Introduction to Altium Bill of Materials

In the world of electronic design, creating an accurate and comprehensive Bill of Materials (BOM) is crucial for ensuring the success of your project. Altium, a leading PCB design software, offers a powerful tool called ActiveBOM that simplifies the process of generating and managing BOMs. In this article, we’ll explore the features and benefits of ActiveBOM and how it can streamline your design workflow.

What is a Bill of Materials?

A Bill of Materials (BOM) is a detailed list of all the components, parts, and materials required to manufacture a product. It serves as a critical document for project management, procurement, and production. A well-organized BOM helps ensure that all necessary components are accounted for, ordered, and available when needed.

Key Elements of a Bill of Materials

A typical BOM includes the following information:

- Part Number: A unique identifier for each component.

- Description: A brief description of the component, including its function and characteristics.

- Quantity: The number of each component required for the project.

- Reference Designator: The reference designator assigned to each component on the schematic and PCB layout.

- Manufacturer: The name of the component manufacturer.

- Manufacturer Part Number: The manufacturer’s unique identifier for the component.

Challenges in Creating and Managing BOMs

Creating and managing BOMs can be a time-consuming and error-prone process, especially for complex designs with numerous components. Some common challenges include:

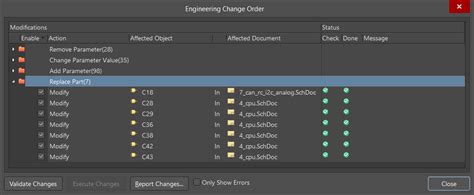

- Ensuring accuracy and consistency across multiple design revisions.

- Keeping track of component changes and updates.

- Collaborating with team members and stakeholders.

- Integrating BOM data with other tools and systems, such as ERP or PLM software.

Introducing Altium ActiveBOM

Altium ActiveBOM is a powerful tool that simplifies the process of creating, managing, and sharing BOMs within the Altium Designer environment. It offers a range of features and benefits that address the challenges associated with traditional BOM management.

Key Features of ActiveBOM

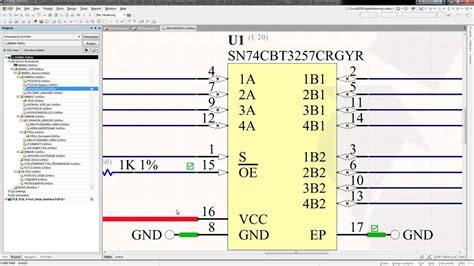

- Automated BOM Generation: ActiveBOM automatically generates a BOM based on the components used in your schematic and PCB design.

- Real-time Synchronization: Any changes made to the design are instantly reflected in the BOM, ensuring accuracy and consistency.

- Customizable Templates: ActiveBOM allows you to create and customize BOM templates to suit your specific requirements.

- Integration with Supplier Data: ActiveBOM can pull component information directly from supplier databases, reducing manual data entry and errors.

- Collaboration and Sharing: ActiveBOM enables easy collaboration and sharing of BOM data with team members and stakeholders.

Benefits of Using ActiveBOM

- Improved Accuracy: Automated BOM generation and real-time synchronization minimize the risk of errors and inconsistencies.

- Time Savings: ActiveBOM streamlines the BOM creation process, saving valuable time and effort.

- Enhanced Collaboration: Easy sharing and collaboration features facilitate effective communication and decision-making.

- Increased Efficiency: Integration with supplier data and other tools optimizes the procurement and manufacturing processes.

Getting Started with ActiveBOM

To start using ActiveBOM in your Altium Designer projects, follow these steps:

- Ensure that you have the latest version of Altium Designer installed.

- Open your project in Altium Designer.

- Navigate to the “Tools” menu and select “ActiveBOM.”

- Configure your ActiveBOM settings, including template selection and supplier data integration.

- Generate your BOM by clicking the “Generate” button.

ActiveBOM Configuration Options

ActiveBOM offers several configuration options to customize your BOM generation:

- Template Selection: Choose from pre-defined templates or create your own to match your company’s standards.

- Field Mapping: Map component properties to specific BOM fields for accurate data population.

- Supplier Data Integration: Configure ActiveBOM to pull component information from supplier databases, such as Digi-Key or Mouser.

- Output Format: Select the desired output format for your BOM, such as Excel, CSV, or PDF.

ActiveBOM Best Practices

To maximize the benefits of ActiveBOM, consider the following best practices:

- Establish Naming Conventions: Use consistent naming conventions for components, reference designators, and other BOM fields to ensure clarity and ease of use.

- Regularly Update Supplier Data: Keep your supplier data up to date to ensure accurate component information and pricing.

- Collaborate with Stakeholders: Involve relevant stakeholders, such as procurement and manufacturing teams, in the BOM review and approval process.

- Version Control: Maintain version control of your BOMs to track changes and revisions over time.

Common ActiveBOM Use Cases

ActiveBOM can be applied to various use cases across different industries:

- Electronics Manufacturing: Generate accurate BOMs for PCB assembly and production.

- Aerospace and Defense: Ensure compliance with strict documentation requirements and traceability.

- Medical Devices: Maintain detailed BOMs for regulatory compliance and quality control.

- Automotive: Streamline BOM management for complex vehicle electronics systems.

Integrating ActiveBOM with Other Tools

ActiveBOM can be integrated with other tools and systems to further streamline your design and manufacturing processes:

- ERP Systems: Export BOM data to your enterprise resource planning (ERP) system for inventory management and procurement.

- PLM Software: Integrate ActiveBOM with product lifecycle management (PLM) software to manage BOM revisions and changes.

- Manufacturing Execution Systems (MES): Feed BOM data into your MES to optimize production planning and scheduling.

Case Study: XYZ Electronics

XYZ Electronics, a leading manufacturer of consumer electronics, implemented Altium ActiveBOM to streamline their BOM management process. By automating BOM generation and integrating with their ERP system, they achieved the following results:

- Reduced BOM creation time by 50%

- Improved BOM accuracy by 95%

- Decreased component ordering errors by 80%

- Shortened time-to-market by 25%

Frequently Asked Questions (FAQ)

-

Can ActiveBOM handle Multi-Level BOMs?

Yes, ActiveBOM supports the creation and management of multi-level BOMs, allowing you to capture the hierarchical structure of your product. -

Is ActiveBOM compatible with other PCB design software?

ActiveBOM is a feature specific to Altium Designer and may not be directly compatible with other PCB design software. However, you can export BOM data from ActiveBOM in standard formats like Excel or CSV for use in other systems. -

Can I customize the BOM template in ActiveBOM?

Yes, ActiveBOM allows you to create and customize BOM templates to match your company’s specific requirements and standards. -

How does ActiveBOM handle component variations and alternates?

ActiveBOM supports the definition of component variations and alternates, allowing you to specify alternative parts that can be used in place of the primary component. -

Can ActiveBOM generate BOMs for multiple projects simultaneously?

Yes, ActiveBOM can generate BOMs for multiple projects at once, saving time and effort when working on complex designs or multiple projects concurrently.

Conclusion

Altium ActiveBOM is a powerful tool that simplifies the process of creating, managing, and sharing BOMs in the Altium Designer environment. By automating BOM generation, ensuring real-time synchronization, and offering customizable templates, ActiveBOM addresses the challenges associated with traditional BOM management.

Implementing ActiveBOM in your design workflow can lead to improved accuracy, time savings, enhanced collaboration, and increased efficiency. By following best practices and integrating ActiveBOM with other tools and systems, you can further optimize your design and manufacturing processes.

As demonstrated in the case study of XYZ Electronics, adopting ActiveBOM can result in significant improvements in BOM accuracy, time-to-market, and overall productivity.

To start leveraging the benefits of ActiveBOM, ensure that you have the latest version of Altium Designer installed and follow the steps outlined in this article to configure and generate your BOMs.

By embracing the power of ActiveBOM, you can streamline your BOM management process, reduce errors, and focus on what matters most – designing innovative and high-quality electronic products.

No responses yet