Introduction to Agile-PLM

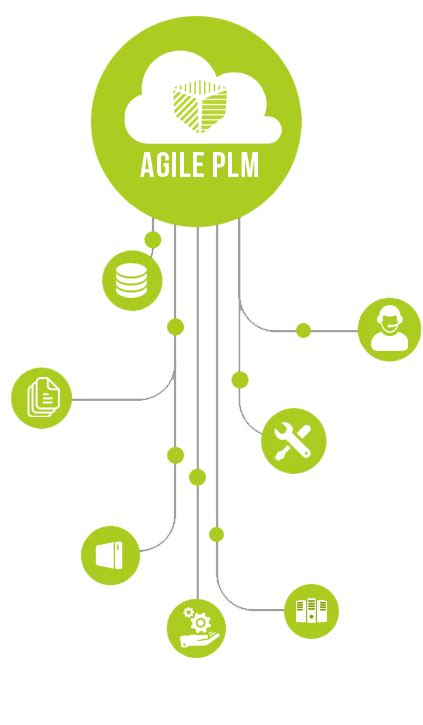

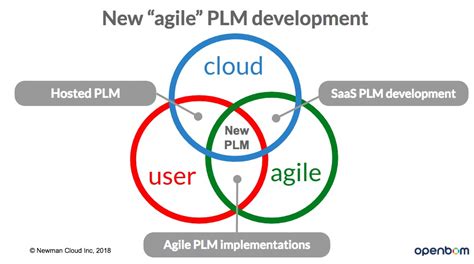

Agile Product Lifecycle Management (Agile-PLM) is a modern approach to managing the entire lifecycle of a product, from concept to retirement. It combines the principles of agile software development with traditional product lifecycle management (PLM) practices to create a more flexible, responsive, and efficient process for developing and managing products.

In the context of circuit board (CB) design, Agile-PLM can help teams streamline their design processes, improve collaboration, and ultimately deliver high-quality products faster. By adopting agile methodologies, CB design teams can better adapt to changing requirements, incorporate customer feedback, and continuously improve their designs.

Benefits of Agile-PLM in CB Design

- Faster time-to-market

- Improved collaboration and communication

- Increased flexibility and adaptability

- Enhanced product quality

- Better alignment with customer needs

Key Principles of Agile-PLM

1. Iterative and Incremental Development

One of the core principles of Agile-PLM is iterative and incremental development. Instead of trying to complete the entire product design in one go, the process is divided into smaller, manageable iterations. Each iteration focuses on delivering a working subset of the final product, allowing for early feedback and continuous improvement.

In CB design, this means breaking down the design process into smaller tasks, such as schematic design, layout, and verification. By completing these tasks in short iterations, teams can identify and address issues early on, reducing the risk of costly rework later in the development cycle.

2. Cross-Functional Teams

Agile-PLM emphasizes the importance of cross-functional teams, where members with different skills and expertise work together to deliver the product. This approach fosters collaboration, knowledge sharing, and a shared sense of ownership among team members.

In the context of CB design, a cross-functional team might include electrical engineers, PCB designers, mechanical engineers, and even manufacturing specialists. By working closely together, the team can ensure that the design meets all requirements, is manufacturable, and can be easily integrated into the final product.

3. Customer Collaboration

Another key principle of Agile-PLM is close collaboration with customers throughout the product development process. By involving customers early and often, teams can ensure that they are building the right product and incorporating feedback as they go.

For CB design teams, this means engaging with customers to understand their requirements, preferences, and constraints. Regular demos and reviews with customers can help validate design decisions and ensure that the final product meets their expectations.

4. Embracing Change

Agile-PLM recognizes that change is inevitable in product development and encourages teams to embrace it. By maintaining a flexible and adaptable approach, teams can respond to changing requirements, market conditions, or customer needs without derailing the entire project.

In CB design, this might involve using modular design techniques, parameterized components, or design reuse strategies to accommodate changes more easily. By anticipating and planning for change, teams can minimize its impact on the overall development timeline.

Implementing Agile-PLM in CB Design

1. Defining User Stories and Requirements

The first step in implementing Agile-PLM in CB design is to define user stories and requirements. User stories are short, simple descriptions of a feature or functionality from the perspective of the end-user. They help teams focus on delivering value to the customer and provide a basis for prioritizing work.

Example user story for a CB design project:

As a mobile phone user,

I want the device to have a long battery life,

so that I can use it for extended periods without recharging.

From this user story, the CB design team can derive specific requirements, such as:

– Low power consumption components

– Efficient power management circuitry

– Optimized board layout for minimal power loss

2. Planning and Prioritizing Work

Once user stories and requirements are defined, the next step is to plan and prioritize work. In Agile-PLM, this is typically done using a product backlog—a prioritized list of all the features, functionalities, and requirements for the product.

The product owner, who represents the customer’s interests, works with the team to prioritize items in the backlog based on their value, urgency, and dependencies. The team then selects items from the top of the backlog to work on in each iteration, or sprint.

For CB design projects, the backlog might include items such as:

1. Design power management circuitry

2. Select low-power components

3. Create schematic for main board

4. Layout main board

5. Verify main board design

6. Design and layout daughter boards

7. Integrate and test complete system

3. Conducting Sprints

Sprints are the heart of Agile-PLM. They are short, time-boxed iterations (usually 2-4 weeks) in which the team works to complete a set of backlog items. Each sprint follows a specific sequence of events:

- Sprint Planning: The team selects items from the backlog to work on during the sprint and defines the sprint goal.

- Daily Stand-ups: Brief daily meetings where team members share progress, plans, and any impediments.

- Sprint Review: A demo of the completed work to stakeholders and customers for feedback.

- Sprint Retrospective: A reflection on the sprint to identify improvements for the next iteration.

In CB design, a sprint might involve completing the schematic design and layout for a specific subsystem, such as the power management circuitry. The team would focus on this goal throughout the sprint, collaborating closely to ensure the design meets all requirements and is ready for review.

4. Continuous Integration and Testing

To ensure the quality and reliability of the CB design, Agile-PLM emphasizes continuous integration and testing. This means frequently merging work from different team members and running automated tests to catch any issues early.

For CB design projects, this might involve:

– Using version control systems to manage design files

– Automating design rule checks (DRC) and electrical rule checks (ERC)

– Running simulations to verify circuit behavior

– Conducting regular design reviews with the team and stakeholders

By integrating and testing the design continuously, teams can identify and resolve problems quickly, reducing the risk of costly delays or rework later in the development cycle.

Agile-PLM Tools and Techniques

To support the implementation of Agile-PLM in CB design, several tools and techniques can be used:

-

Kanban Boards: Visual tools for managing the flow of work, making it easy to see the status of each task and identify bottlenecks.

-

Burndown Charts: Graphs that show the amount of work remaining in a sprint, helping teams track progress and identify potential issues.

-

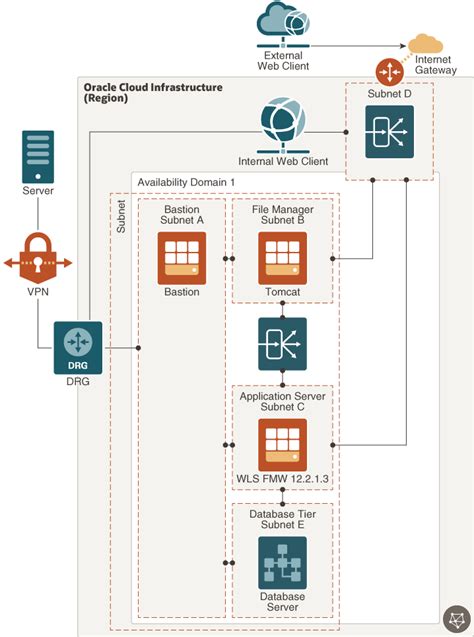

Design Collaboration Platforms: Cloud-based tools that enable real-time collaboration, version control, and design review, such as Altium 365 or Cadence OrCAD.

-

Automated Testing Tools: Software that automates design rule checks, electrical rule checks, and simulations, helping teams catch issues early and ensure design quality.

-

Continuous Integration Pipelines: Automated workflows that build, test, and deploy the CB design, ensuring that the latest version is always available for review and testing.

By leveraging these tools and techniques, CB design teams can streamline their processes, improve collaboration, and ultimately deliver better products faster.

Best Practices for Agile-PLM in CB Design

To ensure the success of Agile-PLM in CB design projects, consider the following best practices:

-

Foster a culture of collaboration and communication, encouraging team members to share ideas, concerns, and feedback openly.

-

Emphasize continuous learning and improvement, using sprint retrospectives to identify areas for growth and implement changes incrementally.

-

Maintain a clear and prioritized product backlog, ensuring that the team is always working on the most valuable and urgent items.

-

Use metrics and data to track progress, identify trends, and make informed decisions about the project.

-

Involve customers and stakeholders throughout the development process, seeking their feedback and input to ensure the design meets their needs.

By following these best practices, CB design teams can unlock the full potential of Agile-PLM, delivering high-quality products that meet customer needs and exceed expectations.

Challenges and Limitations of Agile-PLM

While Agile-PLM offers many benefits for CB design projects, it is not without its challenges and limitations:

-

Organizational Resistance: Implementing Agile-PLM often requires a significant shift in mindset and culture, which can be met with resistance from team members or managers who are accustomed to traditional, linear development processes.

-

Scalability: Agile-PLM works well for small to medium-sized projects, but scaling it to larger, more complex projects can be challenging, requiring careful coordination and management.

-

Regulatory Compliance: In industries with strict regulatory requirements, such as aerospace or medical devices, adopting Agile-PLM may be more difficult due to the need for extensive documentation and formal reviews.

-

Limited Upfront Planning: Agile-PLM emphasizes flexibility and adaptability, which can sometimes lead to insufficient upfront planning and architecture design, potentially impacting the overall system’s coherence and performance.

Despite these challenges, many organizations have successfully adopted Agile-PLM for CB design projects by tailoring the approach to their specific needs and constraints, and by providing adequate training and support to their teams.

The Future of Agile-PLM in CB Design

As the demand for faster, more innovative, and higher-quality products continues to grow, the adoption of Agile-PLM in CB design is likely to increase. Advances in technology, such as cloud computing, artificial intelligence, and the Internet of Things (IoT), will further enable and accelerate this trend.

Some potential future developments in Agile-PLM for CB design include:

-

Increased automation of design tasks, such as component selection, placement, and routing, using AI and machine learning algorithms.

-

Greater integration of PLM systems with other enterprise tools, such as ERP, MES, and CRM, enabling seamless data exchange and collaboration across the entire product lifecycle.

-

Enhanced Virtual Prototyping and simulation capabilities, allowing teams to test and validate designs in a fully digital environment before committing to physical prototypes.

-

Improved support for distributed and remote teams, with cloud-based collaboration platforms and virtual reality tools enabling real-time, immersive design reviews and workshops.

As these trends continue to evolve, CB design teams that embrace Agile-PLM will be well-positioned to deliver innovative, high-quality products that meet the ever-changing needs of their customers.

Frequently Asked Questions (FAQ)

-

What is Agile-PLM, and how does it differ from traditional PLM?

Agile-PLM is an approach that combines the principles of agile software development with traditional PLM practices. It emphasizes iterative development, cross-functional collaboration, customer involvement, and flexibility, while traditional PLM tends to be more linear, sequential, and document-driven. -

What are the benefits of using Agile-PLM in CB design projects?

Agile-PLM can help CB design teams deliver products faster, improve collaboration and communication, increase flexibility and adaptability, enhance product quality, and better align with customer needs. -

How do I get started with implementing Agile-PLM in my CB design team?

To get started with Agile-PLM, begin by defining user stories and requirements, planning and prioritizing work using a product backlog, and conducting short, focused sprints to deliver incremental value. Ensure that your team is trained in agile principles and practices, and foster a culture of collaboration and continuous improvement. -

What tools and techniques support Agile-PLM in CB design?

Several tools and techniques can support Agile-PLM in CB design, including Kanban boards, burndown charts, design collaboration platforms, automated testing tools, and continuous integration pipelines. These tools help teams visualize and manage their work, collaborate effectively, and ensure design quality. -

Can Agile-PLM be used for large, complex CB design projects?

Yes, Agile-PLM can be used for large and complex CB design projects, but it may require careful scaling and coordination. Strategies such as breaking down the project into smaller, manageable parts, using a hybrid agile-waterfall approach, or adopting agile frameworks like SAFe (Scaled Agile Framework) can help teams successfully apply Agile-PLM to larger projects.

Conclusion

Agile Product Lifecycle Management (Agile-PLM) is a powerful approach for managing CB design projects, offering numerous benefits such as faster time-to-market, improved collaboration, and enhanced product quality. By adopting agile principles and practices, CB design teams can better adapt to changing requirements, incorporate customer feedback, and continuously improve their designs.

To successfully implement Agile-PLM, teams should focus on defining user stories and requirements, planning and prioritizing work using a product backlog, conducting short, focused sprints, and leveraging tools and techniques that support collaboration, automation, and continuous integration.

While there are challenges and limitations to adopting Agile-PLM, such as organizational resistance and scalability concerns, many organizations have successfully overcome these obstacles by tailoring the approach to their specific needs and providing adequate training and support to their teams.

As technology continues to advance and the demand for faster, more innovative products grows, the future of Agile-PLM in CB design looks bright. By embracing this approach and staying at the forefront of industry trends, CB design teams can position themselves for success in delivering high-quality, customer-centric products that drive business value.

No responses yet