Introduction to PCB Drilling

Printed Circuit Board (PCB) drilling is a critical process in the manufacturing of electronic devices. It involves creating holes in the PCB substrate to allow for the insertion of electronic components and the creation of electrical connections between layers. The drilling process is essential for ensuring the functionality, reliability, and durability of the final product.

In this comprehensive guide, we will delve into the intricacies of the PCB drilling process, covering topics such as drill bit selection, machine setup, drilling techniques, and quality control measures. By the end of this article, you will have a thorough understanding of the PCB drilling process and the best practices for achieving optimal results.

Types of PCB Drilling

There are two primary types of PCB drilling: mechanical drilling and laser drilling. Each method has its own advantages and disadvantages, and the choice between them depends on factors such as the required hole size, precision, and production volume.

Mechanical Drilling

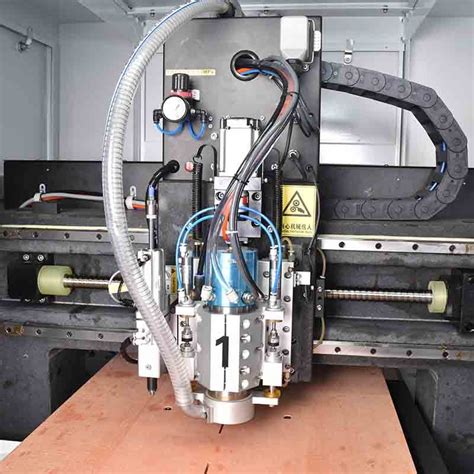

Mechanical drilling is the most common method for creating holes in PCBs. It involves using a rotating drill bit to physically remove material from the substrate. The process is relatively simple and cost-effective, making it suitable for a wide range of applications.

Advantages of mechanical drilling include:

– Wide range of drill bit sizes available

– Suitable for various PCB materials

– Cost-effective for low to medium production volumes

Disadvantages of mechanical drilling include:

– Limited precision compared to laser drilling

– Slower drilling speeds compared to laser drilling

– Potential for drill bit wear and breakage

Laser Drilling

Laser drilling is a more advanced method that uses a high-powered laser to vaporize the PCB material, creating precise holes without physical contact. This process is particularly useful for creating small, high-density holes that are difficult or impossible to achieve with mechanical drilling.

Advantages of laser drilling include:

– High precision and accuracy

– Ability to create very small holes (down to 25 microns)

– Faster drilling speeds compared to mechanical drilling

– No drill bit wear or breakage

Disadvantages of laser drilling include:

– Higher equipment costs compared to mechanical drilling

– Limited material compatibility (some materials may not be suitable for laser drilling)

– Potential for thermal damage to the PCB substrate

Drill Bit Selection

Choosing the right drill bit is crucial for achieving optimal results in PCB drilling. Drill bits come in a variety of sizes, materials, and coatings, each designed for specific applications and materials.

Drill Bit Materials

The most common drill bit materials used in PCB drilling are:

-

Carbide: Carbide drill bits are the most widely used in the industry due to their high wear resistance and durability. They are suitable for drilling a wide range of PCB materials, including FR-4, ceramic, and metal-clad substrates.

-

High-Speed Steel (HSS): HSS drill bits are less expensive than carbide bits but have lower wear resistance. They are best suited for drilling softer materials, such as single-sided PCBs or prototypes.

-

Diamond-Coated: Diamond-coated drill bits offer the highest wear resistance and are ideal for drilling abrasive materials, such as glass-reinforced epoxy or ceramic substrates. However, they are also the most expensive option.

Drill Bit Sizes

Drill bit sizes are typically expressed in either imperial (inches) or metric (millimeters) units. The most common sizes used in PCB drilling range from 0.2 mm to 6.35 mm (0.008″ to 0.25″). The choice of drill bit size depends on the component lead diameter and the desired hole tolerance.

Here is a table of common drill bit sizes and their applications:

| Drill Bit Size (mm) | Drill Bit Size (inches) | Application |

|---|---|---|

| 0.2 – 0.5 | 0.008″ – 0.020″ | Micro-vias, high-density interconnects |

| 0.6 – 1.0 | 0.024″ – 0.040″ | Standard through-holes, component leads |

| 1.1 – 2.0 | 0.043″ – 0.079″ | Power pins, connectors |

| 2.1 – 6.35 | 0.083″ – 0.250″ | Mounting holes, large connectors |

Drill Bit Coatings

Drill bit coatings can enhance the performance and durability of the drill bits, especially when working with abrasive or hard-to-drill materials. Some common coatings include:

-

Titanium Nitride (TiN): TiN coating improves the wear resistance and lubricity of the drill bit, reducing friction and heat generation during drilling.

-

Titanium Carbonitride (TiCN): TiCN coating offers even higher wear resistance than TiN, making it suitable for drilling harder materials or for extended production runs.

-

Diamond-Like Carbon (DLC): DLC coating provides a low-friction surface that helps to reduce heat generation and improve hole quality, particularly in high-speed drilling applications.

Machine Setup and Calibration

Proper machine setup and calibration are essential for ensuring accurate and consistent drilling results. The key steps in setting up a PCB drilling machine include:

-

Loading the drill program: The drill program contains the coordinates and parameters for each hole to be drilled. It is typically generated from the PCB design files using CAM (Computer-Aided Manufacturing) software.

-

Installing and aligning the drill bits: The selected drill bits must be installed in the machine’s spindles and aligned with the machine’s axes. This process may involve using a drill bit alignment tool or a camera system for automated alignment.

-

Setting the drill depth: The drill depth must be adjusted to ensure that the holes are drilled through the PCB substrate without damaging the backup material or the machine’s table.

-

Calibrating the machine’s axes: The machine’s X, Y, and Z axes must be calibrated to ensure accurate positioning of the drill bits. This process typically involves drilling test holes and measuring their positions using a coordinate measuring machine (CMM) or a visual inspection system.

-

Adjusting the spindle speed and feed rate: The spindle speed and feed rate must be optimized for the specific drill bit size, material, and PCB thickness to achieve the desired hole quality and minimize drill bit wear.

Drilling Techniques

Several drilling techniques can be employed to optimize the quality and efficiency of the PCB drilling process. These include:

Peck Drilling

Peck drilling involves repeatedly withdrawing and reinserting the drill bit during the drilling process to clear chips and debris from the hole. This technique helps to prevent drill bit breakage and improve hole quality, particularly when drilling deep holes or working with hard materials.

Stack Drilling

Stack drilling involves drilling multiple PCBs at once, with the boards stacked and secured together. This technique can significantly increase production efficiency but requires careful alignment and clamping to ensure consistent results.

Orbital Drilling

Orbital drilling is a specialized technique that involves rotating the drill bit in a small circular pattern while advancing it through the PCB. This method can help to reduce drill bit wear and improve hole quality, particularly when working with challenging materials or high aspect ratio holes.

Backup Material Selection

The choice of backup material is critical for supporting the PCB during drilling and preventing damage to the drill bits or the machine’s table. Common backup materials include:

-

Aluminum: Aluminum is a popular choice due to its durability and heat dissipation properties. It is suitable for a wide range of drilling applications.

-

Phenolic: Phenolic backup material is a cost-effective option that offers good stability and machinability. It is best suited for low to medium production volumes.

-

Fiberglass: Fiberglass backup material provides excellent support and drill bit protection, particularly when drilling high-density or hard-to-drill materials.

Quality Control and Inspection

Ensuring the quality of drilled holes is critical for the functionality and reliability of the final PCB Assembly. Quality control measures should be implemented throughout the drilling process, including:

-

Visual inspection: Drilled holes should be visually inspected for size, position, and quality using a microscope or automated inspection system.

-

Electrical testing: Continuity and insulation resistance tests can be performed to ensure that the drilled holes provide the required electrical connections without short circuits or leakage.

-

Cross-sectioning: In some cases, destructive testing may be necessary to evaluate the internal structure and quality of the drilled holes. This involves cutting the PCB and examining the hole cross-sections under a microscope.

-

Statistical process control (SPC): SPC techniques can be used to monitor the drilling process and identify trends or variations that may indicate potential quality issues. This involves collecting and analyzing data on hole sizes, positions, and other key parameters.

Best Practices for PCB Drilling

To achieve the best results in PCB drilling, consider the following best practices:

- Use high-quality drill bits appropriate for the specific application and material.

- Regularly inspect and replace drill bits to prevent wear and breakage.

- Optimize spindle speeds and feed rates for each drill bit size and material.

- Implement peck drilling for deep holes or challenging materials.

- Use appropriate backup materials to support the PCB and protect the drill bits.

- Regularly calibrate and maintain the drilling machine to ensure accurate and consistent results.

- Implement robust quality control measures, including visual inspection, electrical testing, and statistical process control.

Frequently Asked Questions (FAQ)

- What is the difference between mechanical and laser drilling for PCBs?

-

Mechanical drilling uses a rotating drill bit to physically remove material from the PCB, while laser drilling uses a high-powered laser to vaporize the material. Laser drilling offers higher precision and faster drilling speeds but is more expensive and has limited material compatibility compared to mechanical drilling.

-

How do I choose the right drill bit size for my PCB?

-

The choice of drill bit size depends on the component lead diameter and the desired hole tolerance. Refer to the manufacturer’s specifications or consult with your PCB fabrication partner to determine the appropriate drill bit size for your application.

-

What is peck drilling, and when should it be used?

-

Peck drilling involves repeatedly withdrawing and reinserting the drill bit during the drilling process to clear chips and debris from the hole. This technique is particularly useful for drilling deep holes or working with hard materials, as it helps to prevent drill bit breakage and improve hole quality.

-

How often should I replace my drill bits?

-

The frequency of drill bit replacement depends on factors such as the material being drilled, the drilling parameters, and the quality of the drill bits. Regular inspection and monitoring of drill bit wear is essential to determine when replacement is necessary. As a general rule, carbide drill bits should be replaced after drilling approximately 1,000 to 3,000 holes, while HSS drill bits may need to be replaced more frequently.

-

What are some common quality control methods for PCB drilling?

- Common quality control methods for PCB drilling include visual inspection, electrical testing, cross-sectioning, and statistical process control (SPC). Visual inspection is used to evaluate hole size, position, and quality, while electrical testing ensures proper connectivity and insulation. Cross-sectioning may be necessary for destructive testing and internal structure evaluation, and SPC helps monitor the drilling process and identify potential quality issues.

Conclusion

PCB drilling is a critical process in the manufacturing of electronic devices, requiring careful consideration of drill bit selection, machine setup, drilling techniques, and quality control measures. By understanding the intricacies of the drilling process and implementing best practices, manufacturers can ensure the production of high-quality, reliable PCBs that meet the demanding requirements of today’s electronics industry.

As technology continues to advance, the importance of precise and efficient PCB drilling will only continue to grow. By staying up-to-date with the latest drilling techniques, equipment, and best practices, manufacturers can remain competitive and deliver the high-quality products that their customers demand.

No responses yet