What is Tactile Wood?

Tactile wood refers to engineered wood materials that have been designed to provide enhanced tactile properties compared to natural wood. These materials aim to deliver a more engaging sensory experience through their texture, warmth, and overall feel.

Two prominent examples of tactile wood materials are Woodoo and Altium. Both offer unique approaches to enhancing the tactility of wood while maintaining or improving its strength, durability, and sustainability.

Woodoo: Transparent & Tactile Wood Material

Woodoo is a French startup that has developed a patented process for transforming wood into a translucent, tactile material. Their technology involves treating wood with a proprietary bio-based polymer that replaces the lignin and air in the wood’s cellular structure.

The resulting material, also called Woodoo, has several remarkable properties:

- Translucency: Woodoo allows light to pass through, creating a unique visual effect while maintaining the wood grain pattern.

- Tactility: The bio-polymer imparts a smooth, silky texture to the wood surface, making it inviting to touch.

- Strength: Woodoo is 3 times stronger than natural wood and has greater resistance to humidity and fire.

- Sustainability: The Woodoo process uses fast-growing wood species and bio-based polymers, making it an eco-friendly alternative to plastic and other synthetic materials.

Potential applications for Woodoo include furniture, interior design elements, automotive interiors, consumer electronics, and more. The company has already partnered with major brands like Chanel, Yamaha, and Hermès to explore incorporating Woodoo into their products.

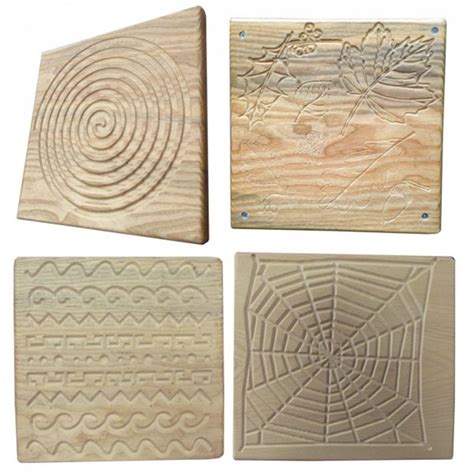

Altium: Haptically-Enhanced Wood Surfaces

Altium is a research project led by the Human-Computer Interaction group at Aalto University in Finland. Their focus is on developing wood surfaces with enhanced haptic feedback through embedded electronics.

The Altium approach involves integrating thin, flexible electronic circuits into wood veneers. These circuits can detect touch and gestures, as well as provide tactile feedback through vibration or slight surface deformation.

Some potential applications for Altium’s haptically-enhanced wood surfaces include:

- Interactive furniture: Tables or shelves that respond to touch, providing information or controls.

- Assistive devices: Tactile guidance systems for the visually impaired, using wood surfaces in public spaces.

- Artistic installations: Interactive wooden artworks that engage the sense of touch.

By combining the natural warmth and texture of wood with the interactivity of embedded electronics, Altium aims to create more intuitive and engaging interfaces for a variety of contexts.

The Science Behind Tactile Wood

Woodoo: Transforming Wood Structure

The Woodoo process leverages the natural cellular structure of wood to create its unique properties. Wood is composed of cellulose fibers bound together by lignin, with air-filled spaces (lumens) in between.

Woodoo’s bio-polymer treatment involves the following steps:

- Extraction: The lignin is selectively removed from the wood using a proprietary extraction process. This step also removes the air from the lumens.

- Impregnation: The wood is then impregnated with Woodoo’s bio-based polymer, which fills the spaces left by the extracted lignin and air.

- Stabilization: The polymer is stabilized within the wood structure, creating a strong, durable matrix.

The bio-polymer used by Woodoo is transparent, allowing light to pass through the treated wood. It also provides a smooth, tactile surface that is pleasant to touch.

| Property | Natural Wood | Woodoo |

|---|---|---|

| Translucency | Opaque | Translucent |

| Tactility | Rough, porous | Smooth, silky |

| Strength | – | 3x stronger |

| Humidity resistance | Low | High |

| Fire resistance | Low | High |

Altium: Integrating Electronics into Wood

Altium’s approach to tactile wood involves the integration of thin, flexible electronic circuits into wood veneers. This process requires careful consideration of the materials and fabrication methods to ensure compatibility and durability.

The key steps in creating Altium’s haptically-enhanced wood surfaces are:

- Circuit design: Thin, flexible circuits are designed to detect touch, gestures, and provide haptic feedback. These circuits are typically made of conductive polymers or metallic nanomaterials.

- Veneer preparation: Thin wood veneers are selected and prepared for circuit integration. The veneers must be smooth, uniform, and free of defects.

- Circuit integration: The flexible circuits are bonded to the wood veneer using a combination of heat, pressure, and adhesives. The goal is to achieve a seamless integration without compromising the wood’s appearance or tactile properties.

- Lamination: Multiple layers of circuit-embedded veneers can be laminated together to create thicker, more robust wood surfaces.

The resulting haptically-enhanced wood surfaces can detect various types of input and provide tactile feedback to the user. For example:

| Interaction | Detection | Feedback |

|---|---|---|

| Touch | Capacitive sensing | Vibration |

| Gesture | Proximity sensing | Surface deformation |

| Force | Pressure sensing | Resistance |

By integrating electronics into wood, Altium aims to create more intuitive and engaging interfaces that leverage the natural warmth and texture of the material.

Applications and Opportunities

Woodoo: Sustainable Luxury and Beyond

Woodoo’s unique combination of translucency, tactility, and strength opens up a wide range of potential applications. The company has initially focused on high-end, luxury markets where the aesthetic and sensory qualities of the material are highly valued.

Some examples of Woodoo applications include:

- Luxury furniture: Woodoo’s translucent, tactile wood can be used to create striking, one-of-a-kind furniture pieces for high-end interior design.

- Automotive interiors: The material’s strength, durability, and sensory properties make it well-suited for use in car interiors, such as dashboards, door panels, and trim elements.

- Consumer electronics: Woodoo can provide a warm, organic touch to electronic devices like smartphones, laptops, or wearables, setting them apart from cold, impersonal metals and plastics.

However, the potential for Woodoo extends beyond luxury applications. As the technology matures and production scales up, Woodoo could become a more widely accessible material, offering a sustainable alternative to plastics in various industries.

Altium: Enhancing Human-Computer Interaction with Wood

Altium’s haptically-enhanced wood surfaces have the potential to revolutionize the way we interact with digital devices and environments. By leveraging the natural warmth and familiarity of wood, Altium aims to create more intuitive and engaging interfaces.

Potential applications for Altium’s technology include:

- Smart furniture: Wooden tables, shelves, or storage units with embedded touch controls and haptic feedback could provide a more seamless and natural way to interact with our living spaces.

- Public installations: Tactile wood surfaces could be used in museums, libraries, or other public spaces to provide interactive information or wayfinding assistance, especially for the visually impaired.

- Education and play: Haptically-enhanced wood toys or learning tools could provide a more engaging and multisensory experience for children, promoting creativity and exploration.

As the field of human-computer interaction continues to evolve, the integration of tactile wood materials like Altium could play a significant role in shaping the future of our digital experiences.

Challenges and Future Developments

Scalability and Cost

One of the main challenges facing tactile wood materials like Woodoo and Altium is scalability. The processes involved in creating these materials are currently complex and time-consuming, which limits their production capacity and increases costs.

To overcome this challenge, researchers and companies are working on optimizing their production methods and exploring new technologies. For example:

- Automation: Automating key steps in the production process, such as wood treatment or circuit integration, could help increase efficiency and reduce costs.

- Material optimization: Identifying the most suitable wood species, polymers, and electronic materials for each application could help streamline the production process and improve performance.

- Modular design: Developing modular, plug-and-play components for tactile wood surfaces could simplify installation and maintenance, making them more accessible to a wider range of users.

As production scales up and costs come down, tactile wood materials could become a more viable option for a broader range of applications.

Durability and Maintenance

Another challenge for tactile wood materials is ensuring their long-term durability and ease of maintenance. Wood is a natural material that can be affected by factors like humidity, temperature, and wear over time.

To address this challenge, researchers are working on developing more robust and resilient wood treatments and coatings. For example:

- Protective coatings: Applying transparent, durable coatings to tactile wood surfaces could help protect them from moisture, scratches, and other types of damage.

- Self-healing materials: Incorporating self-healing polymers or other advanced materials into tactile wood could enable the surfaces to repair themselves when damaged, extending their lifespan.

- Modular replacement: Designing tactile wood surfaces with easily replaceable components could simplify maintenance and repair, allowing users to swap out damaged or outdated elements as needed.

By addressing durability and maintenance concerns, tactile wood materials could become a more reliable and long-lasting option for various applications.

Future Research and Innovation

As tactile wood materials continue to evolve, there are many exciting opportunities for future research and innovation. Some potential areas of exploration include:

- Advanced functionalities: Integrating additional sensing and actuation capabilities into tactile wood surfaces, such as temperature sensing, color changing, or shape-shifting, could open up new possibilities for interaction and design.

- Sustainable materials: Exploring the use of alternative, eco-friendly materials for tactile wood, such as recycled wood fibers or biodegradable polymers, could further enhance the sustainability of these materials.

- Hybrid materials: Combining tactile wood with other advanced materials, such as smart textiles or self-healing polymers, could create even more capable and adaptable surfaces for human-computer interaction.

- AI and machine learning: Incorporating artificial intelligence and machine learning algorithms into tactile wood interfaces could enable them to learn and adapt to individual users’ preferences and behaviors over time.

As researchers and innovators continue to push the boundaries of what is possible with tactile wood materials, we can expect to see even more exciting and transformative applications in the years to come.

FAQ

-

Q: Are tactile wood materials like Woodoo and Altium available for purchase?

A: Currently, Woodoo and Altium are in the research and development stage and are not widely available for purchase. However, Woodoo has partnered with several companies to explore potential applications, and Altium is actively working on commercializing their technology. -

Q: How do the costs of tactile wood materials compare to traditional wood or other materials?

A: Due to the complex processing and technology involved, tactile wood materials like Woodoo and Altium are currently more expensive than traditional wood. However, as production scales up and processes are optimized, costs are expected to decrease, making these materials more accessible for a wider range of applications. -

Q: Are tactile wood materials suitable for outdoor use?

A: The suitability of tactile wood materials for outdoor use depends on the specific material and application. Woodoo, for example, has improved resistance to humidity and fire compared to natural wood, which could make it suitable for some outdoor applications. However, further research and testing are needed to fully assess the durability and performance of tactile wood materials in outdoor environments. -

Q: Can tactile wood materials be recycled or disposed of safely?

A: The recyclability and disposability of tactile wood materials depend on the specific components and processing methods used. Woodoo, for instance, uses bio-based polymers that are designed to be more environmentally friendly than traditional plastics. However, the recyclability of the material may be affected by the polymer-wood composite structure. Similarly, the electronic components in Altium’s surfaces may require special recycling or disposal procedures. As these materials continue to develop, it will be important to consider their end-of-life implications and develop appropriate recycling and disposal strategies. -

Q: What is the expected lifespan of tactile wood materials compared to traditional wood?

A: The lifespan of tactile wood materials is still being researched and will depend on factors such as the specific material composition, processing methods, and application environment. However, many tactile wood materials are designed to be more durable and resistant to wear than traditional wood. For example, Woodoo’s bio-polymer treatment makes the wood stronger and more resistant to humidity and fire, potentially extending its lifespan. As these materials continue to be developed and tested, more data on their long-term performance and durability will become available.

Conclusion

Tactile wood materials like Woodoo and Altium represent an exciting new frontier in material science and human-computer interaction. By combining the natural warmth and texture of wood with advanced technologies like bio-polymers and embedded electronics, these materials offer unique sensory experiences and enhanced functionality.

As research and development in this field continue, we can expect to see tactile wood materials being used in an ever-expanding range of applications, from luxury furniture and automotive interiors to interactive public installations and educational tools.

However, realizing the full potential of tactile wood materials will require overcoming challenges related to scalability, cost, durability, and maintenance. By addressing these challenges through ongoing research and innovation, the developers of tactile wood materials can help ensure their widespread adoption and long-term success.

Ultimately, the development of tactile wood materials like Woodoo and Altium represents a promising step towards a more sustainable, engaging, and multisensory future, where the boundaries between nature and technology are increasingly blurred. As these materials continue to evolve and mature, they have the potential to transform the way we interact with the world around us, bringing a new level of warmth, texture, and interactivity to our daily lives.

No responses yet