Introduction to DACs and DIY Audio

A Digital-to-Analog Converter, or DAC, is an essential component in any digital audio system. Its role is to convert digital audio data, typically in the form of PCM (Pulse Code Modulation), into an analog signal that can be amplified and played back through speakers or headphones. While there are many excellent commercial DACs available, building your own DIY DAC can be a rewarding and educational experience for audio enthusiasts.

Building a DIY DAC allows you to:

– Customize the design to your specific needs and preferences

– Learn about the inner workings of digital audio systems

– Potentially achieve better performance than commercial DACs at a lower cost

– Experience the satisfaction of creating something unique and personal

In this comprehensive guide, we’ll walk you through the process of building your own DIY DAC, from understanding the basic principles to selecting components, assembling the circuit, and fine-tuning the performance.

Understanding Digital Audio and PCM

Before diving into the specifics of building a DAC, it’s essential to understand the basics of digital audio and PCM.

What is PCM?

PCM, or Pulse Code Modulation, is a method of representing analog audio signals in digital form. In PCM, the continuous analog signal is sampled at regular intervals, and each sample is quantized to a discrete value within a fixed range. The number of bits used for quantization determines the resolution of the digital audio, with higher bit depths allowing for more precise representation of the original analog signal.

Common PCM formats include:

| Format | Bit Depth | Sample Rate |

|---|---|---|

| CD Audio | 16 bits | 44.1 kHz |

| DVD Audio | 24 bits | 96 kHz |

| Hi-Res | 24 bits | 192 kHz |

Sample Rate and Bit Depth

The sample rate determines how often the analog signal is measured, while the bit depth determines the resolution of each measurement. Higher sample rates and bit depths result in more accurate digital representations of the original analog signal, but also require more storage space and bandwidth.

The Nyquist-Shannon sampling theorem states that the sample rate must be at least twice the highest frequency present in the analog signal to avoid aliasing. For human hearing, which typically extends to around 20 kHz, this means a minimum sample rate of 40 kHz. CD audio, with its 44.1 kHz sample rate, slightly exceeds this requirement.

Key Components of a DAC

A DAC consists of several key components that work together to convert digital audio data into an analog signal. Understanding the role of each component is crucial when designing and building your own DIY DAC.

Digital Interface

The digital interface receives the digital audio data from the source device and prepares it for conversion. Common digital interfaces include:

- USB: Widely used in computer audio and supports high-resolution formats

- S/PDIF: Used in consumer audio equipment, transmitted over coaxial or optical cables

- I2S: A serial bus interface commonly used between digital audio devices

DAC Chip

The DAC chip is the heart of the converter, responsible for transforming the digital audio data into an analog signal. There are many different DAC chips available, each with its own strengths and weaknesses. Some popular DAC chips for DIY projects include:

| Chip | Manufacturer | Bit Depth | Sample Rate |

|---|---|---|---|

| PCM1794A | Texas Instruments | 24 bits | 192 kHz |

| ES9018 | ESS Technology | 32 bits | 384 kHz |

| WM8741 | Wolfson Microelectronics | 24 bits | 192 kHz |

When selecting a DAC chip for your project, consider factors such as cost, performance, power consumption, and compatibility with your chosen digital interface.

Analog Output Stage

The analog output stage takes the output from the DAC chip and prepares it for amplification. This typically involves buffering, filtering, and sometimes even adding gain. The design of the analog output stage can significantly impact the overall performance of the DAC, so careful attention must be paid to component selection and layout.

Key components in the analog output stage include:

– Op-amps: Provide buffering and gain

– Capacitors: Filter out high-frequency noise and DC offset

– Resistors: Set gain and bias currents

Power Supply

A clean and stable power supply is essential for optimal DAC performance. Noise and ripple in the power supply can introduce distortion and degrade the signal-to-noise ratio. When designing your DIY DAC, consider using separate power supplies for the digital and analog sections to minimize interference.

Voltage regulators, such as the LM317 and LM337, can be used to provide stable and low-noise power to the various components in the DAC. Proper decoupling and filtering of the power supply can further improve performance.

Designing Your DIY DAC

With a basic understanding of the key components, you can now start designing your own DIY DAC. The design process involves selecting components, creating a schematic, and laying out the printed circuit board (PCB).

Component Selection

When selecting components for your DIY DAC, consider the following factors:

– Performance: Choose components that meet or exceed your target specifications

– Compatibility: Ensure components are compatible with each other and your chosen DAC chip

– Cost: Balance performance and cost to stay within your budget

– Availability: Select components that are readily available and easy to source

Some recommended components for a DIY DAC include:

| Component | Model | Description |

|---|---|---|

| DAC Chip | PCM1794A | 24-bit, 192 kHz, high-performance |

| Op-Amp | OPA1612 | Low-noise, high-speed, FET-input |

| Regulator | LM317/LM337 | Adjustable positive/negative regulators |

| Capacitor | Mundorf M-Cap Supreme | High-quality, polypropylene film |

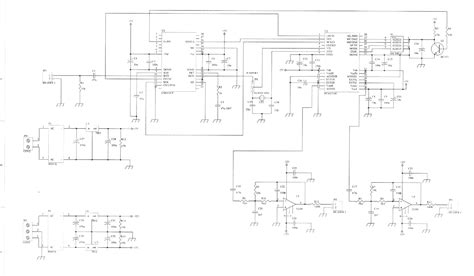

Schematic Design

Creating a schematic is the first step in translating your design into a physical circuit. A schematic is a graphical representation of the components and their interconnections in your DAC. There are many software tools available for schematic design, such as KiCad and Eagle.

When designing your schematic, consider the following:

– Power supply: Ensure proper decoupling and filtering of the power supply

– Grounding: Use a star ground topology to minimize ground loops and noise

– Signal paths: Keep sensitive analog signal paths short and away from noisy digital sections

– Component placement: Arrange components logically and minimize cross-talk

PCB Layout

Once your schematic is complete, you can move on to designing the PCB. The PCB layout is critical for optimal performance, as poor layout can introduce noise, distortion, and other unwanted artifacts.

When laying out your PCB, keep these guidelines in mind:

– Power planes: Use separate power planes for digital and analog sections

– Ground planes: Use a solid ground plane to provide a low-impedance return path

– Component placement: Place components to minimize signal path lengths and cross-talk

– Trace routing: Route traces to minimize inductance and avoid sharp bends

– Shielding: Use shielding techniques, such as guard rings and copper pours, to reduce EMI

There are many PCB design software tools available, such as KiCad and Altium Designer, that can help you create a professional-quality PCB layout.

Building Your DIY DAC

With your components selected and your PCB designed, you’re ready to start building your DIY DAC. The build process involves assembling the components on the PCB, testing and debugging the circuit, and finally, enclosing the DAC in a suitable case.

PCB Assembly

Before assembling your PCB, ensure you have the following tools and materials:

– Soldering iron and solder

– Solder wick or solder sucker for desoldering

– Flux for improved soldering

– Tweezers for handling small components

– Magnifying glass or microscope for inspecting solder joints

When assembling your PCB, follow these steps:

1. Start with the lowest-profile components, such as resistors and capacitors

2. Work your way up to taller components, such as op-amps and regulators

3. Pay attention to component orientation, especially for polarized components like diodes and electrolytic capacitors

4. Use a consistent soldering technique, applying just enough heat and solder to create a strong joint

5. Inspect each solder joint for quality and rework any suspect joints

Testing and Debugging

After assembling your PCB, it’s essential to test and debug the circuit before moving on to the final assembly. Testing involves verifying the basic functionality of the DAC, while debugging is the process of identifying and fixing any issues that arise during testing.

When testing your DIY DAC, follow these steps:

1. Visually inspect the PCB for any obvious issues, such as shorts, open circuits, or incorrect component placement

2. Apply power to the circuit and check for proper voltage levels at key points, such as the power supply rails and reference voltages

3. Connect a digital audio source and verify that the DAC is receiving and locking onto the input signal

4. Monitor the analog output with an oscilloscope or spectrum analyzer to check for any distortion, noise, or other anomalies

5. Listen to the DAC’s output through a high-quality amplifier and speakers or headphones to subjectively evaluate its performance

If you encounter any issues during testing, use a systematic debugging approach to isolate and resolve the problem. This may involve:

– Checking for proper power supply voltages and regulation

– Verifying correct component values and orientation

– Inspecting solder joints for quality and continuity

– Using signal tracing techniques to identify the source of the issue

Final Assembly

Once your DIY DAC is tested and debugged, you can move on to the final assembly. This involves enclosing the PCB in a suitable case and adding any necessary connectors and controls.

When selecting a case for your DAC, consider the following factors:

– Size: Ensure the case is large enough to accommodate the PCB and any additional components

– Material: Choose a case material that provides adequate shielding and mechanical protection

– Ventilation: Ensure the case has sufficient ventilation to prevent overheating

– Aesthetics: Select a case that complements your personal style and the intended use of the DAC

When adding connectors and controls, keep these guidelines in mind:

– Placement: Position connectors and controls logically and ergonomically

– Shielding: Use shielded connectors and cables to minimize EMI

– Isolation: Isolate the digital and analog sections to prevent cross-talk and interference

– Labeling: Clearly label all connectors and controls for ease of use

Fine-Tuning Your DIY DAC

After assembling your DIY DAC, you may want to fine-tune its performance to achieve the best possible sound quality. Fine-tuning involves making small adjustments to the circuit and components to optimize various aspects of the DAC’s performance.

Power Supply Optimization

The power supply is a critical component in any DAC, as it directly affects the noise floor and dynamic range of the analog output. To optimize your DAC’s power supply, consider the following:

– Voltage regulation: Use low-noise, high-PSRR (Power Supply Rejection Ratio) regulators to provide clean and stable power

– Decoupling: Use appropriate decoupling capacitors to filter out high-frequency noise and ripple

– Grounding: Implement a star ground topology to minimize ground loops and noise

Output Stage Optimization

The output stage of your DAC is responsible for buffering and filtering the analog signal before it is sent to the amplifier. To optimize the output stage, consider these techniques:

– Op-amp selection: Choose low-noise, high-speed op-amps with sufficient bandwidth and slew rate

– Passive components: Use high-quality, low-tolerance resistors and capacitors in the output stage

– DC blocking: Implement DC blocking capacitors to remove any DC offset from the output signal

– Bandwidth limiting: Use appropriate filtering to limit the bandwidth of the output signal and reduce high-frequency noise

Jitter Reduction

Jitter, or timing variations in the digital audio data, can negatively impact the performance of your DAC. To reduce jitter, consider the following techniques:

– Reclocking: Use a low-jitter clock source to reclock the digital audio data before it enters the DAC chip

– Isolation: Isolate the digital and analog sections of the DAC to prevent jitter from coupling into the analog signal path

– Asynchronous USB: Implement an asynchronous USB interface to minimize the impact of jitter from the source device

Conclusion

Building a DIY DAC can be a challenging but rewarding experience for audio enthusiasts. By understanding the basic principles of digital audio, selecting high-quality components, and paying attention to design and layout, you can create a DAC that rivals or even surpasses commercial offerings.

Remember to approach the process methodically, testing and debugging your circuit at each stage to ensure optimal performance. With patience, persistence, and a willingness to learn, you can build a DIY DAC that provides years of listening enjoyment and serves as a testament to your skills and dedication.

FAQ

1. What tools and equipment do I need to build a DIY DAC?

To build a DIY DAC, you’ll need the following tools and equipment:

– Soldering iron and solder

– Solder wick or solder sucker for desoldering

– Flux for improved soldering

– Tweezers for handling small components

– Magnifying glass or microscope for inspecting solder joints

– Multimeter for testing continuity and voltage levels

– Oscilloscope or spectrum analyzer for monitoring the analog output signal

2. Can I use any DAC chip in my DIY project?

While there are many DAC chips available, not all are suitable for DIY projects. When selecting a DAC chip, consider factors such as cost, performance, power consumption, and compatibility with your chosen digital interface. Some popular DAC chips for DIY projects include the PCM1794A, ES9018, and WM8741.

3. How important is the power supply in a DIY DAC?

The power supply is a critical component in any DAC, as it directly affects the noise floor and dynamic range of the analog output. A clean and stable power supply is essential for optimal DAC performance. When designing your DIY DAC, consider using separate power supplies for the digital and analog sections to minimize interference, and implement proper decoupling and filtering techniques.

4. What are some common issues encountered when building a DIY DAC?

Some common issues encountered when building a DIY DAC include:

– Incorrect component placement or orientation

– Poor solder joint quality, leading to shorts or open circuits

– Inadequate power supply decoupling or filtering, resulting in noise or ripple

– Improper grounding, causing ground loops or noise

– Insufficient shielding or isolation, leading to EMI or cross-talk between digital and analog sections

Careful design, attention to detail during assembly, and thorough testing and debugging can help minimize these issues.

5. How can I evaluate the performance of my DIY DAC?

There are several ways to evaluate the performance of your DIY DAC:

– Objective measurements: Use an oscilloscope or spectrum analyzer to measure parameters such as frequency response, distortion, noise floor, and dynamic range

– Subjective listening tests: Compare the sound quality of your DIY DAC to commercial offerings using high-quality amplifiers, speakers, or headphones

– Comparative analysis: Evaluate your DIY DAC against published specifications and measurements of well-regarded commercial DACs to gauge its relative performance

Ultimately, the true measure of your DIY DAC’s performance is your personal satisfaction with its sound quality and the knowledge and experience gained through the build process.

No responses yet