What is a CDI Ignition System?

A Capacitor Discharge Ignition (CDI) system is an electronic ignition system that uses capacitor discharge to create a high-voltage spark for igniting the air-fuel mixture in an internal combustion engine. CDI systems have become increasingly popular in various applications, including motorcycles, ATVs, outboard motors, and small engines, due to their reliability, efficiency, and performance benefits.

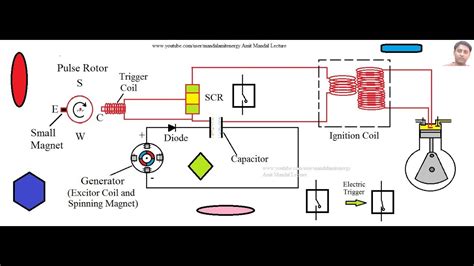

Key Components of a CDI System

A typical CDI system consists of the following main components:

- Charging Circuit

- Capacitor

- Triggering Circuit

- Ignition Coil

- Spark Plug

| Component | Function |

|---|---|

| Charging Circuit | Converts low-voltage DC from the battery or generator to high-voltage DC to charge the capacitor |

| Capacitor | Stores the high-voltage electrical energy until it is needed for the spark |

| Triggering Circuit | Controls the timing of the capacitor discharge based on the engine’s position and RPM |

| Ignition Coil | Transforms the high-voltage DC from the capacitor into an even higher voltage for the spark plug |

| Spark Plug | Receives the high-voltage current and generates the spark to ignite the air-fuel mixture |

How Does a CDI Ignition System Work?

The CDI ignition system operates through a series of steps:

-

The charging circuit converts the low-voltage DC from the battery or generator into high-voltage DC, typically around 200-400 volts.

-

The high-voltage DC charges the capacitor, which stores the electrical energy until it is needed for the spark.

-

The triggering circuit, which consists of a pickup coil and a control module, monitors the engine’s position and RPM. When the engine reaches the correct position for the spark, the triggering circuit sends a signal to the capacitor to discharge its stored energy.

-

The capacitor releases its stored energy in the form of a high-voltage pulse, which is sent to the ignition coil.

-

The ignition coil transforms the high-voltage pulse from the capacitor into an even higher voltage, typically around 20,000-40,000 volts.

-

The high-voltage current from the ignition coil is sent to the spark plug, which generates a spark to ignite the air-fuel mixture in the engine’s combustion chamber.

CDI Ignition Timing

One of the key aspects of a CDI ignition system is its precise timing control. The triggering circuit ensures that the spark occurs at the optimal moment for efficient combustion and maximum engine performance. The timing is determined by factors such as engine speed, load, and throttle position.

| Engine Speed (RPM) | Ignition Timing (Degrees Before TDC) |

|---|---|

| Idle | 5-10 |

| 1000 | 10-15 |

| 2000 | 15-20 |

| 3000 | 20-25 |

| 4000 | 25-30 |

| 5000+ | 30-35 |

Note: The above table provides general guidelines and may vary depending on the specific engine and CDI system.

Advantages of CDI Ignition Systems

CDI ignition systems offer several advantages over traditional points-based or inductive discharge ignition systems:

-

Reliability: CDI systems have fewer moving parts and are less susceptible to wear and tear, resulting in improved reliability and longer service life.

-

Efficiency: The high-voltage spark generated by a CDI system ensures more complete combustion of the air-fuel mixture, leading to improved fuel efficiency and reduced emissions.

-

Performance: CDI systems provide a stronger and more consistent spark, especially at high engine speeds, resulting in better engine performance and throttle response.

-

Maintenance: With no mechanical points to adjust or replace, CDI systems require less maintenance compared to traditional ignition systems.

-

Adaptability: CDI systems can be easily customized and programmed to suit specific engine requirements, allowing for optimal performance tuning.

Applications of CDI Ignition Systems

CDI ignition systems are widely used in various applications, including:

-

Motorcycles: Many modern motorcycles, especially high-performance and off-road models, utilize CDI ignition for its reliability and performance benefits.

-

ATVs and UTVs: All-terrain vehicles (ATVs) and utility task vehicles (UTVs) often employ CDI systems due to their ability to withstand harsh operating conditions and provide consistent ignition.

-

Outboard Motors: Marine outboard motors rely on CDI ignition to ensure reliable starting and smooth operation in challenging aquatic environments.

-

Small Engines: Lawnmowers, generators, and other small engines frequently use CDI systems for their simplicity, reliability, and ease of maintenance.

-

High-Performance Applications: CDI ignition is popular in racing and high-performance applications, where precise timing control and maximum spark energy are essential for optimal engine performance.

Troubleshooting CDI Ignition Systems

While CDI ignition systems are generally reliable, some issues may arise over time. Here are a few common problems and their potential solutions:

-

No Spark: If the engine fails to start and there is no spark at the spark plug, the problem could be a faulty capacitor, a damaged ignition coil, or a malfunctioning triggering circuit. Check the connections and components, and replace any faulty parts as necessary.

-

Intermittent Spark: An intermittent spark can be caused by loose connections, damaged wiring, or a failing capacitor. Inspect the wiring harness and connectors for any signs of damage or corrosion, and ensure that all connections are secure.

-

Timing Issues: If the engine runs poorly or experiences a loss of power, the CDI system’s timing may be off. This can be due to a faulty triggering circuit, incorrect installation, or damage to the pickup coil. Consult the manufacturer’s guidelines for proper timing settings and adjust as needed.

-

Overheating: In rare cases, a CDI system may overheat due to excessive voltage or a malfunctioning charging circuit. If the CDI unit becomes hot to the touch or emits a burning smell, shut off the engine immediately and investigate the cause of the problem.

If you encounter any issues with your CDI ignition system that you cannot resolve on your own, consult a qualified technician or the manufacturer for assistance.

Frequently Asked Questions (FAQ)

-

Q: Can I convert my points-based ignition system to a CDI system?

A: Yes, in most cases, it is possible to convert a points-based ignition system to a CDI system. However, it is essential to ensure that the CDI system is compatible with your specific engine and that the installation is performed correctly. -

Q: How often should I replace the capacitor in my CDI ignition system?

A: The lifespan of a capacitor in a CDI system varies depending on factors such as usage, operating conditions, and the quality of the component. As a general rule, it is recommended to replace the capacitor every 5-10 years or if you notice any signs of degraded performance. -

Q: Can I program my CDI ignition system for better performance?

A: Many modern CDI systems allow for customization and programming to optimize engine performance. However, it is essential to have a thorough understanding of the system and the engine’s requirements before making any changes. Consult with a qualified technician or the manufacturer for guidance on programming your specific CDI system. -

Q: Are CDI ignition systems more expensive than traditional ignition systems?

A: Initially, CDI ignition systems may be more expensive than points-based or inductive discharge systems due to their advanced electronic components. However, the long-term benefits of improved reliability, performance, and reduced maintenance costs often outweigh the initial investment. -

Q: Can I install a CDI ignition system on my vintage motorcycle?

A: Yes, it is possible to install a CDI ignition system on a vintage motorcycle. Many aftermarket CDI systems are designed specifically for classic bikes, offering improved performance and reliability while maintaining the vehicle’s original appearance. However, it is essential to choose a system that is compatible with your specific make and model and to follow the installation instructions carefully.

In conclusion, CDI ignition systems offer numerous benefits over traditional ignition systems, including improved reliability, efficiency, performance, and reduced maintenance. With their widespread applications in motorcycles, ATVs, outboard motors, and small engines, CDI systems have proven to be a great choice for a wide range of ignition needs. By understanding the components, operation, and troubleshooting of CDI systems, users can ensure optimal performance and longevity of their engines.

No responses yet