Introduction to Carbon Nanotube PCBs

Carbon nanotubes (CNTs) have emerged as a revolutionary material in the field of printed circuit boards (PCBs). With their exceptional electrical, thermal, and mechanical properties, CNTs have the potential to transform the way PCBs are designed and manufactured. This article delves into the world of carbon nanotube PCBs, exploring their unique characteristics, advantages, and potential applications.

What are Carbon Nanotubes?

Carbon nanotubes are cylindrical structures composed of carbon atoms arranged in a hexagonal lattice. They can be visualized as a sheet of graphene rolled into a seamless tube. CNTs exist in two main forms: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). SWCNTs consist of a single layer of graphene, while MWCNTs comprise multiple concentric layers.

Properties of Carbon Nanotubes

Carbon nanotubes exhibit remarkable properties that make them highly desirable for various applications, including PCBs:

-

Electrical Conductivity: CNTs have excellent electrical conductivity, surpassing that of copper. They can carry high current densities without experiencing electromigration, making them suitable for high-speed and high-frequency applications.

-

Thermal Conductivity: CNTs possess exceptional thermal conductivity, enabling efficient heat dissipation in PCBs. This property is crucial for managing thermal issues in high-power electronics.

-

Mechanical Strength: Carbon nanotubes have extraordinary mechanical strength, with a tensile strength up to 100 times greater than steel. This strength enables the creation of robust and durable PCBs.

-

Lightweight: CNTs are incredibly lightweight compared to traditional PCB materials, allowing for the design of lighter and more compact electronic devices.

Advantages of Carbon Nanotube PCBs

The incorporation of carbon nanotubes in PCBs offers several advantages over conventional PCB materials:

Enhanced Signal Integrity

Carbon nanotube PCBs exhibit improved signal integrity due to their low dielectric constant and low loss tangent. These properties minimize signal distortion and attenuation, enabling faster signal propagation and reduced crosstalk. This enhancement is particularly beneficial for high-speed digital circuits and high-frequency applications.

Improved Thermal Management

The exceptional thermal conductivity of CNTs allows for efficient heat dissipation in PCBs. By integrating carbon nanotubes into the PCB substrate or using them as thermal vias, heat generated by electronic components can be effectively transferred away from critical areas. This improved thermal management helps prevent overheating and enhances the reliability and longevity of electronic devices.

Increased Durability and Reliability

The mechanical strength of carbon nanotubes translates into more durable and reliable PCBs. CNT-reinforced PCBs can withstand higher mechanical stresses, vibrations, and impacts compared to traditional PCBs. This increased durability is particularly advantageous in applications where the PCBs are subjected to harsh environmental conditions or frequent handling.

Miniaturization and Weight Reduction

The use of carbon nanotubes in PCBs enables the miniaturization of electronic devices. With their excellent electrical and thermal properties, CNTs allow for the design of thinner and more compact PCBs without compromising performance. Additionally, the lightweight nature of CNTs contributes to overall weight reduction, which is crucial in applications such as aerospace and portable electronics.

Manufacturing Processes for Carbon Nanotube PCBs

The incorporation of carbon nanotubes into PCBs requires specialized manufacturing processes. Here are some common methods used in the production of carbon nanotube PCBs:

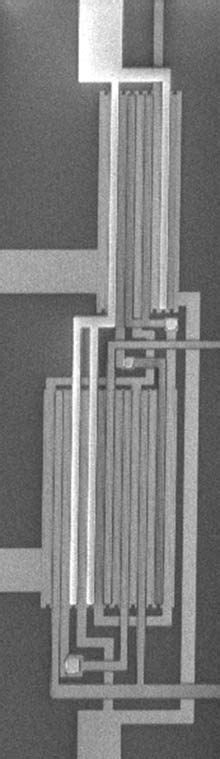

Chemical Vapor Deposition (CVD)

Chemical vapor deposition is a widely used technique for growing carbon nanotubes directly on PCB Substrates. In this process, a catalyst material is deposited on the substrate, and the substrate is then exposed to a carbon-containing gas at high temperatures. The catalyst particles facilitate the growth of carbon nanotubes on the substrate surface.

Inkjet Printing

Inkjet printing is a promising method for depositing carbon nanotubes onto PCB substrates. In this process, a CNT-based ink is precisely deposited onto the desired areas of the PCB using an inkjet printer. This technique allows for the selective placement of CNTs and enables the creation of intricate patterns and circuits.

Screen Printing

Screen printing involves the use of a stencil or screen to transfer a CNT-based paste onto the PCB substrate. The paste is forced through the openings of the screen using a squeegee, depositing the carbon nanotubes onto the desired areas. This method is suitable for large-scale production and can achieve good uniformity and thickness control.

Embedding and Lamination

Carbon nanotubes can also be embedded into the PCB substrate during the lamination process. In this approach, CNTs are dispersed in the prepreg material, which is then laminated with the PCB Layers under high pressure and temperature. This method ensures a uniform distribution of CNTs throughout the PCB substrate.

Potential Applications of Carbon Nanotube PCBs

Carbon nanotube PCBs have the potential to revolutionize various industries and applications. Some notable areas where CNT-based PCBs can make a significant impact include:

High-Speed Electronics

The excellent electrical properties of carbon nanotubes make them ideal for high-speed electronic applications. CNT-based PCBs can support faster signal transmission and reduce signal integrity issues, enabling the development of high-performance digital circuits, such as high-speed data communication systems and high-frequency radar.

Aerospace and Defense

The lightweight and durable nature of carbon nanotube PCBs is particularly advantageous in the aerospace and defense sectors. CNT-based PCBs can withstand harsh environmental conditions, including extreme temperatures, vibrations, and shocks. They can be used in avionics systems, satellite communication devices, and military equipment, where reliability and weight reduction are critical.

Automotive Electronics

Carbon nanotube PCBs can significantly contribute to the advancement of automotive electronics. With their enhanced thermal management capabilities and durability, CNT-based PCBs can handle the demanding requirements of automotive applications, such as engine control units, power electronics, and advanced driver assistance systems (ADAS).

Internet of Things (IoT) Devices

The miniaturization and weight reduction capabilities of carbon nanotube PCBs are highly relevant for IoT devices. CNT-based PCBs can enable the development of smaller, lighter, and more energy-efficient IoT sensors and devices. This is particularly important in applications such as Wearable Technology, smart home devices, and Industrial IoT sensors.

Challenges and Future Prospects

While carbon nanotube PCBs offer numerous advantages, there are still some challenges to overcome for their widespread adoption:

Cost Considerations

The production of carbon nanotubes and their incorporation into PCBs is currently more expensive compared to traditional PCB materials. Further research and development efforts are needed to optimize manufacturing processes and reduce costs to make CNT-based PCBs more economically viable.

Standardization and Reliability Testing

As carbon nanotube PCBs are a relatively new technology, there is a need for standardization and comprehensive reliability testing. Establishing industry standards and conducting extensive testing will help ensure the consistency, reliability, and long-term performance of CNT-based PCBs.

Integration with Existing Manufacturing Infrastructure

Integrating carbon nanotube PCBs into existing manufacturing infrastructure may require modifications and upgrades. PCB manufacturers will need to adapt their processes and equipment to accommodate the unique properties and handling requirements of CNTs.

Despite these challenges, the future prospects for carbon nanotube PCBs are promising. With ongoing research and development efforts, it is expected that the manufacturing processes will become more efficient and cost-effective over time. As the technology matures and gains wider acceptance, carbon nanotube PCBs have the potential to transform the electronics industry, enabling the development of faster, smaller, and more reliable electronic devices.

Frequently Asked Questions (FAQ)

-

What are the main advantages of using carbon nanotubes in PCBs?

Carbon nanotubes offer several advantages in PCBs, including enhanced signal integrity, improved thermal management, increased durability and reliability, and the potential for miniaturization and weight reduction. -

How do carbon nanotubes improve signal integrity in PCBs?

Carbon nanotubes have a low dielectric constant and low loss tangent, which minimizes signal distortion and attenuation. This enables faster signal propagation and reduces crosstalk, making CNT-based PCBs suitable for high-speed and high-frequency applications. -

Are carbon nanotube PCBs more expensive than traditional PCBs?

Currently, the production of carbon nanotube PCBs is more expensive compared to traditional PCBs due to the cost of carbon nanotubes and the specialized manufacturing processes involved. However, as research and development efforts progress, it is expected that the costs will decrease over time. -

Can carbon nanotube PCBs be used in harsh environmental conditions?

Yes, carbon nanotube PCBs are well-suited for harsh environmental conditions. Their exceptional mechanical strength and durability enable them to withstand higher mechanical stresses, vibrations, and impacts compared to traditional PCBs. This makes them particularly advantageous in applications such as aerospace and defense. -

What are the potential applications of carbon nanotube PCBs?

Carbon nanotube PCBs have potential applications in various industries, including high-speed electronics, aerospace and defense, automotive electronics, and Internet of Things (IoT) devices. They can enable the development of faster, smaller, and more reliable electronic devices in these sectors.

| Property | Carbon Nanotube PCBs | Traditional PCBs |

|---|---|---|

| Electrical Conductivity | Excellent | Good |

| Thermal Conductivity | Exceptional | Moderate |

| Mechanical Strength | Extraordinary | Good |

| Weight | Lightweight | Heavier |

| Signal Integrity | Enhanced | Good |

| Thermal Management | Improved | Moderate |

| Durability | High | Moderate |

| Miniaturization Potential | High | Limited |

Conclusion

Carbon nanotube PCBs represent a significant advancement in printed circuit board technology. With their exceptional electrical, thermal, and mechanical properties, CNT-based PCBs offer numerous advantages over traditional PCBs. They have the potential to revolutionize various industries, including high-speed electronics, aerospace and defense, automotive electronics, and IoT devices.

While there are challenges to overcome, such as cost considerations and standardization, the future prospects for carbon nanotube PCBs are promising. As research and development efforts continue, it is expected that the manufacturing processes will become more efficient and cost-effective, paving the way for widespread adoption.

The integration of carbon nanotubes into PCBs opens up new possibilities for the design and performance of electronic devices. With their ability to enhance signal integrity, improve thermal management, increase durability, and enable miniaturization, carbon nanotube PCBs are poised to shape the future of the electronics industry.

As technology advances and the demand for faster, smaller, and more reliable electronic devices grows, carbon nanotube PCBs are likely to play a crucial role in meeting these requirements. The continued exploration and development of CNT-based PCBs will undoubtedly lead to exciting innovations and Breakthroughs in the field of electronics.

No responses yet