Introduction

In the world of Electrical Engineering, two commonly used devices are potentiometers and rheostats. While both are variable resistors, they serve different purposes and have distinct characteristics. Understanding the differences between these two components is crucial for anyone working with electrical circuits or designing electronic systems.

In this comprehensive article, we will delve into the key differences between potentiometers and rheostats, exploring their construction, functionality, applications, and more. By the end of this article, you will have a clear understanding of when to use a potentiometer or a rheostat in your projects.

What is a Potentiometer?

A potentiometer, often referred to as a “pot,” is a three-terminal variable resistor. It consists of a resistive element with a sliding contact (wiper) that can be moved along the element to vary the resistance between the wiper and the two end terminals.

Construction of a Potentiometer

A potentiometer typically consists of the following components:

-

Resistive Element: A strip of resistive material, such as carbon or cermet, is used as the main resistive element. The resistance value of the potentiometer is determined by the length and composition of this element.

-

Wiper: A sliding contact, known as the wiper, is connected to a shaft or knob. As the shaft is rotated or the knob is turned, the wiper moves along the resistive element, making contact at different points.

-

Terminals: A potentiometer has three terminals – two fixed end terminals and a wiper terminal. The end terminals are connected to the ends of the resistive element, while the wiper terminal is connected to the sliding contact.

How a Potentiometer Works

A potentiometer works by dividing the input voltage across its resistive element. As the wiper moves along the element, it taps off a portion of the voltage, creating a variable output voltage between the wiper and one of the end terminals.

The position of the wiper determines the ratio of the resistance between the wiper and the two end terminals. This ratio, in turn, determines the output voltage. By adjusting the position of the wiper, you can control the output voltage within the range of the input voltage.

Types of Potentiometers

Potentiometers come in various types, each with its own characteristics and applications:

-

Linear Potentiometer: In a linear potentiometer, the resistance changes linearly with the rotation of the shaft. These are commonly used for volume control, dimming, and position sensing.

-

Logarithmic Potentiometer: Logarithmic potentiometers have a non-linear resistance curve, where the resistance changes logarithmically with the rotation. They are often used in audio applications for volume control, as they better match the human perception of sound.

-

Rotary Potentiometer: Rotary potentiometers have a circular resistive element and a rotating shaft. They are widely used for adjusting settings, such as volume control or fan speed.

-

Slider Potentiometer: Slider potentiometers have a linear resistive element and a sliding wiper that moves along a straight path. They are commonly used for audio mixing consoles, graphic equalizers, and lighting controls.

Applications of Potentiometers

Potentiometers find applications in various fields, including:

-

Audio Systems: Potentiometers are used for volume control, tone control, and audio mixing in audio equipment like amplifiers, mixers, and sound systems.

-

Lighting Control: Dimmer switches and lighting controllers often use potentiometers to adjust the brightness of lights.

-

Position Sensing: Potentiometers can be used as position sensors, where the position of the wiper indicates the position of a mechanical component, such as a throttle or a control surface in an aircraft.

-

Motor Speed Control: Potentiometers can be used to control the speed of DC motors by varying the voltage applied to the motor.

-

Instrumentation: In measurement and instrumentation systems, potentiometers are used for calibration, offset adjustment, and signal conditioning.

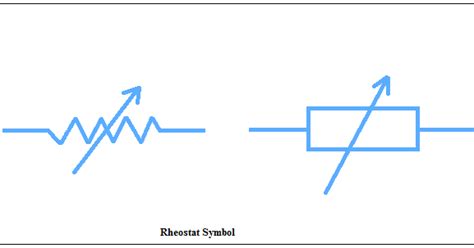

What is a Rheostat?

A rheostat is a two-terminal variable resistor that is used to control the current flow in a circuit by varying its resistance. Unlike a potentiometer, a rheostat does not have a wiper terminal and is designed to handle higher power dissipation.

Construction of a Rheostat

A rheostat typically consists of the following components:

-

Resistive Element: Similar to a potentiometer, a rheostat has a resistive element made of materials like wire-wound nichrome or ceramic. The resistance value of the rheostat depends on the length and composition of the resistive element.

-

Sliding Contact: A sliding contact, often made of metal, moves along the resistive element to vary the resistance. The position of the sliding contact determines the effective resistance of the rheostat.

-

Terminals: A rheostat has two terminals – one connected to the end of the resistive element and the other connected to the sliding contact.

How a Rheostat Works

A rheostat works by varying the effective length of the resistive element in the circuit. As the sliding contact moves along the resistive element, it changes the amount of resistance in the circuit, thereby controlling the current flow.

When the sliding contact is at one end of the resistive element, the rheostat offers minimum resistance, allowing maximum current flow. As the contact moves towards the other end, the resistance increases, reducing the current flow. When the contact reaches the opposite end, the rheostat offers maximum resistance, minimizing the current flow.

Types of Rheostats

Rheostats are classified based on their construction and application:

-

Wire-Wound Rheostat: Wire-wound rheostats use a coiled wire as the resistive element. They are capable of handling high power dissipation and are often used in high-current applications.

-

Ceramic Rheostat: Ceramic rheostats use a ceramic substrate with a resistive coating as the resistive element. They are compact, have a high power rating, and are suitable for high-temperature applications.

-

Sliding Rheostat: Sliding rheostats have a linear resistive element and a sliding contact that moves along a straight path. They are used for applications that require precise control over the resistance.

-

Rotary Rheostat: Rotary rheostats have a circular resistive element and a rotating contact. They are commonly used for adjusting the speed of motors or dimming lights.

Applications of Rheostats

Rheostats find applications in various areas, including:

-

Motor Speed Control: Rheostats are used to control the speed of DC motors by varying the current supplied to the motor windings.

-

Lighting Control: Rheostats are used in dimmer circuits to control the brightness of incandescent lamps or LED lights.

-

Power Control: Rheostats are used to control the power dissipation in electrical heating elements, such as in electric stoves or industrial heating systems.

-

Current Limiting: Rheostats can be used as current-limiting devices to protect sensitive electronic components from excessive current flow.

-

Testing and Calibration: Rheostats are used in testing and calibration equipment to provide variable resistance for accurate measurements.

Potentiometer vs Rheostat: Key Differences

Now that we have a basic understanding of potentiometers and rheostats, let’s summarize the key differences between them:

| Feature | Potentiometer | Rheostat |

|---|---|---|

| Terminals | Three (two end terminals and a wiper terminal) | Two (one end terminal and a sliding contact terminal) |

| Functionality | Voltage divider, provides a variable output voltage | Variable resistor, controls current flow |

| Power Rating | Typically low power rating | Capable of handling higher power dissipation |

| Applications | Audio systems, lighting control, position sensing, instrumentation | Motor speed control, power control, current limiting |

| Adjustability | Provides precise adjustment of output voltage | Provides variable resistance, but not as precise as a potentiometer |

| Wiper | Has a wiper terminal for tapping off a portion of the input voltage | No wiper terminal, sliding contact varies the effective resistance |

FAQ

-

Can a potentiometer be used as a rheostat?

Yes, a potentiometer can be used as a rheostat by connecting one end terminal and the wiper terminal, effectively using only two terminals. However, it is not recommended, as potentiometers are not designed to handle high power dissipation like rheostats. -

What happens if I connect the wrong terminals on a potentiometer or rheostat?

Connecting the wrong terminals can lead to incorrect functionality or even damage the component. Always refer to the datasheet or schematic diagram to ensure proper connections. -

How do I choose the right potentiometer or rheostat for my application?

When selecting a potentiometer or rheostat, consider factors such as the required resistance range, power rating, linearity, and physical size. Consult the component’s datasheet and match it with your application requirements. -

Can I replace a potentiometer with a rheostat in a circuit?

It depends on the specific application. If the circuit requires a voltage divider functionality, a potentiometer is necessary. However, if the circuit only needs variable resistance for current control, a rheostat can be used. -

Are there any special considerations when using potentiometers or rheostats?

Yes, consider the power dissipation capabilities of the component and ensure proper heat dissipation if necessary. Also, be aware of the mechanical wear and tear on the sliding contacts, as they can affect the long-term reliability of the component.

Conclusion

Potentiometers and rheostats are both variable resistors, but they serve different purposes in electrical circuits. Potentiometers are three-terminal devices used as voltage dividers, providing a variable output voltage. They find applications in audio systems, lighting control, position sensing, and instrumentation.

On the other hand, rheostats are two-terminal devices used to control current flow by varying the resistance. They are capable of handling higher power dissipation and are commonly used in motor speed control, power control, and current limiting applications.

Understanding the differences between potentiometers and rheostats is essential for selecting the appropriate component for your specific application. By considering factors such as functionality, power rating, and adjustability, you can make an informed decision and ensure the optimal performance of your electrical circuits.

No responses yet