What is an Air Conditioner PCB Board?

An air conditioner PCB board is a complex electronic circuit that serves as the brain of the air conditioning system. It consists of various components such as microcontrollers, sensors, relays, and capacitors, all working together to regulate the cooling process, maintain the desired temperature, and ensure the overall efficiency of the air conditioner.

Key Components of an AC PCB Board

- Microcontroller:

- The microcontroller is the central processing unit of the PCB board.

-

It receives inputs from sensors and user settings, processes the information, and sends control signals to other components.

-

Temperature Sensors:

- Temperature sensors, such as thermistors or RTDs, measure the ambient temperature and provide feedback to the microcontroller.

-

They help maintain the desired temperature by triggering the compressor and fan to start or stop based on the temperature readings.

-

Relays:

- Relays are electromagnetic switches that control the power supply to various components of the air conditioner.

-

They are responsible for turning the compressor, fan, and other parts on or off based on the microcontroller’s commands.

-

Capacitors:

- Capacitors store electrical energy and help stabilize the power supply to the PCB board.

-

They also filter out electrical noise and protect the circuit from voltage fluctuations.

-

Fuse:

- The fuse is a safety device that protects the PCB board and other components from excessive current.

- If the current exceeds a certain threshold, the fuse melts, breaking the circuit and preventing damage to the system.

Functions of an AC PCB Board

The AC PCB board performs several critical functions to ensure the proper operation of the air conditioner:

- Temperature Control:

- The PCB board constantly monitors the ambient temperature using sensors.

-

It compares the measured temperature with the user-set temperature and adjusts the compressor and fan accordingly to maintain the desired temperature.

-

Fan Speed Control:

- The PCB board regulates the speed of the indoor and outdoor fans based on the cooling requirements.

-

It can adjust the fan speed to optimize air circulation and maintain a comfortable environment.

-

Compressor Control:

- The compressor is responsible for compressing the refrigerant and circulating it through the air conditioner.

-

The PCB board controls the compressor’s operation, turning it on or off based on the cooling demand and temperature settings.

-

Error Detection and Protection:

- The PCB board continuously monitors various parameters such as voltage, current, and temperature.

- If any abnormalities or faults are detected, the board can trigger safety mechanisms, such as shutting down the compressor or displaying error codes, to protect the air conditioner from damage.

Common Problems with AC PCB Boards

Like any electronic component, AC PCB boards can experience issues that affect the performance and reliability of the air conditioner. Some common problems include:

- Capacitor Failure:

- Capacitors are prone to degradation over time, especially in high-temperature environments.

-

A failed capacitor can cause the air conditioner to malfunction, leading to reduced cooling capacity or complete system failure.

-

Relay Malfunction:

- Relays can become stuck or fail to switch due to wear and tear or electrical issues.

-

A malfunctioning relay can prevent the compressor or fan from turning on, resulting in inadequate cooling.

-

Sensor Failure:

- Temperature sensors can become damaged or provide inaccurate readings.

-

Faulty sensors can lead to incorrect temperature control, causing the air conditioner to over-cool or under-cool the room.

-

Microcontroller Issues:

- The microcontroller can experience software glitches or hardware failures.

-

A malfunctioning microcontroller can cause erratic behavior, such as random shutdowns or inconsistent cooling.

-

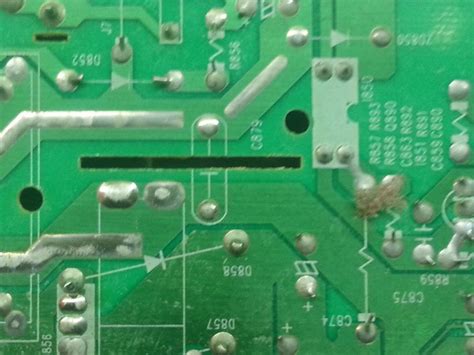

Corrosion and Dust Accumulation:

- Exposure to moisture and dust can cause corrosion on the PCB board and its components.

- Corrosion and dust accumulation can lead to electrical shorts, reduced performance, and eventual failure of the PCB board.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting can help extend the lifespan of the AC PCB board and ensure the efficient operation of the air conditioner. Here are some tips:

- Clean the PCB Board:

- Periodically clean the PCB board and its components using a soft brush or compressed air to remove dust and debris.

-

Ensure the air conditioner is unplugged and the PCB board is completely dry before reassembling.

-

Check for Visual Signs of Damage:

- Inspect the PCB board for any visible signs of damage, such as burnt components, cracked solder joints, or corrosion.

-

If any damage is found, consider replacing the affected components or the entire PCB board.

-

Test Capacitors:

- Use a multimeter to test the capacitance and resistance of the capacitors.

-

If the capacitance is significantly lower than the rated value or the resistance is high, replace the capacitor.

-

Monitor Voltage and Current:

- Use a multimeter to measure the voltage and current at various points on the PCB board.

-

Compare the readings with the manufacturer’s specifications to identify any abnormalities.

-

Update Firmware:

- If the air conditioner has a firmware update feature, ensure that the PCB board is running the latest version.

- Firmware updates can fix known bugs, improve performance, and add new features to the air conditioner.

Frequently Asked Questions (FAQ)

-

Q: Can I repair a damaged AC PCB board myself?

A: It is not recommended to repair a damaged PCB board yourself unless you have the necessary technical expertise and equipment. Improper handling can cause further damage or pose safety risks. It is best to seek the assistance of a professional AC technician. -

Q: How often should I clean the AC PCB board?

A: The frequency of cleaning depends on the operating environment and usage of the air conditioner. Generally, it is advisable to clean the PCB board at least once a year or whenever you notice excessive dust accumulation. -

Q: What are the signs that indicate a faulty AC PCB board?

A: Some common signs of a faulty PCB board include the air conditioner not turning on, inconsistent cooling, strange noises, error codes on the display, or the unit shutting down unexpectedly. -

Q: Can a faulty AC PCB board be replaced with a generic one?

A: It is not recommended to replace a faulty PCB board with a generic one. Each air conditioner model has a specific PCB board designed to work with its components and features. Using a generic board may lead to compatibility issues and suboptimal performance. -

Q: How long does an AC PCB board typically last?

A: The lifespan of an AC PCB board depends on various factors such as the quality of components, operating conditions, and maintenance. On average, a well-maintained PCB board can last between 5 to 10 years. However, some high-quality boards may last even longer with proper care.

Conclusion

The air conditioner PCB board is a vital component that ensures the efficient and reliable operation of the air conditioning system. Understanding its components, functions, and common problems can help you better maintain your air conditioner and troubleshoot issues when they arise.

Regular cleaning, inspection, and timely repairs by a qualified technician can significantly extend the lifespan of the PCB board and prevent costly breakdowns. By following the maintenance tips and being aware of the signs of a faulty board, you can ensure that your air conditioner remains in optimal condition, providing you with a comfortable and cool environment for years to come.

No responses yet