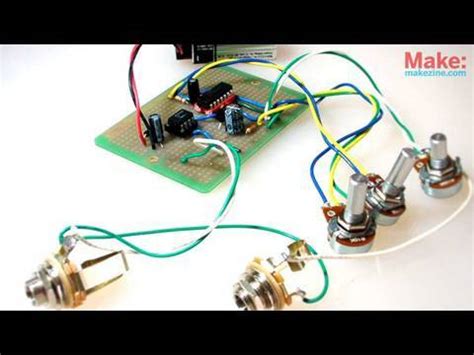

What is Circuit Prototyping?

Circuit prototyping is the process of creating a preliminary version of an electronic circuit to test its functionality, performance, and design. This process is essential for identifying and fixing any issues before the final product is manufactured. Traditionally, circuit prototyping has been a time-consuming and expensive process, requiring specialized equipment and expertise.

The Benefits of 3D Printing for Circuit Prototyping

3D printing has emerged as a game-changing technology for circuit prototyping, offering several key benefits over traditional methods:

-

Speed: 3D printing allows for rapid prototyping of circuit boards, reducing the time it takes to go from concept to physical prototype.

-

Cost-effectiveness: 3D printing is often more cost-effective than traditional prototyping methods, especially for small-scale production runs.

-

Flexibility: 3D printing allows for greater design flexibility, enabling designers to create complex geometries and structures that would be difficult or impossible to achieve with traditional manufacturing methods.

-

Accessibility: 3D printers are becoming increasingly affordable and user-friendly, making them accessible to a wider range of businesses and individuals.

The 3D Printing Process for Circuit Boards

The process of 3D printing circuit boards involves several key steps:

-

Design: The first step is to create a digital 3D model of the circuit board using computer-aided design (CAD) software.

-

Slicing: The 3D model is then “sliced” into thin layers using specialized software, which generates instructions for the 3D printer to follow.

-

Printing: The 3D printer then builds the circuit board layer by layer, using a variety of materials such as conductive filaments, resins, or inks.

-

Post-processing: After printing, the circuit board may require additional post-processing steps such as curing, cleaning, or assembly.

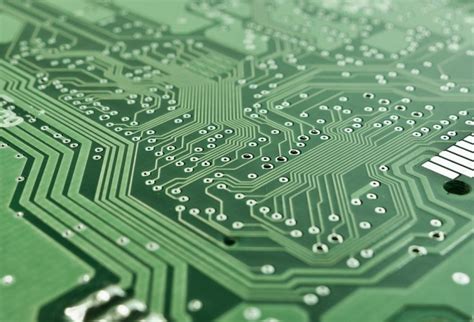

Materials for 3D Printing Circuit Boards

There are several materials available for 3D printing circuit boards, each with its own unique properties and advantages:

| Material | Description | Advantages |

|---|---|---|

| Conductive Filament | A thermoplastic filament infused with conductive particles, such as carbon or metal. | Inexpensive, easy to use, and compatible with most FDM 3D printers. |

| Conductive Resin | A photopolymer resin infused with conductive particles, such as silver or copper. | High resolution, smooth surface finish, and excellent electrical conductivity. |

| Conductive Ink | A liquid ink infused with conductive particles, such as silver or graphene. | Can be printed on a variety of substrates, including flexible materials. |

Applications of 3D Printed Circuit Boards

3D printed circuit boards have a wide range of applications across various industries, including:

-

Consumer Electronics: 3D printing is being used to create prototypes of consumer electronics products, such as smartphones, wearables, and IoT devices.

-

Aerospace and Defense: 3D printed circuit boards are being used in the aerospace and defense industries for applications such as satellite components, UAVs, and military equipment.

-

Medical Devices: 3D printing is being used to create custom medical devices, such as prosthetics, implants, and diagnostic tools.

-

Automotive: 3D printed circuit boards are being used in the automotive industry for applications such as sensors, control modules, and infotainment systems.

Challenges and Limitations of 3D Printing Circuit Boards

While 3D printing offers many benefits for circuit prototyping, there are also some challenges and limitations to consider:

-

Resolution: The resolution of 3D printed circuit boards is often lower than that of traditionally manufactured boards, which can impact performance and reliability.

-

Materials: The range of materials available for 3D printing circuit boards is still relatively limited compared to traditional manufacturing methods.

-

Scalability: 3D printing is often not suitable for large-scale production runs, as it can be slower and more expensive than traditional manufacturing methods.

-

Post-processing: 3D printed circuit boards often require additional post-processing steps, which can add time and complexity to the prototyping process.

Future Developments in 3D Printing for Circuit Prototyping

As 3D printing technology continues to advance, we can expect to see several key developments in the field of circuit prototyping:

-

Multi-material printing: The ability to print with multiple materials in a single print job could enable the creation of more complex and functional circuit boards.

-

Embedded components: The integration of electronic components directly into the 3D printed structure could streamline the assembly process and enable new design possibilities.

-

Improved resolution: Advancements in 3D printing technology are likely to improve the resolution and accuracy of printed circuit boards, enabling higher performance and reliability.

-

Faster printing speeds: As 3D printers become faster and more efficient, the time required to create a prototype circuit board will continue to decrease.

Frequently Asked Questions (FAQ)

-

Q: What is the cost of 3D printing a circuit board compared to traditional manufacturing methods?

A: The cost of 3D printing a circuit board can vary depending on the size, complexity, and materials used. In general, 3D printing is more cost-effective for small-scale production runs and prototypes, while traditional manufacturing methods are more economical for larger production volumes. -

Q: What software is used to design 3D printed circuit boards?

A: There are several software options available for designing 3D printed circuit boards, including Autodesk Fusion 360, Altium Designer, and KiCad. These software packages allow designers to create 3D models of circuit boards and generate the necessary files for 3D printing. -

Q: Can 3D printed circuit boards be used for high-frequency applications?

A: 3D printed circuit boards can be used for high-frequency applications, but the performance may be limited by the resolution and materials used. Conductive resins and inks are often better suited for high-frequency applications than conductive filaments. -

Q: How durable are 3D printed circuit boards compared to traditionally manufactured boards?

A: The durability of 3D printed circuit boards can vary depending on the materials used and the post-processing steps applied. In general, 3D printed circuit boards may be less durable than traditionally manufactured boards, but this can be mitigated through careful design and material selection. -

Q: Can 3D printed circuit boards be used for production-grade products?

A: While 3D printed circuit boards are often used for prototyping and small-scale production runs, they can also be used for production-grade products in some cases. However, this depends on the specific application, performance requirements, and production volume.

Conclusion

3D printing is revolutionizing the way we create circuit boards for fast prototyping, offering several key benefits over traditional manufacturing methods. From speed and cost-effectiveness to flexibility and accessibility, 3D printing is enabling designers and engineers to bring their ideas to life faster and more efficiently than ever before.

As the technology continues to evolve, we can expect to see even more exciting developments in the field of 3D printed circuit boards, from multi-material printing and embedded components to improved resolution and faster printing speeds.

Whether you’re a seasoned electronics engineer or a hobbyist just getting started, 3D printing offers a powerful tool for circuit prototyping that can help you turn your ideas into reality faster and more cost-effectively than ever before. So why not give it a try and see what you can create?

No responses yet