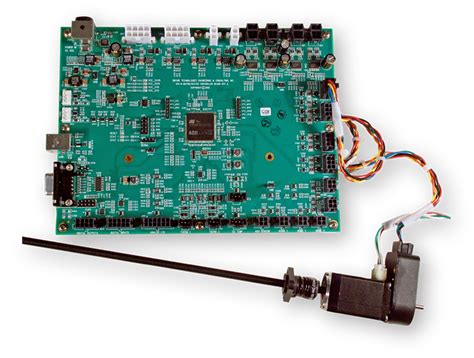

Introduction to Motor Controllers

A motor controller is an electronic device that regulates the performance of an electric motor. It controls the speed, torque, direction, and other parameters of the motor based on the desired application. Motor controllers are essential components in various industrial applications, such as robotics, automation, manufacturing, and transportation.

Types of Motor Controllers

There are several types of motor controllers, each designed for specific motor types and applications:

- DC Motor Controllers

- PWM (Pulse Width Modulation) Controllers

- Servo Controllers

-

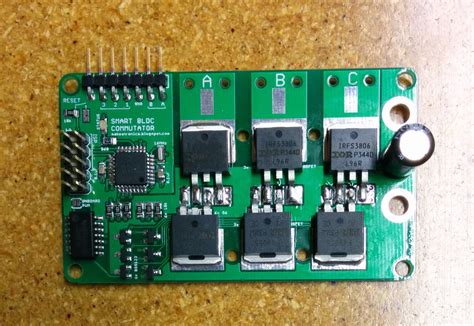

Brushless DC Motor Controllers

-

AC Motor Controllers

- Variable Frequency Drives (VFDs)

- Soft Starters

-

Intelligent Motor Controllers

-

Stepper Motor Controllers

Comparison of Motor Controller Types

| Controller Type | Motor Type | Key Features |

|---|---|---|

| PWM Controllers | DC Motors | Speed control, efficient, simple |

| Servo Controllers | Servo Motors | Precise position control, fast response |

| Brushless DC Controllers | BLDC Motors | High efficiency, low maintenance |

| Variable Frequency Drives | AC Induction Motors | Speed control, energy saving, soft starting |

| Soft Starters | AC Induction Motors | Smooth starting, reduced mechanical stress |

| Intelligent Controllers | Various | Programmable, networked, advanced features |

| Stepper Motor Controllers | Stepper Motors | Precise position control, open-loop operation |

How Motor Controllers Work

Motor controllers work by manipulating the electrical power supplied to the motor. They use various techniques to control the motor’s performance:

Pulse Width Modulation (PWM)

PWM is a common technique used in DC motor controllers. It involves rapidly switching the power supply on and off to control the average voltage delivered to the motor. By varying the duty cycle (the percentage of time the power is on), the controller can adjust the motor’s speed.

Variable Frequency Drives (VFDs)

VFDs are used to control AC induction motors. They convert the fixed-frequency AC power supply into a variable-frequency output. By changing the frequency and voltage, VFDs can control the motor’s speed and torque. VFDs also provide soft starting and stopping, energy savings, and improved motor efficiency.

Servo Control

Servo controllers are used with servo motors, which require precise position control. The controller continuously monitors the motor’s position using an encoder or resolver feedback. It compares the actual position with the desired position and adjusts the motor’s power accordingly to minimize the error.

Motor Controller Applications

Motor controllers find applications in various industries and sectors:

Industrial Automation

In manufacturing and production lines, motor controllers are used to control conveyor belts, robotic arms, CNC machines, and other automated equipment. They enable precise control, synchronization, and coordination of multiple motors for efficient and reliable operations.

Robotics

Motor controllers are essential components in robotic systems. They control the motors that drive the robot’s joints, wheels, or arms. Controllers enable precise position control, speed regulation, and coordinated motion for tasks such as pick-and-place, welding, painting, and assembly.

Electric Vehicles

In electric vehicles (EVs), motor controllers manage the power flow between the battery and the electric motors. They control the motor’s speed, torque, and regenerative braking. Advanced controllers also incorporate features like traction control, battery management, and energy optimization.

HVAC Systems

Motor controllers are used in heating, ventilation, and air conditioning (HVAC) systems to control fans, compressors, and pumps. VFDs are commonly used to regulate the speed of the motors based on the cooling or heating demand, resulting in energy savings and improved comfort.

Selecting the Right Motor Controller

When choosing a motor controller for your application, consider the following factors:

-

Motor Type: Ensure that the controller is compatible with the type of motor you are using (DC, AC, servo, stepper).

-

Power Rating: Select a controller that can handle the rated power and current of your motor.

-

Control Features: Consider the control features you require, such as speed control, position control, soft starting, or programmability.

-

Communication Interfaces: If you need to integrate the controller with other systems or devices, check for compatible communication interfaces (e.g., RS-232, RS-485, Ethernet, CAN).

-

Environmental Factors: Consider the operating environment of the controller, including temperature range, humidity, vibration, and dust/debris exposure.

Motor Controller Programming and Configuration

Most modern motor controllers offer programming and configuration options to customize their behavior for specific applications. This can be done through dedicated software tools, programming languages, or user interfaces.

Programming Languages

Some common programming languages used for motor controller configuration include:

- Ladder Logic: A graphical programming language commonly used in PLC (Programmable Logic Controller) programming.

- C/C++: High-level programming languages used for more complex and customized control algorithms.

- BASIC: A simple programming language often used in smaller or older controllers.

Configuration Software

Many motor controller manufacturers provide proprietary software tools for configuring and monitoring their controllers. These tools typically offer a user-friendly interface for setting parameters, tuning performance, and monitoring real-time data.

User Interfaces

Some motor controllers feature built-in user interfaces, such as LCD displays and keypads, for local configuration and monitoring. These interfaces allow operators to adjust settings, view status information, and perform basic troubleshooting without the need for additional software or devices.

Motor Controller Maintenance and Troubleshooting

Regular maintenance and troubleshooting are essential to ensure the reliable and efficient operation of motor controllers. Some key aspects to consider:

-

Periodic Inspection: Regularly inspect the controller for any signs of physical damage, loose connections, or overheating.

-

Firmware Updates: Keep the controller’s firmware up to date to ensure optimal performance and compatibility with other systems.

-

Parameter Backup: Regularly backup the controller’s configuration settings to avoid data loss in case of failure or maintenance.

-

Troubleshooting: Familiarize yourself with common troubleshooting techniques, such as checking power supply, verifying wiring connections, and monitoring diagnostic indicators or error codes.

Frequently Asked Questions (FAQ)

- What is the difference between a motor controller and a drive?

-

A motor controller is a general term for a device that controls the operation of a motor, while a drive specifically refers to a device that controls the speed, torque, and direction of a motor. Drives are a type of motor controller.

-

Can a motor controller be used with any type of motor?

-

No, motor controllers are designed for specific types of motors. It is important to select a controller that is compatible with the motor type (DC, AC, servo, stepper) and meets the power and control requirements.

-

How does a motor controller improve energy efficiency?

-

Motor controllers can improve energy efficiency by optimizing the power delivered to the motor based on the load requirements. Techniques like variable frequency drives and soft starting reduce energy waste and improve overall system efficiency.

-

What is the role of feedback in motor control?

-

Feedback, such as position or speed feedback from encoders or resolvers, is used in closed-loop control systems. The controller compares the actual motor performance with the desired setpoint and adjusts the control output accordingly to minimize errors and maintain precise control.

-

How do I select the appropriate motor controller for my application?

- When selecting a motor controller, consider factors such as motor type, power rating, control features, communication interfaces, and environmental requirements. Consult the controller manufacturer’s documentation and application guides to ensure proper selection and sizing.

Conclusion

Motor controllers play a crucial role in the operation and performance of electric motors in various applications. Understanding the different types of controllers, their working principles, and their applications is essential for designing efficient and reliable motor-driven systems. Proper selection, programming, maintenance, and troubleshooting of motor controllers ensure optimal performance, energy efficiency, and long-term reliability.

Word count: 1,287 words

No responses yet