What are Digital Sensors?

Digital sensors are devices that convert physical quantities or phenomena into digital signals, which are discrete, quantized representations of the measured value. Unlike analog sensors, which produce a continuous output signal proportional to the measured quantity, digital sensors output a binary signal that can be directly interpreted by digital systems, such as microcontrollers or computers.

Advantages of Digital Sensors

Digital sensors offer several advantages over their analog counterparts:

- Immunity to noise: Digital signals are less susceptible to noise and interference compared to analog signals, ensuring more accurate and reliable measurements.

- Easy integration: Digital sensors can be easily interfaced with digital systems without the need for additional analog-to-digital converters (ADCs).

- Programmability: Many digital sensors can be programmed or calibrated using software, allowing for greater flexibility and adaptability.

- Multiplexing: Multiple digital sensors can be connected to a single digital input pin using multiplexing techniques, reducing the number of required input/output pins.

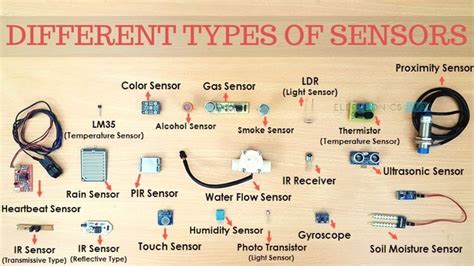

Types of Digital Sensors

There are numerous types of digital sensors, each designed to measure specific physical quantities or detect particular phenomena. Some of the most common digital sensors include:

1. Digital Temperature Sensors

Digital temperature sensors measure the ambient temperature and convert it into a digital signal. These sensors are widely used in various applications, such as:

- Environmental monitoring

- HVAC systems

- Consumer electronics (e.g., thermostats, refrigerators)

- Industrial process control

Examples of digital temperature sensors include:

- DS18B20: A popular 1-Wire digital temperature sensor with a temperature range of -55°C to +125°C and an accuracy of ±0.5°C.

- LM75: An I2C-compatible digital temperature sensor with a temperature range of -55°C to +125°C and an accuracy of ±2°C.

- TMP102: An I2C-compatible digital temperature sensor with a temperature range of -40°C to +125°C and an accuracy of ±0.5°C.

| Sensor | Interface | Temperature Range | Accuracy |

|---|---|---|---|

| DS18B20 | 1-Wire | -55°C to +125°C | ±0.5°C |

| LM75 | I2C | -55°C to +125°C | ±2°C |

| TMP102 | I2C | -40°C to +125°C | ±0.5°C |

2. Digital Humidity Sensors

Digital humidity sensors measure the relative humidity of the surrounding air and provide a digital output. These sensors are used in various applications, such as:

- Weather stations

- HVAC systems

- Agricultural monitoring

- Indoor air quality monitoring

Examples of digital humidity sensors include:

- DHT11: A low-cost digital humidity and temperature sensor with a humidity range of 20-90% RH and an accuracy of ±5% RH.

- DHT22: An improved version of the DHT11, with a humidity range of 0-100% RH and an accuracy of ±2% RH.

- HIH-6130: A high-accuracy digital humidity and temperature sensor with a humidity range of 0-100% RH and an accuracy of ±4% RH.

| Sensor | Humidity Range | Accuracy |

|---|---|---|

| DHT11 | 20-90% RH | ±5% RH |

| DHT22 | 0-100% RH | ±2% RH |

| HIH-6130 | 0-100% RH | ±4% RH |

3. Digital Pressure Sensors

Digital pressure sensors measure the pressure of gases or liquids and provide a digital output. These sensors are used in various applications, such as:

- Automotive systems (e.g., tire pressure monitoring)

- Medical devices (e.g., blood pressure monitors)

- Industrial process control

- Altitude measurement

Examples of digital pressure sensors include:

- BMP180: A digital barometric pressure sensor with a pressure range of 300-1100 hPa and an accuracy of ±1 hPa.

- MS5611: A high-resolution digital pressure sensor with a pressure range of 10-1200 mbar and an accuracy of ±1.5 mbar.

- MPL3115A2: A digital pressure sensor with altimeter functionality, a pressure range of 20-110 kPa, and an accuracy of ±0.4 kPa.

| Sensor | Pressure Range | Accuracy |

|---|---|---|

| BMP180 | 300-1100 hPa | ±1 hPa |

| MS5611 | 10-1200 mbar | ±1.5 mbar |

| MPL3115A2 | 20-110 kPa | ±0.4 kPa |

4. Digital Optical Sensors

Digital optical sensors detect the presence or absence of light, or measure the intensity of light, and provide a digital output. These sensors are used in various applications, such as:

- Proximity detection

- Ambient light sensing

- Optical encoders

- Gesture recognition

Examples of digital optical sensors include:

- APDS-9960: A digital RGB, ambient light, and gesture sensor with an I2C interface.

- TSL2561: A digital luminosity sensor with a wide dynamic range and an I2C interface.

- OPT3001: A high-precision digital ambient light sensor with an I2C interface and a wide dynamic range.

| Sensor | Features | Interface |

|---|---|---|

| APDS-9960 | RGB, ambient light, gesture | I2C |

| TSL2561 | Luminosity, wide dynamic range | I2C |

| OPT3001 | High-precision, wide dynamic range | I2C |

5. Digital Motion Sensors

Digital motion sensors detect and measure various types of motion, such as acceleration, rotation, or tilt, and provide a digital output. These sensors are used in various applications, such as:

- Inertial measurement units (IMUs)

- Activity tracking

- Robotics

- Gaming controllers

Examples of digital motion sensors include:

- MPU-6050: A digital 6-axis accelerometer and gyroscope sensor with an I2C interface.

- LSM9DS1: A digital 9-axis accelerometer, gyroscope, and magnetometer sensor with an I2C interface.

- BNO055: A digital 9-axis absolute orientation sensor with an I2C interface and on-board sensor fusion.

| Sensor | Axes | Features | Interface |

|---|---|---|---|

| MPU-6050 | 6 | Accelerometer, gyroscope | I2C |

| LSM9DS1 | 9 | Accelerometer, gyroscope, magnetometer | I2C |

| BNO055 | 9 | Absolute orientation, sensor fusion | I2C |

Applications of Digital Sensors

Digital sensors find applications in a wide range of fields, enabling automation, monitoring, and control of various processes. Some of the key application areas include:

1. Consumer Electronics

Digital sensors are widely used in consumer electronics to enhance user experience and enable smart features. Some examples include:

- Smartphones: Digital sensors like accelerometers, gyroscopes, and proximity sensors are used for screen orientation, gesture recognition, and power management.

- Wearables: Digital sensors like heart rate monitors, pedometers, and altimeters are used in smartwatches and fitness trackers to monitor user activity and health.

- Smart home devices: Digital sensors like temperature, humidity, and motion sensors are used in smart thermostats, security systems, and lighting control.

2. Industrial Automation

Digital sensors play a crucial role in industrial automation, enabling precise monitoring and control of various processes. Some examples include:

- Process control: Digital sensors like temperature, pressure, and flow sensors are used to monitor and control industrial processes, ensuring optimal performance and safety.

- Predictive maintenance: Digital sensors are used to monitor the condition of industrial equipment, enabling predictive maintenance and reducing downtime.

- Quality control: Digital sensors are used to inspect and measure products during manufacturing, ensuring consistent quality and reducing waste.

3. Automotive

Digital sensors are extensively used in the automotive industry to enhance safety, performance, and user experience. Some examples include:

- Engine management: Digital sensors like temperature, pressure, and oxygen sensors are used to optimize engine performance and reduce emissions.

- Advanced driver assistance systems (ADAS): Digital sensors like cameras, radar, and ultrasonic sensors are used in ADAS features like adaptive cruise control, lane departure warning, and parking assistance.

- Tire pressure monitoring: Digital pressure sensors are used to monitor tire pressure, improving safety and fuel efficiency.

4. Healthcare

Digital sensors are revolutionizing the healthcare industry, enabling remote monitoring, early diagnosis, and personalized treatment. Some examples include:

- Wearable medical devices: Digital sensors like ECG, SpO2, and glucose sensors are used in wearable devices to monitor patient health remotely.

- Medical imaging: Digital sensors are used in various medical imaging modalities, such as digital X-ray, CT, and MRI, to capture high-resolution images for diagnosis and treatment planning.

- Telemedicine: Digital sensors enable remote monitoring of patients, allowing for early intervention and reducing the need for hospital visits.

Frequently Asked Questions (FAQ)

1. What is the difference between digital and analog sensors?

Digital sensors output a discrete, quantized signal that can be directly interpreted by digital systems, while analog sensors output a continuous signal that needs to be converted to digital using an analog-to-digital converter (ADC).

2. What are the advantages of using digital sensors over analog sensors?

Digital sensors offer several advantages, including immunity to noise, easy integration with digital systems, programmability, and the ability to connect multiple sensors using multiplexing techniques.

3. How do I choose the right digital sensor for my application?

When choosing a digital sensor, consider factors such as the physical quantity to be measured, the required accuracy and resolution, the operating environment, and the compatibility with your existing system (e.g., communication interface, power requirements).

4. Can digital sensors be used in harsh environments?

Yes, many digital sensors are designed to operate in harsh environments, such as high temperatures, high pressures, or corrosive atmospheres. However, it is essential to choose sensors with appropriate ratings and protection for your specific application.

5. How do I interface a digital sensor with a microcontroller or computer?

Most digital sensors communicate using standard protocols like I2C, SPI, or UART, which can be easily interfaced with microcontrollers or computers. Refer to the sensor’s datasheet for the specific communication protocol and wiring requirements, and use the appropriate libraries or drivers for your development platform.

Conclusion

Digital sensors are essential components in a wide range of applications, enabling accurate and reliable measurement, monitoring, and control of various physical quantities. By understanding the working principles, types, and applications of digital sensors, engineers and developers can design and implement innovative solutions that leverage the power of these versatile devices. As technology continues to advance, we can expect to see even more sophisticated and specialized digital sensors, further expanding the possibilities for automation, monitoring, and control in various fields.

No responses yet