Introduction to IoT and Additive Manufacturing

The Internet of Things (IoT) and Additive Manufacturing (AM), also known as 3D printing, are two rapidly evolving technologies that are transforming the world of electronics. IoT refers to the interconnected network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, and network connectivity, which enables these objects to collect and exchange data. On the other hand, AM is a process of creating three-dimensional objects by depositing materials layer by layer based on a digital model.

The convergence of IoT and AM (IoT-AM) is creating new opportunities for the electronics industry, enabling the development of intelligent, connected, and customizable devices. This article explores the potential of IoT-AM in shaping the future of electronics, discussing its applications, benefits, challenges, and future prospects.

The Role of IoT in Electronics

IoT has already made significant strides in the electronics industry, with connected devices becoming increasingly prevalent in our daily lives. From smart homes and wearables to industrial sensors and autonomous vehicles, IoT is enabling a wide range of applications that rely on real-time data collection, analysis, and communication.

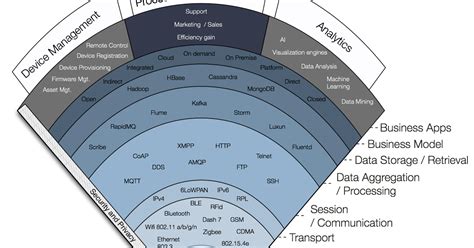

IoT Architecture and Components

The IoT architecture consists of four main components:

- Sensors and Actuators: These are the devices that collect data from the environment or perform actions based on received commands.

- Connectivity: IoT devices are connected to the internet or other networks through various communication protocols, such as Wi-Fi, Bluetooth, or cellular networks.

- Data Processing: The collected data is processed and analyzed using edge computing, cloud computing, or a combination of both.

- User Interface: The processed data is presented to users through various interfaces, such as mobile apps, web portals, or voice assistants.

Benefits of IoT in Electronics

IoT offers several benefits to the electronics industry, including:

- Enhanced Efficiency: IoT enables real-time monitoring and control of devices, allowing for optimization of energy consumption, predictive maintenance, and improved overall efficiency.

- Improved User Experience: Connected devices offer personalized and convenient experiences to users, such as remote control, voice-activated commands, and automated tasks.

- Data-Driven Insights: IoT generates vast amounts of data that can be analyzed to gain insights into user behavior, product performance, and market trends, enabling data-driven decision-making.

- New Business Models: IoT enables new business models, such as product-as-a-service, where companies can offer subscription-based access to connected devices and services.

Additive Manufacturing in Electronics

Additive Manufacturing, or 3D printing, is revolutionizing the way electronics are designed, prototyped, and manufactured. AM allows for the creation of complex geometries, customized designs, and rapid prototyping, which traditional manufacturing methods may find challenging or impossible to achieve.

AM Technologies for Electronics

There are several AM technologies suitable for electronics manufacturing, including:

- Fused Deposition Modeling (FDM): FDM is the most common and affordable AM technology, which works by extruding thermoplastic materials layer by layer to create 3D objects. FDM is suitable for creating housings, enclosures, and other non-conductive components.

- Stereolithography (SLA): SLA uses a laser to cure and harden liquid photopolymer resin layer by layer. SLA offers high resolution and smooth surface finishes, making it suitable for creating detailed and intricate electronic components.

- Selective Laser Sintering (SLS): SLS uses a laser to sinter powdered materials, such as nylon or metal, into a solid 3D object. SLS is suitable for creating functional electronic components, such as antennas, sensors, and circuit boards.

- Direct Write (DW): DW is a process of directly depositing conductive inks or pastes onto substrates to create electronic circuits and components. DW enables the creation of flexible and stretchable electronics, as well as the integration of electronics into 3D-printed structures.

Benefits of AM in Electronics

AM offers several benefits to the electronics industry, including:

- Rapid Prototyping: AM enables quick and cost-effective prototyping of electronic components and devices, reducing the time and cost associated with traditional prototyping methods.

- Customization: AM allows for the creation of customized and personalized electronic devices, tailored to specific user needs and preferences.

- Complexity: AM can create complex geometries and internal structures that are difficult or impossible to achieve with traditional manufacturing methods, enabling new design possibilities for electronic components.

- Sustainability: AM can reduce material waste and energy consumption compared to traditional manufacturing methods, contributing to a more sustainable electronics industry.

The Convergence of IoT and AM

The convergence of IoT and AM is creating new opportunities for the electronics industry, enabling the development of intelligent, connected, and customizable devices. IoT-AM combines the benefits of both technologies, allowing for the creation of smart, responsive, and adaptable electronic systems.

IoT-AM Applications

IoT-AM has a wide range of applications across various industries, including:

- Wearables: IoT-AM enables the creation of personalized and intelligent wearable devices, such as smartwatches, fitness trackers, and medical monitors, that can collect and analyze user data in real-time.

- Smart Homes: IoT-AM can be used to create customized and connected home automation devices, such as smart locks, thermostats, and lighting systems, that can be controlled remotely and adapt to user preferences.

- Industrial IoT: IoT-AM can be applied in industrial settings to create intelligent and connected sensors, actuators, and control systems for process monitoring, predictive maintenance, and optimization.

- Healthcare: IoT-AM can revolutionize healthcare by enabling the creation of personalized medical devices, implants, and prosthetics that can monitor patient health and adapt to their specific needs.

Challenges and Considerations

Despite the numerous benefits, IoT-AM also presents some challenges and considerations, including:

- Security and Privacy: IoT devices are vulnerable to cyber-attacks and data breaches, requiring robust security measures and privacy protection.

- Interoperability: Ensuring interoperability between different IoT devices and systems is crucial for seamless integration and data exchange.

- Scalability: As the number of connected devices grows, IoT-AM systems need to be scalable to handle the increasing volume of data and network traffic.

- Skill Gap: The adoption of IoT-AM requires a skilled workforce with expertise in both IoT and AM technologies, which may be a challenge for some organizations.

Future Prospects and Research Directions

The convergence of IoT and AM presents a promising future for the electronics industry, with numerous research directions and opportunities for innovation.

Emerging Trends and Technologies

Some of the emerging trends and technologies in IoT-AM include:

- 5G Networks: The deployment of 5G networks will enable faster, more reliable, and low-latency connectivity for IoT devices, enhancing their performance and enabling new applications.

- Edge Computing: Edge computing brings data processing closer to the source, reducing latency and enabling real-time decision-making for IoT-AM systems.

- Artificial Intelligence (AI): The integration of AI with IoT-AM will enable intelligent, self-learning, and adaptive electronic systems that can optimize their performance and user experience.

- Digital Twins: Digital twins, which are virtual replicas of physical devices, can be used in IoT-AM to simulate, monitor, and optimize the performance of electronic systems throughout their lifecycle.

Research Directions and Opportunities

Some of the key research directions and opportunities in IoT-AM include:

- Materials and Processes: Developing new materials and processes for AM that are specifically suited for electronic applications, such as conductive and functional materials.

- Design and Simulation: Advancing design and simulation tools for IoT-AM that can optimize the performance, reliability, and manufacturability of electronic devices.

- Security and Privacy: Developing robust security and privacy solutions for IoT-AM systems, such as blockchain-based authentication and secure data management.

- Energy Efficiency: Investigating energy-efficient approaches for IoT-AM, such as low-power sensors, energy harvesting, and power management techniques.

Frequently Asked Questions (FAQ)

-

What is the difference between IoT and AM?

IoT refers to the interconnected network of physical devices, vehicles, home appliances, and other items embedded with electronics, software, sensors, and network connectivity, which enables these objects to collect and exchange data. AM, or 3D printing, is a process of creating three-dimensional objects by depositing materials layer by layer based on a digital model. -

What are the benefits of combining IoT and AM in electronics?

Combining IoT and AM in electronics offers several benefits, such as enabling the development of intelligent, connected, and customizable devices, allowing for rapid prototyping and personalization, and enabling new design possibilities and applications. -

What are some examples of IoT-AM applications in electronics?

Some examples of IoT-AM applications in electronics include wearable devices, smart home automation systems, industrial IoT sensors and control systems, and personalized medical devices and implants. -

What are the challenges and considerations in adopting IoT-AM in electronics?

Some of the challenges and considerations in adopting IoT-AM in electronics include ensuring security and privacy, achieving interoperability between different devices and systems, scaling the infrastructure to handle increasing data and network traffic, and addressing the skill gap in the workforce. -

What are some of the emerging trends and research directions in IoT-AM for electronics?

Some of the emerging trends and research directions in IoT-AM for electronics include the integration of 5G networks, edge computing, artificial intelligence, and digital twins, as well as the development of new materials and processes, advanced design and simulation tools, robust security and privacy solutions, and energy-efficient approaches.

Conclusion

The convergence of IoT and AM is transforming the electronics industry, enabling the development of intelligent, connected, and customizable devices that can adapt to user needs and optimize their performance. While IoT-AM presents numerous opportunities and benefits, it also comes with challenges and considerations that need to be addressed, such as security, interoperability, scalability, and skill gaps.

As the adoption of IoT-AM continues to grow, it is crucial for organizations to invest in research and development, collaborate with stakeholders across the value chain, and foster a skilled workforce to unlock the full potential of these technologies. By embracing IoT-AM, the electronics industry can create innovative, sustainable, and user-centric solutions that will shape the future of our connected world.

No responses yet