What is PCB Copper Thickness?

PCB copper thickness refers to the thickness of the copper layer on a printed circuit board (PCB). The copper layer is responsible for conducting electrical signals between components on the board. The thickness of this layer is typically measured in ounces per square foot (oz/ft²) or microns (µm).

Common PCB Copper Thicknesses

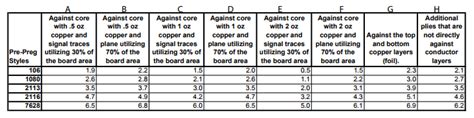

| Copper Weight (oz/ft²) | Thickness (µm) |

|---|---|

| 0.5 oz | 17.5 µm |

| 1 oz | 35 µm |

| 2 oz | 70 µm |

| 3 oz | 105 µm |

| 4 oz | 140 µm |

The most commonly used copper thickness in PCBs is 1 oz/ft², which equates to a thickness of approximately 35 microns. However, depending on the specific requirements of the PCB, other thicknesses may be used.

Factors Affecting the Choice of PCB Copper Thickness

Several factors influence the choice of copper thickness for a PCB, including:

Current Carrying Capacity

The current carrying capacity of a PCB is directly related to the thickness of the copper layer. Thicker copper layers can carry more current without overheating or experiencing voltage drops. The table below shows the relationship between copper thickness and current carrying capacity:

| Copper Thickness (oz/ft²) | Current Carrying Capacity (A/mm) |

|---|---|

| 0.5 oz | 0.2 |

| 1 oz | 0.4 |

| 2 oz | 0.8 |

| 3 oz | 1.2 |

| 4 oz | 1.6 |

Signal Integrity

The thickness of the copper layer can also affect signal integrity. Thinner copper layers are more prone to signal loss and distortion, especially at high frequencies. Thicker copper layers provide better signal integrity and reduce the risk of signal degradation.

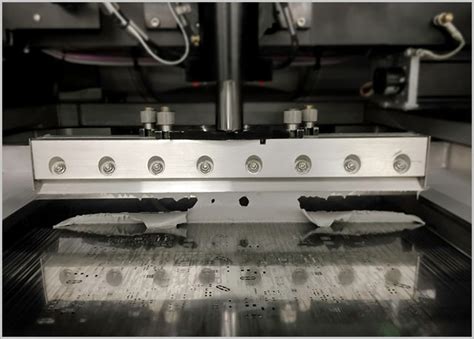

Manufacturing Considerations

The choice of copper thickness also depends on manufacturing considerations. Thinner copper layers are easier to etch and can result in finer trace widths and spacing. However, thinner layers are also more prone to manufacturing defects and may require more careful handling during the PCB fabrication process.

Cost

Thicker copper layers require more material and can increase the overall cost of the PCB. Therefore, the choice of copper thickness must balance performance requirements with cost constraints.

PCB Copper Thickness and High-Current Applications

In high-current applications, such as power electronics or automotive systems, thicker copper layers are often necessary to ensure adequate current carrying capacity and to minimize voltage drops. In these cases, copper thicknesses of 2 oz/ft² or greater may be used.

Calculating the Required Copper Thickness for High-Current Applications

To determine the required copper thickness for a high-current application, designers must consider the maximum current the PCB needs to carry and the allowable voltage drop across the copper traces. The following equation can be used to calculate the minimum required copper thickness:

T = (I * L) / (K * ΔV * W)

Where:

– T = Copper thickness (oz/ft²)

– I = Maximum current (A)

– L = Trace length (ft)

– K = Resistivity constant (0.67 for copper)

– ΔV = Allowable voltage drop (V)

– W = Trace width (in)

For example, if a PCB needs to carry a maximum current of 10A over a trace length of 6 inches, with an allowable voltage drop of 0.1V and a trace width of 0.1 inches, the minimum required copper thickness would be:

T = (10A * 0.5ft) / (0.67 * 0.1V * 0.1in)

T = 7.46 oz/ft²

In this case, a copper thickness of 8 oz/ft² or greater would be recommended to ensure adequate current carrying capacity and minimize voltage drop.

PCB Copper Thickness and High-Frequency Applications

In high-frequency applications, such as RF and microwave circuits, the choice of copper thickness can have a significant impact on signal integrity and performance. Thinner copper layers are often preferred in these applications to minimize skin effect and reduce signal loss.

Skin Effect and PCB Copper Thickness

Skin effect is a phenomenon where high-frequency currents tend to flow along the surface of a conductor rather than uniformly through its cross-section. The depth at which the current density falls to 1/e (approximately 37%) of its value at the surface is called the skin depth. The skin depth is frequency-dependent and can be calculated using the following equation:

δ = sqrt(ρ / (π * f * μ))

Where:

– δ = Skin depth (m)

– ρ = Resistivity of the conductor (Ω·m)

– f = Frequency (Hz)

– μ = Magnetic permeability of the conductor (H/m)

As the frequency increases, the skin depth decreases, meaning that the current flows in a thinner layer near the surface of the conductor. To minimize the impact of skin effect and reduce signal loss, thinner copper layers are often used in high-frequency PCBs.

Microstrip and Stripline Transmission Lines

In high-frequency PCBs, microstrip and stripline transmission lines are commonly used to route signals. The characteristic impedance of these transmission lines depends on the copper thickness, dielectric constant of the substrate, and the width of the trace. The following equations can be used to calculate the characteristic impedance of microstrip and stripline transmission lines:

Microstrip:

Z0 = (87 / sqrt(εr + 1.41)) * ln(5.98 * h / (0.8 * w + t))

Stripline:

Z0 = (60 / sqrt(εr)) * ln(4 * h / (0.67 * (0.8 * w + t)))

Where:

– Z0 = Characteristic impedance (Ω)

– εr = Dielectric constant of the substrate

– h = Dielectric thickness (mm)

– w = Trace width (mm)

– t = Copper thickness (mm)

By carefully selecting the copper thickness and trace width, designers can achieve the desired characteristic impedance and minimize signal reflections and distortions in high-frequency PCBs.

FAQ

1. What is the most common PCB copper thickness?

The most common PCB copper thickness is 1 oz/ft², which corresponds to a thickness of approximately 35 microns.

2. How does copper thickness affect current carrying capacity?

Thicker copper layers can carry more current without overheating or experiencing voltage drops. The current carrying capacity is directly proportional to the copper thickness.

3. Why are thinner copper layers preferred in high-frequency PCBs?

Thinner copper layers are preferred in high-frequency PCBs to minimize the impact of skin effect and reduce signal loss. As the frequency increases, the current tends to flow in a thinner layer near the surface of the conductor.

4. What factors influence the choice of PCB copper thickness?

Several factors influence the choice of PCB copper thickness, including current carrying capacity, signal integrity, manufacturing considerations, and cost.

5. How can I calculate the required copper thickness for a high-current application?

To calculate the required copper thickness for a high-current application, you need to consider the maximum current the PCB needs to carry, the allowable voltage drop across the copper traces, the trace length, and the trace width. You can use the equation: T = (I * L) / (K * ΔV * W), where T is the copper thickness (oz/ft²), I is the maximum current (A), L is the trace length (ft), K is the resistivity constant (0.67 for copper), ΔV is the allowable voltage drop (V), and W is the trace width (in).

No responses yet