Introduction to PCB Prototyping

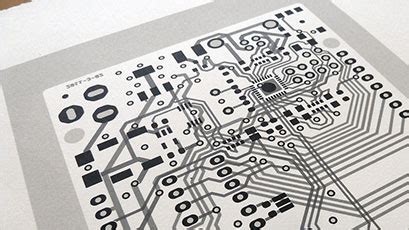

PCB (Printed Circuit Board) prototyping is a crucial step in the development of electronic devices. It allows designers and engineers to test and validate their designs before moving into mass production. Traditional PCB prototyping methods, such as etching and milling, have been used for decades. However, with the advent of 3D printing technology, PCB prototyping has undergone a significant transformation.

The Rise of 3D Printing in PCB Prototyping

3D printing, also known as additive manufacturing, has been around since the 1980s. However, it was not until recently that this technology started to be used for PCB prototyping. The ability to print complex geometries and the availability of conductive materials have made 3D printing a viable option for creating PCB prototypes.

Advantages of 3D Printing in PCB Prototyping

- Rapid prototyping: 3D printing allows for quick and easy creation of PCB prototypes, reducing the time and cost associated with traditional methods.

- Design freedom: 3D printing enables designers to create complex geometries and shapes that are not possible with traditional PCB manufacturing methods.

- Customization: 3D printing allows for easy customization of PCB designs, enabling designers to make changes on the fly without incurring significant costs.

- Cost-effective: 3D printing is a cost-effective solution for low-volume production runs, making it ideal for prototyping and small batch manufacturing.

3D Printing Technologies Used in PCB Prototyping

There are several 3D printing technologies that are used in PCB prototyping. Each technology has its own advantages and limitations.

Fused Deposition Modeling (FDM)

FDM is the most common 3D printing technology used in PCB prototyping. It works by extruding a thermoplastic material, such as ABS or PLA, through a heated nozzle to create the desired shape. FDM is relatively inexpensive and easy to use, making it a popular choice for hobbyists and small businesses.

Stereolithography (SLA)

SLA is a 3D printing technology that uses a laser to cure and harden a photopolymer resin. SLA produces high-quality, smooth surfaces and is often used for creating detailed prototypes. However, it is more expensive than FDM and requires post-processing to remove the support structures.

Selective Laser Sintering (SLS)

SLS is a 3D printing technology that uses a laser to sinter powdered materials, such as nylon or metal, into a solid object. SLS is often used for creating functional prototypes and end-use parts. However, it is more expensive than FDM and SLA and requires specialized equipment.

Materials Used in 3D Printed PCB Prototypes

The materials used in 3D printed PCB prototypes vary depending on the 3D printing technology used. However, there are some common materials that are used across different technologies.

Conductive Materials

Conductive materials are essential for creating functional PCB prototypes. These materials are used to create the conductive traces and pads on the PCB. Some common conductive materials used in 3D printed PCB prototypes include:

- Conductive filaments (for FDM)

- Conductive resins (for SLA)

- Conductive inks (for inkjet printing)

Insulating Materials

Insulating materials are used to create the substrate of the PCB and to insulate the conductive traces. Some common insulating materials used in 3D printed PCB prototypes include:

- PLA (for FDM)

- ABS (for FDM)

- Photopolymer resins (for SLA)

- Nylon (for SLS)

Applications of 3D Printed PCB Prototypes

3D printed PCB prototypes have a wide range of applications across different industries. Some of the most common applications include:

Consumer Electronics

3D printed PCB prototypes are often used in the development of consumer electronics, such as smartphones, tablets, and wearables. These prototypes allow designers to test and validate their designs before moving into mass production.

Medical Devices

3D printed PCB prototypes are also used in the development of medical devices, such as implantable sensors and wearable health monitors. These prototypes allow for rapid iteration and testing of designs, ensuring that the final product meets the necessary safety and performance requirements.

Aerospace and Defense

3D printed PCB prototypes are used in the aerospace and defense industries for creating custom electronic components and systems. These prototypes allow for quick and easy testing of designs in harsh environments and under extreme conditions.

Challenges and Limitations of 3D Printed PCB Prototypes

While 3D printed PCB prototypes offer many advantages over traditional prototyping methods, there are also some challenges and limitations to consider.

Material Properties

The material properties of 3D printed PCB prototypes may not be as robust as those of traditionally manufactured PCBs. This can impact the performance and reliability of the final product.

Resolution and Accuracy

The resolution and accuracy of 3D printed PCB prototypes may not be as high as those of traditionally manufactured PCBs. This can impact the functionality and reliability of the final product.

Post-Processing

3D printed PCB prototypes often require post-processing, such as cleaning and curing, to achieve the desired properties and performance. This can add time and cost to the prototyping process.

Future of 3D Printed PCB Prototypes

Despite the challenges and limitations, the future of 3D printed PCB prototypes looks bright. As 3D printing technology continues to evolve and improve, we can expect to see even more advanced and sophisticated PCB prototypes being created.

Multi-Material 3D Printing

One of the most promising developments in 3D printed PCB prototyping is multi-material 3D printing. This technology allows for the creation of PCBs with multiple materials, such as conductive and insulating materials, in a single print. This can simplify the prototyping process and reduce the need for post-processing.

Embedded Electronics

Another exciting development in 3D printed PCB prototyping is the ability to embed electronic components directly into the PCB. This can reduce the size and complexity of the final product and improve its performance and reliability.

Increased Adoption

As the benefits of 3D printed PCB prototyping become more widely recognized, we can expect to see increased adoption of this technology across different industries. This will drive further innovation and development in the field, leading to even more advanced and sophisticated PCB prototypes.

FAQs

What is PCB prototyping?

PCB prototyping is the process of creating a functional prototype of a printed circuit board (PCB) before moving into mass production. This allows designers and engineers to test and validate their designs and make any necessary changes before committing to a full production run.

What are the advantages of 3D printing in PCB prototyping?

The advantages of 3D printing in PCB prototyping include rapid prototyping, design freedom, customization, and cost-effectiveness. 3D printing allows for quick and easy creation of complex geometries and shapes, and enables designers to make changes on the fly without incurring significant costs.

What materials are used in 3D printed PCB prototypes?

The materials used in 3D printed PCB prototypes vary depending on the 3D printing technology used. Common materials include conductive filaments, resins, and inks for creating the conductive traces and pads, and insulating materials such as PLA, ABS, photopolymer resins, and nylon for creating the substrate and insulating the conductive traces.

What are the limitations of 3D printed PCB prototypes?

Some limitations of 3D printed PCB prototypes include material properties that may not be as robust as traditionally manufactured PCBs, lower resolution and accuracy compared to traditional methods, and the need for post-processing to achieve the desired properties and performance.

What is the future of 3D printed PCB prototypes?

The future of 3D printed PCB prototypes looks bright, with developments such as multi-material 3D printing, embedded electronics, and increased adoption across different industries driving further innovation and development in the field. As the technology continues to evolve and improve, we can expect to see even more advanced and sophisticated PCB prototypes being created.

| Advantages of 3D Printing in PCB Prototyping | Traditional PCB Prototyping Methods |

|---|---|

| Rapid prototyping | Slower and more time-consuming |

| Design freedom | Limited design options |

| Customization | Limited customization options |

| Cost-effective for low-volume production | High costs for low-volume production |

Conclusion

3D printed PCB prototypes are revolutionizing the way we design and develop electronic devices. With the ability to create complex geometries, customize designs on the fly, and produce prototypes quickly and cost-effectively, 3D printing is changing the landscape of PCB design.

While there are still challenges and limitations to overcome, the future of 3D printed PCB prototyping looks bright. As the technology continues to evolve and improve, we can expect to see even more advanced and sophisticated PCB prototypes being created, driving innovation and development across different industries.

No responses yet