Introduction to PCB Electrical Testing

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices. They are used in a wide range of applications, from consumer electronics to aerospace and defense systems. PCBs are designed to provide reliable and efficient electrical connections between various components of an electronic device. However, to ensure that PCBs function as intended, they must undergo rigorous testing, including electrical testing.

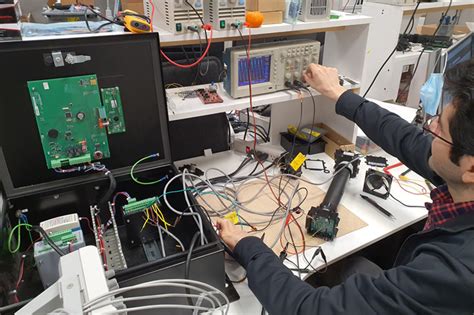

PCB electrical testing is a critical step in the manufacturing process that verifies the functionality and reliability of the PCB. It involves testing the PCB for shorts, opens, and other defects that can affect the performance of the electronic device. In this article, we will provide a comprehensive understanding of PCB electrical testing, including its importance, types of tests, and best practices.

Why is PCB Electrical Testing Important?

PCB electrical testing is essential for several reasons:

-

Quality Assurance: PCB electrical testing ensures that the PCB meets the required specifications and functions as intended. It helps identify defects and issues that may affect the performance of the electronic device.

-

Cost Savings: Identifying defects early in the manufacturing process can save significant costs associated with rework, repairs, and warranty claims. PCB electrical testing helps catch defects before the PCB is assembled into the final product.

-

Reliability: PCBs are used in critical applications where reliability is paramount. PCB electrical testing helps ensure that the PCB can withstand the expected operating conditions and perform reliably over its intended lifespan.

-

Compliance: Many industries have specific standards and regulations that PCBs must meet. PCB electrical testing helps ensure compliance with these standards and regulations.

Types of PCB Electrical Tests

There are several types of PCB electrical tests that can be performed, depending on the specific requirements of the PCB and the electronic device. Some of the most common types of PCB electrical tests include:

Continuity Test

A continuity test is used to verify that there is a continuous electrical path between two points on the PCB. This test is typically performed using a multimeter or a dedicated continuity tester. The test checks for opens, shorts, and high resistance connections that can affect the performance of the PCB.

Resistance Test

A resistance test is used to measure the resistance between two points on the PCB. This test is typically performed using a multimeter or a dedicated resistance tester. The test checks for shorts, opens, and incorrect resistance values that can affect the performance of the PCB.

Capacitance Test

A capacitance test is used to measure the capacitance of a capacitor on the PCB. This test is typically performed using a dedicated capacitance meter. The test checks for incorrect capacitance values, shorts, and opens that can affect the performance of the PCB.

Dielectric Withstanding Voltage (DWV) Test

A DWV test is used to verify the insulation resistance of the PCB. This test is typically performed using a high voltage tester. The test checks for leakage currents, arcing, and breakdown of the insulation that can affect the performance and safety of the PCB.

Insulation Resistance (IR) Test

An IR test is used to measure the resistance between two isolated conductors on the PCB. This test is typically performed using a high voltage tester. The test checks for leakage currents, shorts, and breakdown of the insulation that can affect the performance and safety of the PCB.

Hipot Test

A Hipot test is similar to a DWV test but is used to verify the insulation resistance of the PCB at a higher voltage. This test is typically performed using a high voltage tester. The test checks for leakage currents, arcing, and breakdown of the insulation that can affect the performance and safety of the PCB.

Flying Probe Test

A flying probe test is an automated test that uses moving probes to test the PCB. This test is typically used for low-volume production or prototype testing. The test checks for opens, shorts, and incorrect component values that can affect the performance of the PCB.

In-Circuit Test (ICT)

An ICT is an automated test that uses a bed of nails fixture to test the PCB. This test is typically used for high-volume production testing. The test checks for opens, shorts, incorrect component values, and functionality of the PCB.

Best Practices for PCB Electrical Testing

To ensure accurate and reliable PCB electrical testing, it is essential to follow best practices. Some of the best practices for PCB electrical testing include:

-

Test Early and Often: PCB electrical testing should be performed at various stages of the manufacturing process, from prototype to final production. Testing early and often helps identify defects and issues early in the process, reducing the cost and time required for rework and repairs.

-

Use Appropriate Test Equipment: PCB electrical testing requires specialized test equipment, such as multimeters, high voltage testers, and automated test equipment. It is essential to use appropriate test equipment that is calibrated and maintained regularly to ensure accurate and reliable test results.

-

Follow Test Procedures: PCB electrical testing should follow established test procedures and protocols. Test procedures should be documented and followed consistently to ensure accurate and repeatable test results.

-

Analyze Test Results: PCB electrical test results should be analyzed carefully to identify defects and issues. Root cause analysis should be performed to identify the underlying cause of the defect and implement corrective actions to prevent future occurrences.

-

Implement Quality Control Measures: Quality control measures should be implemented throughout the PCB manufacturing process to ensure consistent and reliable PCBs. This includes implementing statistical process control (SPC) techniques, such as control charts and process capability analysis, to monitor and control the manufacturing process.

Conclusion

PCB electrical testing is a critical step in the manufacturing process that ensures the functionality, reliability, and safety of PCBs. There are several types of PCB electrical tests, including continuity tests, resistance tests, capacitance tests, DWV tests, IR tests, Hipot tests, flying probe tests, and ICTs. To ensure accurate and reliable PCB electrical testing, it is essential to follow best practices, such as testing early and often, using appropriate test equipment, following test procedures, analyzing test results, and implementing quality control measures.

FAQ

-

What is PCB electrical testing?

PCB electrical testing is a process of verifying the functionality and reliability of a printed circuit board by testing for shorts, opens, and other defects that can affect the performance of the electronic device. -

Why is PCB electrical testing important?

PCB electrical testing is important for quality assurance, cost savings, reliability, and compliance with industry standards and regulations. -

What are the different types of PCB electrical tests?

The different types of PCB electrical tests include continuity tests, resistance tests, capacitance tests, DWV tests, IR tests, Hipot tests, flying probe tests, and ICTs. -

What are the best practices for PCB electrical testing?

The best practices for PCB electrical testing include testing early and often, using appropriate test equipment, following test procedures, analyzing test results, and implementing quality control measures. -

What equipment is used for PCB electrical testing?

PCB electrical testing requires specialized test equipment, such as multimeters, high voltage testers, and automated test equipment, that is calibrated and maintained regularly to ensure accurate and reliable test results.

| Test Type | Description | Purpose |

|---|---|---|

| Continuity Test | Verifies continuous electrical path between two points | Checks for opens, shorts, and high resistance connections |

| Resistance Test | Measures resistance between two points | Checks for shorts, opens, and incorrect resistance values |

| Capacitance Test | Measures capacitance of a capacitor | Checks for incorrect capacitance values, shorts, and opens |

| Dielectric Withstanding Voltage (DWV) Test | Verifies insulation resistance at high voltage | Checks for leakage currents, arcing, and breakdown of insulation |

| Insulation Resistance (IR) Test | Measures resistance between two isolated conductors | Checks for leakage currents, shorts, and breakdown of insulation |

| Hipot Test | Verifies insulation resistance at higher voltage than DWV test | Checks for leakage currents, arcing, and breakdown of insulation |

| Flying Probe Test | Automated test using moving probes | Checks for opens, shorts, and incorrect component values |

| In-Circuit Test (ICT) | Automated test using bed of nails fixture | Checks for opens, shorts, incorrect component values, and functionality |

No responses yet