Introduction to Li-Po Battery chargers

Lithium-Polymer (Li-Po) batteries have become increasingly popular in recent years due to their high energy density, lightweight, and compact size. These batteries are commonly used in various electronic devices, such as smartphones, laptops, drones, and RC vehicles. To ensure the longevity and safe operation of Li-Po batteries, it is essential to use a dedicated charger designed specifically for this battery type. In this comprehensive article, we will dive into the world of Li-Po battery charger circuits, covering everything you need to know to design and understand these vital components.

Understanding Li-Po Battery Characteristics

Before delving into the details of Li-Po charger circuits, it is crucial to understand the characteristics of Li-Po batteries. Li-Po batteries are composed of multiple cells connected in series or parallel to achieve the desired voltage and capacity. Each Li-Po cell has a nominal voltage of 3.7V and can be charged up to 4.2V. Overcharging or discharging a Li-Po battery beyond its safe limits can lead to reduced battery life, performance degradation, and even potential fire hazards.

| Parameter | Value |

|---|---|

| Nominal Voltage | 3.7V |

| Charging Voltage | 4.2V |

| Discharging Cut-off Voltage | 3.0V |

| Maximum Charging Current | 1C |

| Maximum Discharging Current | Varies (depending on battery specs) |

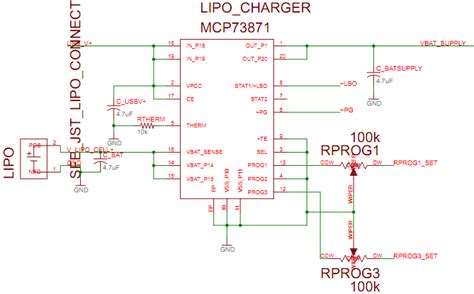

Key Components of a Li-Po Charger Circuit

A Li-Po charger circuit consists of several essential components that work together to ensure safe and efficient charging of the battery. Let’s take a closer look at each component:

Microcontroller

The heart of a Li-Po charger circuit is a microcontroller, which manages the charging process and monitors various parameters. Popular microcontrollers used in Li-Po charger circuits include:

- Arduino (AVR-based)

- PIC microcontrollers

- STM32 microcontrollers

The microcontroller runs the charging algorithm, controls the charging current and voltage, and communicates with other components in the circuit.

Voltage Regulator

A voltage regulator is used to step down the input voltage to the required charging voltage for the Li-Po battery. The most common type of voltage regulator used in Li-Po charger circuits is a switch-mode power supply (SMPS), such as a buck converter. The voltage regulator ensures a stable and accurate charging voltage, typically 4.2V for Li-Po batteries.

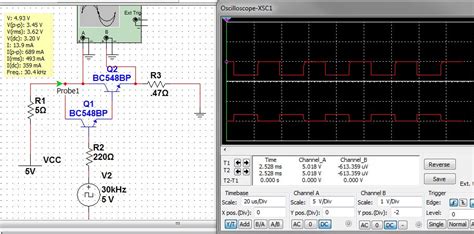

Current Sensing

To control the charging current and prevent overcharging, a current sensing mechanism is employed in the Li-Po charger circuit. This is typically achieved using a low-value shunt resistor in series with the charging path. The voltage drop across the shunt resistor is measured using an analog-to-digital converter (ADC) or a dedicated current sensing IC, allowing the microcontroller to monitor and regulate the charging current.

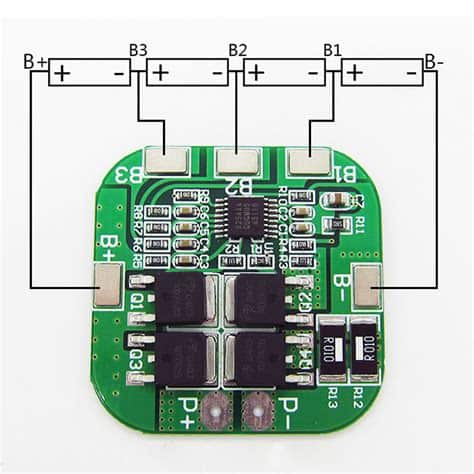

Battery Protection

Li-Po batteries require protection against overcharging, over-discharging, and short-circuits. A battery protection circuit is incorporated into the Li-Po charger circuit to ensure the safety of the battery. The protection circuit typically includes the following components:

- Over-voltage protection (OVP): Prevents the battery from being charged beyond 4.2V per cell.

- Under-voltage protection (UVP): Prevents the battery from being discharged below a certain threshold (usually 3.0V per cell) to avoid deep discharge.

- Over-current protection (OCP): Limits the charging and discharging current to prevent damage to the battery and charger circuit.

- Short-circuit protection (SCP): Disconnects the battery in case of a short-circuit to prevent catastrophic failure.

User Interface

A user interface is often incorporated into the Li-Po charger circuit to provide information and control options to the user. This can include:

- LED indicators: Display the charging status, battery level, and any error conditions.

- LCD or OLED display: Provides more detailed information, such as charging voltage, current, and time remaining.

- Buttons or switches: Allow the user to start/stop charging, select charging modes, or configure settings.

The user interface is controlled by the microcontroller and helps in monitoring and interacting with the charging process.

Charging Algorithms for Li-Po Batteries

To charge Li-Po batteries safely and efficiently, specific charging algorithms are employed in the charger circuit. The most common charging algorithm for Li-Po batteries is the Constant Current-Constant Voltage (CC-CV) method.

CC-CV Charging Algorithm

The CC-CV charging algorithm consists of two stages:

-

Constant Current (CC) Stage: In this stage, the charger supplies a constant current to the battery until the battery voltage reaches the charging voltage limit (4.2V per cell). The charging current is typically set to 1C (1 times the battery capacity) or lower, depending on the battery specifications and charging requirements.

-

Constant Voltage (CV) Stage: Once the battery voltage reaches the charging voltage limit, the charger switches to the CV stage. In this stage, the charger maintains a constant voltage of 4.2V per cell while gradually reducing the charging current. The charging process is considered complete when the charging current drops below a certain threshold (usually around 0.05C to 0.1C).

The CC-CV charging algorithm ensures that the battery is charged quickly during the CC stage and then gently topped off during the CV stage to maximize battery life and prevent overcharging.

Other Charging Algorithms

While the CC-CV algorithm is the most common, there are other charging algorithms that can be used for specific applications or battery types:

- Trickle Charging: A low-current charging method used to maintain a fully charged battery or slowly charge a deeply discharged battery.

- Pulse Charging: Applies short pulses of charging current followed by rest periods, which can help in reducing heat generation and improving charging efficiency.

- Fast Charging: Uses higher charging currents (>1C) to reduce charging time, but requires careful monitoring and control to prevent battery damage.

The choice of charging algorithm depends on the battery specifications, charging requirements, and the specific application.

Designing a Li-Po Charger Circuit

Now that we have covered the key components and charging algorithms, let’s discuss the steps involved in designing a Li-Po charger circuit.

Step 1: Determine Battery Specifications

Before starting the design process, it is essential to determine the specifications of the Li-Po battery that will be charged using the charger circuit. The important parameters to consider are:

- Battery voltage (number of cells in series)

- Battery capacity (in mAh or Ah)

- Maximum charging current

- Discharge cut-off voltage

These specifications will guide the selection of components and the design of the charging algorithm.

Step 2: Select the Microcontroller

Choose a microcontroller that meets the requirements of your Li-Po charger circuit. Consider factors such as:

- Number of ADC channels for voltage and current sensing

- PWM capabilities for controlling the charging current

- Sufficient I/O pins for interfacing with other components

- Available memory and processing power for implementing the charging algorithm

Popular choices for Li-Po charger circuits include Arduino, PIC, and STM32 microcontrollers.

Step 3: Design the Power Stage

The power stage of the Li-Po charger circuit consists of the voltage regulator and current sensing components. Design considerations for the power stage include:

- Selecting a suitable voltage regulator (e.g., buck converter) based on the input voltage range and required output voltage (4.2V per cell)

- Calculating the required current sensing shunt resistor value based on the maximum charging current and the ADC resolution of the microcontroller

- Implementing over-current protection using a current limiting circuit or a dedicated protection IC

Step 4: Implement Battery Protection

Incorporate battery protection features into the charger circuit to ensure the safety of the Li-Po battery. This includes:

- Over-voltage protection: Use a comparator or a dedicated protection IC to monitor the battery voltage and disconnect the charging circuit if the voltage exceeds 4.2V per cell.

- Under-voltage protection: Monitor the battery voltage during discharging and disconnect the load if the voltage drops below the specified cut-off voltage (usually 3.0V per cell).

- Short-circuit protection: Implement a fast-acting short-circuit protection mechanism, such as a fuse or a electronic switch, to disconnect the battery in case of a short-circuit.

Step 5: Design the User Interface

Design a user-friendly interface for the Li-Po charger circuit that provides information and control options to the user. Consider including:

- LED indicators for charging status, battery level, and error conditions

- LCD or OLED display for detailed information, such as charging voltage, current, and time remaining

- Buttons or switches for starting/stopping charging, selecting charging modes, or configuring settings

Ensure that the user interface is intuitive and easy to use, and provides clear feedback to the user.

Step 6: Implement the Charging Algorithm

Implement the chosen charging algorithm (e.g., CC-CV) in the microcontroller firmware. The firmware should:

- Monitor the battery voltage and charging current using the ADC channels

- Control the charging current and voltage using PWM signals or dedicated charging ICs

- Implement the state machine for the charging algorithm, transitioning between CC and CV stages as required

- Provide status updates and error handling through the user interface

Test the charging algorithm thoroughly to ensure that it operates safely and efficiently under various conditions.

Step 7: PCB Design and Assembly

Once the schematic design is complete, proceed with the PCB design and assembly of the Li-Po charger circuit. Consider the following:

- Use appropriate PCB layout techniques to minimize noise and ensure proper grounding

- Select components with suitable package sizes and ratings for the intended application

- Include necessary connectors for the battery, input power, and user interface

- Follow good soldering practices and perform thorough visual inspections and electrical tests before powering up the circuit

Safety Considerations

When designing and using Li-Po charger circuits, safety should always be a top priority. Li-Po batteries can be dangerous if mishandled or charged improperly. Follow these safety guidelines:

- Always use a charger designed specifically for Li-Po batteries and follow the manufacturer’s instructions carefully.

- Never leave a charging battery unattended and charge batteries in a fire-proof location away from flammable materials.

- Regularly inspect batteries for signs of damage, swelling, or leakage. Dispose of damaged batteries properly.

- Use appropriate battery management systems (BMS) for multi-cell Li-Po battery packs to ensure balanced charging and discharging.

- Implement adequate ventilation and cooling for the charger circuit and batteries to prevent overheating.

By adhering to these safety guidelines, you can minimize the risks associated with Li-Po batteries and ensure their safe and reliable operation.

Frequently Asked Questions (FAQ)

-

Q: Can I charge a Li-Po battery with a regular charger designed for other battery types?

A: No, it is essential to use a charger specifically designed for Li-Po batteries. Using a charger meant for other battery types can lead to overcharging, undercharging, or damage to the battery. -

Q: What is the maximum charging current for a Li-Po battery?

A: The maximum charging current for a Li-Po battery is typically specified by the manufacturer and is often expressed as a C-rate. A 1C charging rate means the battery can be charged at a current equal to its capacity. For example, a 1000mAh battery can be charged at 1A (1C) or lower. -

Q: How do I know when a Li-Po battery is fully charged?

A: When using the CC-CV charging algorithm, a Li-Po battery is considered fully charged when the charging current drops below a certain threshold (usually 0.05C to 0.1C) while the battery voltage is maintained at 4.2V per cell. -

Q: What should I do if my Li-Po battery is swollen or damaged?

A: If you notice any signs of swelling, damage, or leakage in a Li-Po battery, immediately stop using it and dispose of it properly. Do not attempt to charge or discharge a damaged battery as it can be dangerous and may lead to fire or explosion. -

Q: Can I charge multiple Li-Po batteries in parallel with a single charger?

A: It is not recommended to charge multiple Li-Po batteries in parallel with a single charger unless the charger is specifically designed for this purpose. Charging batteries in parallel can lead to uneven charging and potential safety hazards. It is best to charge each battery individually or use a charger with independent charging channels for multiple batteries.

Conclusion

Designing a reliable and safe Li-Po battery charger circuit requires a thorough understanding of battery characteristics, key components, charging algorithms, and safety considerations. By following the steps outlined in this article and adhering to best practices, you can create a robust Li-Po charger circuit that ensures optimal battery performance and longevity.

Remember to prioritize safety when working with Li-Po batteries and always use a charger designed specifically for this battery type. Regularly inspect your batteries for any signs of damage or degradation and dispose of them properly if necessary.

As technology continues to advance, new developments in Li-Po battery charging methods and circuit designs may emerge. Stay updated with the latest industry trends and best practices to ensure that your Li-Po charger circuits remain efficient, reliable, and safe.

By mastering the art of Li-Po battery charger circuit design, you can unlock the full potential of these powerful and versatile batteries in your projects and applications.

No responses yet