What is a BOM?

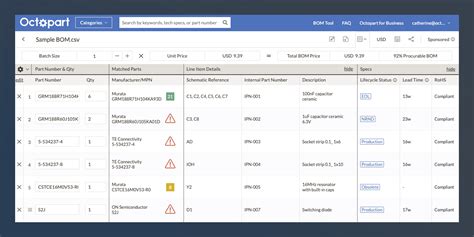

A Bill of Materials (BOM) is a detailed list of all the components, materials, and quantities required to manufacture a product. In the context of PCB manufacturing, a BOM typically includes the following information:

- Part numbers

- Descriptions

- Quantities

- Manufacturers

- Suppliers

- Costs

A BOM serves as a blueprint for the PCB manufacturing process, ensuring that all the necessary components are available and that the manufacturing process runs smoothly.

Why is BOM Management Important?

Effective BOM management is crucial for several reasons:

-

Ensures Accuracy: A well-managed BOM ensures that all the necessary components are included in the manufacturing process, reducing the risk of errors and delays.

-

Reduces Costs: By accurately tracking the quantities and costs of components, BOM management helps to minimize waste and reduce overall manufacturing costs.

-

Improves Efficiency: A centralized BOM management system allows teams to access up-to-date information, streamlining communication and collaboration.

-

Facilitates Revision Control: BOM management tools enable teams to track changes and revisions to the BOM, ensuring that the most current version is always used.

-

Enhances Quality Control: By providing a clear and accurate list of components, BOM management helps to maintain the quality and reliability of the final product.

Types of BOM Management Tools

There are several types of BOM management tools available, each with its own strengths and features. Some of the most common types include:

-

Spreadsheet-based Tools: Simple spreadsheet applications, such as Microsoft Excel or Google Sheets, can be used to create and manage BOMs. While these tools are readily available and easy to use, they lack advanced features and can become cumbersome for complex projects.

-

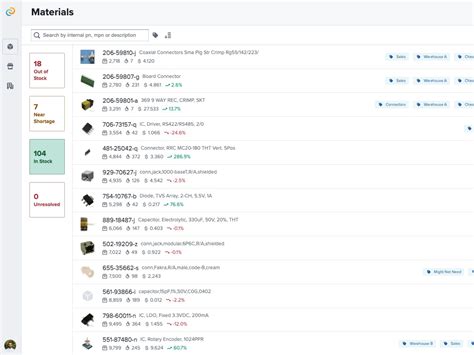

Dedicated BOM Management Software: Specialized BOM management software, such as OpenBOM or Arena BOM, offer a range of features specifically designed for managing BOMs. These tools often include revision control, multi-user collaboration, and integration with other systems, such as ERP or PLM.

-

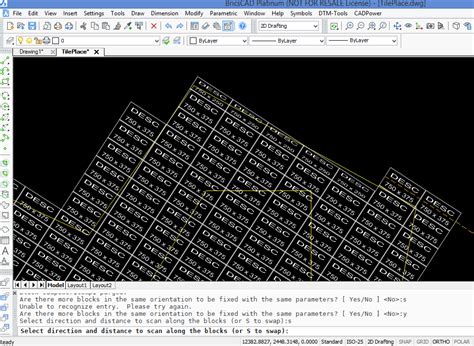

PLM (Product Lifecycle Management) Systems: PLM systems, such as Siemens Teamcenter or PTC Windchill, provide a comprehensive platform for managing product data throughout the entire lifecycle. These systems often include BOM management as a core feature, along with other capabilities such as CAD integration and change management.

-

ERP (Enterprise Resource Planning) Systems: ERP systems, such as SAP or Oracle, are designed to manage various business processes, including manufacturing and supply chain management. Many ERP systems include BOM management functionality, allowing for seamless integration with other business processes.

Key Features of BOM Management Tools

When selecting a BOM management tool, it is important to consider the specific needs of your organization and the complexity of your PCB manufacturing process. Some of the key features to look for in a BOM management tool include:

-

Centralized Database: A centralized database ensures that all team members have access to the most up-to-date BOM information, reducing the risk of errors and inconsistencies.

-

Revision Control: Revision control features allow teams to track changes to the BOM over time, ensuring that the most current version is always used.

-

Multi-User Collaboration: Collaboration features enable multiple team members to work on the BOM simultaneously, streamlining communication and reducing the risk of errors.

-

Integration with Other Systems: Integration with other systems, such as ERP, PLM, or CAD, allows for seamless data exchange and reduces the need for manual data entry.

-

Automated Part Sourcing: Some BOM management tools include automated part sourcing capabilities, which can help to identify the best suppliers and pricing for each component.

-

Reporting and Analytics: Reporting and analytics features provide valuable insights into BOM costs, component usage, and supplier performance.

Implementing a BOM Management Tool

Implementing a BOM management tool requires careful planning and execution. Here are some best practices to follow:

-

Define Your Requirements: Clearly define your organization’s specific needs and requirements for BOM management, including the size and complexity of your BOMs, the number of users, and the required integrations.

-

Evaluate Available Options: Research and evaluate the various BOM management tools available, considering factors such as cost, features, ease of use, and scalability.

-

Involve Key Stakeholders: Involve key stakeholders, such as engineering, manufacturing, and procurement teams, in the selection and implementation process to ensure buy-in and alignment.

-

Provide Training and Support: Provide comprehensive training and support to ensure that all team members are comfortable using the new BOM management tool.

-

Establish Standard Processes: Establish standard processes and guidelines for creating, updating, and maintaining BOMs to ensure consistency and accuracy.

-

Continuously Improve: Continuously monitor and improve your BOM management processes, incorporating feedback from team members and adapting to changing needs and requirements.

Benefits of Effective BOM Management

Effective BOM management offers several benefits for PCB manufacturing:

-

Reduced Costs: By minimizing waste, reducing errors, and optimizing component sourcing, effective BOM management can significantly reduce manufacturing costs.

-

Improved Quality: Accurate and up-to-date BOMs ensure that the right components are used in the manufacturing process, resulting in higher-quality PCBs.

-

Faster Time-to-Market: Streamlined BOM management processes enable faster design iterations and reduce the time required to bring new products to market.

-

Enhanced Collaboration: Centralized BOM management tools foster collaboration and communication among team members, reducing the risk of errors and delays.

-

Better Decision-Making: Comprehensive BOM data and analytics provide valuable insights into component usage, costs, and supplier performance, enabling better decision-making.

BOM Management Best Practices

To ensure the success of your BOM management process, consider the following best practices:

-

Standardize BOM Formats: Establish a standardized format for your BOMs, including consistent naming conventions, units of measure, and data fields.

-

Maintain Accurate Data: Regularly review and update your BOM data to ensure accuracy and currency.

-

Use Automated Tools: Leverage Automated BOM management tools to streamline processes and reduce the risk of errors.

-

Collaborate with Suppliers: Work closely with your suppliers to ensure that they have accurate and up-to-date BOM information.

-

Conduct Regular Audits: Conduct regular audits of your BOM management processes to identify areas for improvement and ensure compliance with standards and regulations.

FAQ

-

What is the difference between a BOM and a parts list?

A BOM is a comprehensive list of all the components, materials, and quantities required to manufacture a product, while a parts list is a simplified version of a BOM that typically only includes part numbers and quantities. -

Can I use a spreadsheet to manage my BOMs?

Yes, spreadsheets can be used to manage simple BOMs. However, for complex projects with multiple revisions and users, dedicated BOM management tools are recommended. -

How often should I update my BOMs?

BOMs should be updated whenever there are changes to the product design, components, or suppliers. It is important to establish a regular review and update process to ensure that BOMs remain accurate and current. -

What should I consider when selecting a BOM management tool?

When selecting a BOM management tool, consider factors such as your organization’s specific needs, the size and complexity of your BOMs, the number of users, required integrations, and budget. -

How can I ensure the accuracy of my BOM data?

To ensure the accuracy of your BOM data, establish standard processes for creating and maintaining BOMs, regularly review and update BOM information, and conduct periodic audits to identify and correct any discrepancies.

Conclusion

Effective BOM management is essential for streamlining the PCB manufacturing process, reducing costs, improving quality, and accelerating time-to-market. By selecting the right BOM management tools and following best practices, organizations can optimize their BOM management processes and ensure the success of their PCB manufacturing projects.

| BOM Management Tool | Key Features | Best Suited For |

|---|---|---|

| Spreadsheets | – Simple and readily available – Easy to use – Low cost |

– Small, simple projects – Limited users and revisions |

| Dedicated BOM Software | – Revision control – Multi-user collaboration – Integration with other systems |

– Medium to large projects – Multiple users and revisions – Integration with ERP or PLM |

| PLM Systems | – Comprehensive product lifecycle management – CAD integration – Change management |

– Large, complex projects – Full product lifecycle management – Integration with multiple systems |

| ERP Systems | – Integration with business processes – Manufacturing and supply chain management – Financial management |

– Organizations with existing ERP systems – Projects requiring integration with business processes |

By understanding the importance of BOM management, selecting the right tools, and implementing best practices, organizations can optimize their PCB manufacturing processes and deliver high-quality products to their customers.

No responses yet