Introduction to PCB Materials

Printed Circuit Boards (PCBs) are the backbone of modern electronics, providing a reliable and efficient means of connecting electronic components. The choice of materials used in PCB fabrication plays a crucial role in determining the performance, durability, and cost of the final product. Two key materials used in PCB manufacturing are the core and prepreg. Understanding the differences between these materials is essential for designers to make informed decisions when creating PCBs.

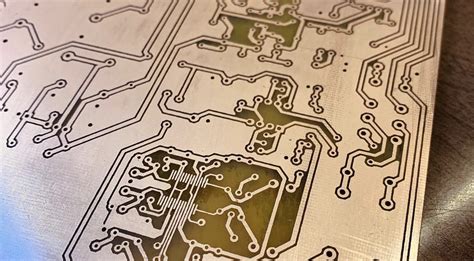

What is PCB Core Material?

PCB core material, also known as the substrate, is the foundation of a printed circuit board. It is a rigid, insulating material that provides mechanical support for the copper layers and components. The most common core materials used in PCB manufacturing are:

- FR-4 (Flame Retardant 4)

- CEM-1 (Composite Epoxy Material)

- CEM-3

- Polyimide

- PTFE (Polytetrafluoroethylene)

Each core material has its own unique properties, such as dielectric constant, thermal stability, and moisture resistance, which make them suitable for different applications.

FR-4 Core Material

FR-4 is the most widely used core material in PCB manufacturing. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. FR-4 offers a good balance of electrical, mechanical, and thermal properties, making it suitable for a wide range of applications. Some key characteristics of FR-4 include:

- Dielectric Constant (Dk): 4.3 – 4.6

- Dissipation Factor (Df): 0.02 – 0.03

- Thermal Decomposition Temperature (Td): 320°C – 340°C

- Moisture Absorption: 0.1% – 0.3%

CEM-1 and CEM-3 Core Materials

CEM-1 and CEM-3 are composite epoxy materials that offer a cost-effective alternative to FR-4. CEM-1 consists of a paper core with epoxy resin, while CEM-3 uses a non-woven fiberglass mat with epoxy resin. These materials are suitable for low-end applications with less demanding performance requirements.

Polyimide Core Material

Polyimide is a high-performance core material known for its excellent thermal stability and low dielectric constant. It is often used in high-temperature applications, such as aerospace and military electronics. Polyimide has a higher cost compared to FR-4 and CEM materials.

PTFE Core Material

PTFE, also known as Teflon, is a low-loss dielectric material with excellent high-frequency performance. It is often used in RF and microwave applications. PTFE has a low dielectric constant (2.1 – 2.3) and a very low dissipation factor (0.0002 – 0.0009), making it ideal for high-speed signal transmission.

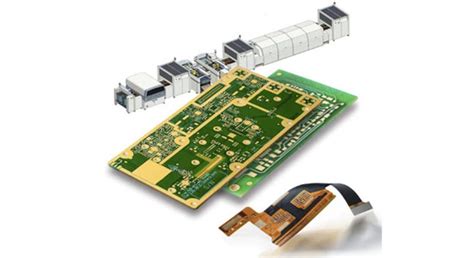

What is Prepreg Material?

Prepreg, short for pre-impregnated, is a reinforcing material used in multi-layer PCBs to bond the core layers together. It consists of a woven or non-woven fabric impregnated with a partially cured thermosetting resin, typically epoxy. During the lamination process, the prepreg melts and flows, bonding the core layers together and providing insulation between the copper layers.

Prepreg materials are classified based on their glass transition temperature (Tg), which determines the maximum operating temperature of the PCB. Common prepreg materials include:

- Standard FR-4 Prepreg (Tg: 130°C – 140°C)

- High Tg FR-4 Prepreg (Tg: 170°C – 180°C)

- Polyimide Prepreg (Tg: 250°C – 260°C)

The choice of prepreg material depends on the operating temperature, thermal stability, and performance requirements of the PCB.

Comparison of PCB Core and Prepreg Materials

| Property | PCB Core Material | Prepreg Material |

|---|---|---|

| Function | Provides mechanical support and insulation for copper layers | Bonds core layers together and provides insulation between copper layers |

| Composition | Rigid, insulating material (e.g., FR-4, CEM-1, Polyimide) | Woven or non-woven fabric impregnated with partially cured resin |

| Thickness | Typically 0.2mm – 3.2mm | Typically 0.05mm – 0.2mm |

| Glass Transition Temperature (Tg) | Depends on the specific material | Determines the maximum operating temperature of the PCB |

| Application | Single-layer and multi-layer PCBs | Multi-layer PCBs |

Factors to Consider When Selecting PCB Materials

When choosing PCB core and prepreg materials, designers must consider several factors to ensure optimal performance and reliability:

- Electrical Properties

- Dielectric Constant (Dk)

- Dissipation Factor (Df)

-

Insulation Resistance

-

Thermal Properties

- Glass Transition Temperature (Tg)

- Thermal Decomposition Temperature (Td)

-

Coefficient of Thermal Expansion (CTE)

-

Mechanical Properties

- Flexural Strength

- Tensile Strength

-

Elongation

-

Environmental Factors

- Operating Temperature Range

- Humidity Resistance

-

Flammability Rating

-

Manufacturing Considerations

- Dimensional Stability

- Drilling and Machining Properties

-

Lamination Compatibility

-

Cost and Availability

- Material Cost

- Lead Time

- Minimum Order Quantity

Best Practices for Selecting PCB Materials

- Understand the application requirements, including electrical, thermal, and mechanical constraints.

- Choose materials that meet the performance specifications while considering cost and availability.

- Consult with PCB manufacturers and material suppliers to ensure compatibility and manufacturability.

- Consider using high-performance materials, such as high Tg FR-4 or polyimide, for demanding applications.

- Use standard materials, like FR-4, whenever possible to reduce cost and lead time.

- Perform material characterization and testing to validate the selected materials’ performance.

Conclusion

Selecting the right PCB core and prepreg materials is crucial for designing reliable and high-performance printed circuit boards. By understanding the properties and differences between these materials, designers can make informed decisions that balance performance, cost, and manufacturability. Careful consideration of application requirements, material properties, and manufacturing constraints will help ensure the success of PCB designs.

Frequently Asked Questions (FAQ)

- What is the difference between PCB core and prepreg materials?

-

PCB core material is the rigid, insulating substrate that provides mechanical support for the copper layers and components. Prepreg material is a reinforcing material used to bond the core layers together and provide insulation between copper layers in multi-layer PCBs.

-

Which is the most commonly used PCB core material?

-

FR-4 is the most widely used PCB core material. It offers a good balance of electrical, mechanical, and thermal properties, making it suitable for a wide range of applications.

-

What factors should be considered when selecting PCB materials?

-

When choosing PCB materials, designers should consider electrical properties, thermal properties, mechanical properties, environmental factors, manufacturing considerations, cost, and availability.

-

What is the difference between standard FR-4 and high Tg FR-4 prepreg materials?

-

Standard FR-4 prepreg has a glass transition temperature (Tg) of 130°C – 140°C, while high Tg FR-4 prepreg has a Tg of 170°C – 180°C. High Tg FR-4 is suitable for applications that require higher thermal stability and performance.

-

Can different PCB core and prepreg materials be mixed in a single PCB design?

- Yes, different PCB core and prepreg materials can be used in a single PCB design to optimize performance and cost. However, designers must ensure compatibility between the materials and consider the manufacturing constraints when mixing materials.

No responses yet