What are PCB Gold Fingers?

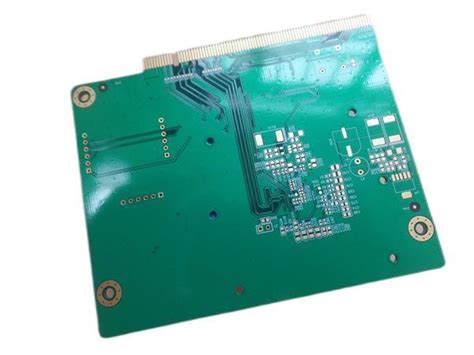

PCB gold fingers, also known as edge connectors or contact fingers, are the exposed conductive traces found on the edge of a printed circuit board (PCB). These traces are plated with a thin layer of gold, which provides excellent conductivity and resistance to corrosion. The gold plating ensures a reliable electrical connection when the PCB is inserted into a corresponding connector or slot.

Key Features of PCB Gold Fingers

- Gold plating: The traces are plated with a layer of gold, typically ranging from 2 to 30 microinches in thickness.

- Precision design: Gold fingers are designed with precise dimensions and spacing to ensure proper mating with connectors.

- Durability: The gold plating provides excellent wear resistance, allowing for repeated insertions and removals.

Applications of PCB Gold Fingers

PCB gold fingers find applications in various industries and devices. Some common examples include:

- Computer hardware: PCB gold fingers are used in memory modules, graphics cards, and other expansion cards.

- Consumer electronics: Many devices, such as smartphones, tablets, and gaming consoles, utilize PCB gold fingers for connecting components like displays and storage.

- Industrial equipment: Gold fingers are used in industrial control systems, data acquisition modules, and other specialized equipment.

- Medical devices: PCB gold fingers are found in medical equipment, such as patient monitors and diagnostic tools.

Manufacturing Process of PCB Gold Fingers

The manufacturing process of PCB gold fingers involves several steps to ensure high quality and reliability:

- PCB design: The PCB layout is designed with the gold finger traces incorporated into the edge of the board.

- PCB fabrication: The PCB is manufactured using standard processes, such as etching and drilling.

- Nickel plating: A layer of nickel is plated onto the exposed traces to provide a barrier between the copper and the gold plating.

- Gold plating: The nickel-plated traces are then plated with a thin layer of gold using electroplating or immersion plating techniques.

- Finishing: The PCB undergoes final finishing processes, such as solder mask application and silkscreen printing.

Comparison of Gold Plating Methods

| Method | Thickness | Advantages | Disadvantages |

|---|---|---|---|

| Electroplating | 2-30 microinches | Precise control, good adhesion | Higher cost, longer process time |

| Immersion plating | 1-5 microinches | Lower cost, faster process | Limited thickness, potential for porosity |

Design Considerations for PCB Gold Fingers

When designing PCBs with gold fingers, several factors must be considered to ensure optimal performance and reliability:

- Trace width and spacing: The width and spacing of the gold finger traces should be designed according to the specific connector requirements.

- Impedance control: Proper impedance matching is crucial to minimize signal reflections and ensure integrity.

- Mechanical stability: The PCB design should account for the mechanical stresses encountered during insertion and removal of the gold fingers.

- Solder mask clearance: Adequate solder mask clearance should be provided around the gold fingers to prevent solder bridging during assembly.

Testing and Quality Control

To ensure the quality and reliability of PCB gold fingers, various tests and inspections are conducted:

- Visual inspection: The gold fingers are visually inspected for defects, such as scratches, contamination, or uneven plating.

- Thickness measurement: The gold plating thickness is measured using X-ray fluorescence (XRF) or other methods to ensure compliance with specifications.

- Continuity testing: Electrical continuity between the gold fingers and the corresponding PCB traces is verified.

- Insertion/extraction testing: The mechanical durability of the gold fingers is tested by subjecting them to repeated insertion and extraction cycles.

Troubleshooting Common Issues

Despite careful design and manufacturing, issues may arise with PCB gold fingers. Some common problems and their solutions include:

- Poor contact: If the gold fingers fail to make proper contact with the connector, cleaning the contacts and ensuring proper alignment can resolve the issue.

- Wear and tear: Excessive wear on the gold fingers can lead to connectivity problems. Replacing the affected PCB or connector may be necessary.

- Contamination: Dirt, dust, or other contaminants on the gold fingers can hinder electrical contact. Regular cleaning using appropriate methods can prevent this issue.

Future Trends in PCB Gold Fingers

As technology advances, PCB gold fingers are evolving to meet new challenges and requirements:

- High-speed applications: With increasing data rates, gold finger designs are being optimized for high-speed signal integrity.

- Miniaturization: As devices become smaller, PCB gold fingers are being designed with finer pitches and reduced dimensions.

- Alternative materials: Research is ongoing to explore alternative plating materials that offer similar or better performance compared to gold.

Frequently Asked Questions (FAQ)

-

Q: What is the purpose of the nickel layer beneath the gold plating?

A: The nickel layer acts as a barrier between the copper traces and the gold plating. It prevents the formation of intermetallic compounds and enhances the adhesion of the gold plating. -

Q: Can PCB gold fingers be repaired if damaged?

A: In most cases, damaged gold fingers cannot be easily repaired. Depending on the extent of the damage, the affected PCB may need to be replaced. -

Q: Are there any alternatives to gold plating for PCB fingers?

A: While gold is the most common choice due to its excellent conductivity and corrosion resistance, other materials such as palladium or silver can be used in certain applications. -

Q: How does the thickness of the gold plating affect the performance of PCB gold fingers?

A: Thicker gold plating generally provides better wear resistance and durability. However, excessive thickness can lead to issues such as difficulty in soldering or increased cost. -

Q: Can PCB gold fingers be customized for specific applications?

A: Yes, PCB gold fingers can be designed and manufactured to meet specific requirements, such as unique connector configurations or environmental conditions.

Conclusion

PCB gold fingers play a vital role in ensuring reliable and efficient electrical connections in a wide range of electronic devices. By understanding the fundamentals of PCB gold fingers, including their design, manufacturing, and testing considerations, engineers and manufacturers can create high-quality products that meet the demands of modern applications. As technology continues to evolve, PCB gold fingers will undoubtedly remain an essential component in the world of electronics.

No responses yet