Understanding PCB Boundary Selection

PCB (Printed Circuit Board) design involves placing various components and objects within a defined boundary. The PCB boundary represents the physical limits of the board, and all components must be placed within this boundary for proper manufacturing and functionality. However, sometimes users may encounter difficulties when trying to select an object that is located far from the PCB boundary. This article will explore the reasons behind this issue and provide solutions to overcome it.

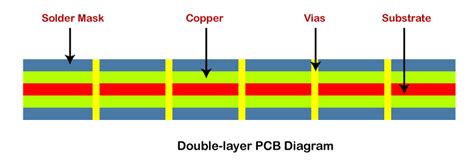

What is PCB Boundary?

A PCB boundary is a virtual border that defines the physical limits of a printed circuit board. It is a crucial aspect of PCB design as it ensures that all components and objects are placed within the manufacturable area of the board. The PCB boundary is typically represented by a rectangle or a polygon, depending on the shape of the board.

Why is PCB Boundary Selection Important?

Proper PCB boundary selection is essential for several reasons:

-

Manufacturing Constraints: PCB manufacturers have specific requirements regarding the placement of components and objects within the PCB boundary. Violating these constraints can lead to manufacturing issues and delays.

-

Functionality: Components placed outside the PCB boundary may not function correctly or may not be connected to the rest of the circuit properly.

-

Design Rule Checking (DRC): PCB design software uses the PCB boundary to perform design rule checks, ensuring that the design adheres to the specified manufacturing constraints and guidelines.

Common Issues with PCB Boundary Selection

-

Incorrect Boundary Definition: If the PCB boundary is not defined correctly, it can lead to difficulties in selecting objects that are located far from the boundary. This can happen if the boundary is too small or not properly aligned with the board outline.

-

Object Placement Outside Boundary: If an object is placed outside the PCB boundary, it may not be selectable using the standard selection tools. This can occur if the object was manually placed or if the boundary was modified after the object was placed.

-

Incorrect Layer Assignment: Objects assigned to the wrong layer may appear to be outside the PCB boundary, making them difficult to select. This can happen if the object’s layer is not visible or if it is assigned to a non-standard layer.

Solutions for Selecting Objects Far From PCB Boundary

- Verify PCB Boundary Definition:

- Check if the PCB boundary is correctly defined and aligned with the board outline.

- Ensure that the boundary encompasses all the necessary components and objects.

-

If the boundary is incorrect, modify it to match the desired board outline.

-

Use Advanced Selection Methods:

- Most PCB design software offers advanced selection methods to select objects that are difficult to reach with standard selection tools.

- These methods may include:

- Selection by object type: Select all objects of a specific type, such as all components or all traces.

- Selection by layer: Select all objects on a specific layer or a range of layers.

- Selection by net: Select all objects connected to a specific net or signal.

-

Experiment with different selection methods to find the one that works best for your specific case.

-

Temporarily Modify Layer Visibility:

- If the object is assigned to a layer that is not visible, make that layer visible temporarily.

- This will allow you to select the object using the standard selection tools.

-

After selecting the object, you can hide the layer again if needed.

-

Move Objects Within Boundary:

- If an object is placed outside the PCB boundary, move it within the boundary using the design software’s move tools.

- Ensure that the object is properly aligned and connected to the rest of the circuit.

-

Perform a design rule check (DRC) to verify that the modified placement meets the manufacturing constraints.

-

Seek Assistance from the PCB Design Software Support:

- If none of the above solutions work, reach out to the support team of your PCB design software.

- Provide them with details about your specific issue, including screenshots and design files if necessary.

- They may have additional suggestions or be able to identify any software-specific issues that are preventing object selection.

FAQs

-

Q: What happens if I place a component outside the PCB boundary?

A: Placing a component outside the PCB boundary can lead to manufacturing issues and functionality problems. The component may not be properly connected to the rest of the circuit, and it may violate the manufacturing constraints set by the PCB fabricator. It is essential to keep all components within the defined PCB boundary to ensure proper manufacturing and functionality. -

Q: Can I modify the PCB boundary after placing components?

A: Yes, you can modify the PCB boundary after placing components. However, be cautious when doing so, as modifying the boundary may cause some components to fall outside the new boundary. Always review the placement of components after modifying the boundary and make necessary adjustments to ensure that all components are within the updated boundary. -

Q: What should I do if I can’t select an object using the standard selection tools?

A: If you are unable to select an object using the standard selection tools, try using advanced selection methods offered by your PCB design software. These methods may include selection by object type, layer, or net. Experiment with different selection methods to find the one that works for your specific case. If the object is assigned to a hidden layer, make that layer visible temporarily to select the object. -

Q: How can I prevent objects from being placed outside the PCB boundary?

A: To prevent objects from being placed outside the PCB boundary, ensure that the boundary is correctly defined and aligned with the board outline. Most PCB design software has built-in design rule checks (DRC) that can alert you if any objects violate the boundary constraints. Running DRC regularly can help identify and fix any boundary-related issues early in the design process. -

Q: What if I still can’t select an object after trying all the solutions?

A: If you have tried all the suggested solutions and still cannot select an object, reach out to the support team of your PCB design software. Provide them with detailed information about your issue, including screenshots and design files if necessary. They may have additional suggestions or be able to identify any software-specific issues preventing object selection.

| Solution | Description |

|---|---|

| Verify PCB Boundary Definition | Ensure the PCB boundary is correctly defined and aligned |

| Use Advanced Selection Methods | Utilize selection by object type, layer, or net for difficult objects |

| Temporarily Modify Layer Visibility | Make hidden layers visible to select objects assigned to those layers |

| Move Objects Within Boundary | Relocate objects placed outside the boundary to within the limits |

| Seek Software Support Assistance | Contact the PCB design software support team for further guidance |

By understanding the importance of PCB boundary selection and following the solutions outlined in this article, you can overcome the challenges of selecting objects that are located far from the PCB boundary. Always ensure that your design adheres to the manufacturing constraints and guidelines to avoid any issues during the fabrication process.

No responses yet