their high voltage capability, DMOS transistors are also capable of handling high currents. The low on-resistance of DMOS transistors, combined with their ability to dissipate heat effectively, allows them to conduct large currents without excessive power losses or thermal stress.

The on-resistance of a DMOS transistor is determined by several factors, including the doping concentration and thickness of the drift region, the channel length and width, and the gate oxide thickness. By optimizing these parameters, DMOS transistors can achieve very low on-resistance values, typically in the milliohm range, which minimizes conduction losses and improves overall efficiency.

Fast Switching Speeds

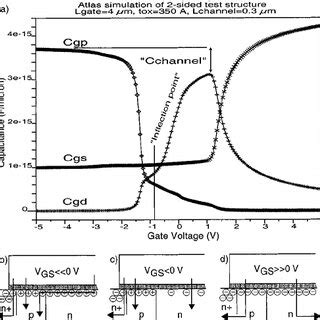

DMOS transistors are known for their fast switching speeds, which enable them to operate at high frequencies and minimize switching losses. The fast switching capability of DMOS transistors is due to their low input capacitance and low gate charge requirements.

The input capacitance of a DMOS transistor is the sum of the gate-to-source and gate-to-drain capacitances. By minimizing these capacitances through careful device design and layout, the time required to charge and discharge the gate can be reduced, resulting in faster switching speeds.

The gate charge of a DMOS transistor represents the amount of charge required to turn the device on or off. A low gate charge means that less energy is required to switch the transistor, which reduces switching losses and allows for higher operating frequencies.

Robustness and Reliability

DMOS transistors are designed to be robust and reliable, capable of withstanding harsh operating conditions and electrical stresses. The double-diffused structure of DMOS transistors provides inherent protection against various failure mechanisms, such as latch-up, avalanche breakdown, and electrostatic discharge (ESD).

Latch-up is a condition where a parasitic bipolar transistor is inadvertently turned on, causing a short circuit between the power supply and ground. The heavily doped body region in DMOS transistors helps prevent latch-up by suppressing the gain of the parasitic bipolar transistor.

Avalanche breakdown occurs when the electric field in the drift region becomes too high, causing a rapid increase in current flow. DMOS transistors are designed to have a high breakdown voltage and can withstand avalanche conditions for short periods without damage.

ESD Protection is essential for ensuring the reliability of DMOS transistors in real-world applications. DMOS transistors can be designed with built-in ESD protection structures, such as Zener Diodes or snap-back devices, which help dissipate ESD energy and prevent damage to the device.

DMOS Transistor Structures

Vertical DMOS (VDMOS)

Vertical DMOS (VDMOS) transistors are the most common type of DMOS transistor, widely used in power electronic applications. In a VDMOS transistor, the current flows vertically from the drain (located at the bottom of the device) to the source (located at the top of the device), with the gate located on the top surface, surrounded by the source region.

The key features of a VDMOS transistor include:

- Vertical current flow, allowing for high packing density and low on-resistance

- Lightly doped N-type drift region for high voltage handling

- Heavily doped P-type body region for high threshold voltage and latch-up suppression

- Planar or trench gate structure for improved performance and scalability

VDMOS transistors can be further classified into two sub-types based on their gate structure: planar VDMOS and trench VDMOS.

In a planar VDMOS transistor, the gate is formed on the top surface of the device, with the channel region located directly beneath the gate. This planar structure is simple to fabricate but may have limitations in terms of cell pitch and on-resistance scaling.

In a trench VDMOS transistor, the gate is formed in a trench etched into the semiconductor surface, with the channel region located along the vertical sidewalls of the trench. This trench structure allows for a higher cell density and lower on-resistance compared to planar VDMOS transistors, but may require more complex fabrication processes.

Lateral DMOS (LDMOS)

Lateral DMOS (LDMOS) transistors are another type of DMOS transistor, where the current flows laterally from the drain to the source, with both terminals located on the top surface of the device. The gate is located between the source and drain regions, controlling the current flow through the lateral channel.

The key features of an LDMOS transistor include:

- Lateral current flow, allowing for better high-frequency performance

- Lightly doped N-type drift region for high voltage handling

- Heavily doped P-type body region for high threshold voltage and latch-up suppression

- Compatible with standard CMOS fabrication processes

LDMOS transistors are commonly used in RF power amplifiers, where their lateral structure and high-frequency performance are advantageous. The lateral structure of LDMOS transistors allows for easy integration with other CMOS devices on the same chip, enabling the realization of complex RF power amplifier circuits.

However, LDMOS transistors have a lower packing density compared to VDMOS transistors, which limits their current handling capability and increases their on-resistance. As a result, LDMOS transistors are typically used in applications where high-frequency performance is more critical than high current handling.

Comparison of VDMOS and LDMOS Structures

The choice between VDMOS and LDMOS transistors depends on the specific requirements of the application. The following table summarizes the key differences between VDMOS and LDMOS transistors:

| Parameter | VDMOS | LDMOS |

|---|---|---|

| Current Flow | Vertical (drain to source) | Lateral (drain to source) |

| Packing Density | High | Low |

| On-Resistance | Low | High |

| Voltage Handling | High (tens to hundreds of volts) | High (tens to hundreds of volts) |

| Frequency Performance | Moderate | High |

| Fabrication Complexity | Moderate (planar) to high (trench) | Low (compatible with standard CMOS processes) |

| Typical Applications | Power conversion, motor drives | RF power amplifiers |

In general, VDMOS transistors are preferred for high-power, high-current applications where low on-resistance and high packing density are critical. LDMOS transistors, on the other hand, are favored for high-frequency applications where their lateral structure and compatibility with CMOS processes are advantageous.

Applications of DMOS Transistors

DMOS transistors find widespread use in various power electronic applications due to their high voltage and current handling capabilities, fast switching speeds, and robustness. Some of the key application areas for DMOS transistors include:

Switch-Mode Power Supplies (SMPS)

DMOS transistors are extensively used in switch-mode power supplies (SMPS) as the main switching elements. In an SMPS, DMOS transistors are used to efficiently convert the input DC Voltage to a regulated output DC voltage by rapidly switching the transistors on and off. The high voltage and current handling capabilities of DMOS transistors, combined with their fast switching speeds, make them ideal for use in SMPS applications.

VDMOS transistors, in particular, are commonly used in SMPS due to their low on-resistance and high packing density, which help minimize conduction losses and improve overall efficiency. The high breakdown voltage of VDMOS transistors also allows for the design of SMPS with a wide input voltage range and high output power levels.

Motor Drives

DMOS transistors are also widely used in motor drive applications, where they serve as the main power switches for controlling the speed and torque of electric motors. In a motor drive, DMOS transistors are used to convert the input DC voltage into a variable-frequency AC voltage that is applied to the motor windings.

The high voltage and current handling capabilities of DMOS transistors are essential for motor drive applications, as they need to withstand the high voltages and currents associated with motor operation. The fast switching speeds of DMOS transistors also enable precise control of the motor speed and torque, improving the overall performance and efficiency of the motor drive system.

Automotive Electronics

DMOS transistors are increasingly used in automotive electronic applications, such as engine control units, power steering systems, and lighting control modules. In these applications, DMOS transistors are used to switch high currents and voltages in a reliable and efficient manner, while also being able to withstand the harsh operating conditions encountered in automotive environments.

The robustness and reliability of DMOS transistors, with their built-in protection against various failure mechanisms, make them well-suited for automotive applications. The high voltage handling capability of DMOS transistors also allows for the design of automotive electronic systems with a wide input voltage range, accommodating the voltage fluctuations commonly encountered in vehicle electrical systems.

RF Power Amplifiers

LDMOS transistors are widely used in RF power amplifiers, particularly in base stations for wireless communication systems. In an RF power amplifier, LDMOS transistors are used to amplify the RF signal to the desired output power level while maintaining high efficiency and linearity.

The lateral structure and high-frequency performance of LDMOS transistors make them well-suited for RF power amplifier applications. The compatibility of LDMOS transistors with standard CMOS fabrication processes also allows for the integration of the power amplifier with other RF circuitry on the same chip, enabling the realization of compact and cost-effective RF front-end modules.

Advantages and Limitations of DMOS Transistors

Advantages

- High voltage handling capability, enabling the design of power electronic systems with a wide input voltage range and high output power levels

- High current handling capability, allowing for efficient switching of large currents with minimal conduction losses

- Fast switching speeds, enabling high-frequency operation and precise control of power electronic systems

- Low on-resistance, minimizing conduction losses and improving overall efficiency

- Robustness and reliability, with built-in protection against various failure mechanisms such as latch-up, avalanche breakdown, and ESD

- Compatibility with standard CMOS fabrication processes (for LDMOS transistors), enabling the integration of power devices with other circuitry on the same chip

Limitations

- Higher fabrication complexity compared to other power transistor technologies, particularly for VDMOS transistors with trench gate structures

- Larger device size compared to other power transistor technologies, such as gallium nitride (GaN) and silicon carbide (SiC) devices, which can limit the maximum achievable power density

- Lower high-frequency performance compared to GaN and SiC devices, which can limit their use in very high-frequency applications

- Higher gate charge requirements compared to GaN and SiC devices, which can increase switching losses and limit the maximum switching frequency

- Temperature-dependent performance, with the on-resistance and switching speed of DMOS transistors being affected by changes in operating temperature

Despite these limitations, DMOS transistors remain a popular choice for many power electronic applications due to their proven reliability, wide availability, and well-established manufacturing processes. The ongoing development of DMOS transistor technology, including improvements in device design and fabrication techniques, continues to push the boundaries of their performance and capabilities.

Frequently Asked Questions (FAQ)

-

What is a DMOS transistor?

A DMOS (Double-Diffused Metal Oxide Semiconductor) transistor is a type of power MOSFET that uses a double-diffused structure to achieve high voltage and current handling capabilities, fast switching speeds, and low on-resistance. -

What are the main differences between VDMOS and LDMOS transistors?

VDMOS (Vertical DMOS) transistors have a vertical current flow from the drain to the source, allowing for high packing density and low on-resistance. LDMOS (Lateral DMOS) transistors have a lateral current flow, offering better high-frequency performance and compatibility with standard CMOS fabrication processes. -

What are the key applications of DMOS transistors?

DMOS transistors are widely used in power electronic applications, such as switch-mode power supplies (SMPS), motor drives, automotive electronics, and RF power amplifiers. -

What are the advantages of DMOS transistors?

The advantages of DMOS transistors include high voltage and current handling capabilities, fast switching speeds, low on-resistance, robustness and reliability, and compatibility with standard CMOS fabrication processes (for LDMOS transistors). -

What are the limitations of DMOS transistors?

The limitations of DMOS transistors include higher fabrication complexity (particularly for VDMOS transistors with trench gate structures), larger device size compared to other power transistor technologies, lower high-frequency performance compared to GaN and SiC devices, higher gate charge requirements, and temperature-dependent performance.

Conclusion

DMOS transistors are a versatile and widely used type of power transistor, offering high voltage and current handling capabilities, fast switching speeds, and low on-resistance. The double-diffused structure of DMOS transistors, with its lightly doped drift region and heavily doped body region, enables them to achieve these desirable characteristics while maintaining robustness and reliability.

The two main types of DMOS transistors, VDMOS and LDMOS, offer distinct advantages and are suited for different applications. VDMOS transistors are preferred for high-power, high-current applications where low on-resistance and high packing density are critical, while LDMOS transistors are favored for high-frequency applications where their

No responses yet