Introduction to RF-Digital Layout

When designing a printed circuit board (PCB) that incorporates both radio frequency (RF) and digital circuits, careful consideration must be given to the layout to ensure optimal performance and minimize interference between the two types of circuits. RF circuits are sensitive to noise and interference, while digital circuits generate high-frequency noise that can disrupt RF signals. This article will explore the best practices and techniques for arranging a board with both RF and digital circuits to achieve a successful RF-Digital layout.

Understanding the Challenges of RF-Digital Integration

Noise and Interference

One of the primary challenges in RF-Digital layout is managing noise and interference. Digital circuits generate high-frequency noise due to their switching activity, which can couple into the sensitive RF circuits and degrade their performance. This noise can manifest as electromagnetic interference (EMI) or crosstalk between the digital and RF sections of the board.

Signal Integrity

Maintaining signal integrity is crucial in both RF and digital circuits. However, the requirements for each type of circuit differ. RF circuits require careful control of impedance, while digital circuits need clean, sharp edges for accurate data transmission. Balancing these requirements can be challenging when both types of circuits are present on the same board.

Power Supply Considerations

RF and digital circuits often have different power supply requirements. RF circuits typically require a clean, low-noise power supply to maintain signal quality, while digital circuits can tolerate some level of power supply noise. Providing separate power supplies or proper filtering is essential to ensure each section of the board receives the appropriate power.

Best Practices for RF-Digital Layout

Partitioning the Board

One of the most effective techniques for successful RF-Digital layout is partitioning the board into distinct RF and digital sections. This involves physically separating the RF and digital circuits as much as possible to minimize crosstalk and interference. By creating a clear boundary between the two sections, you can better control the interaction between them.

Grounding and Shielding

Proper grounding and shielding are critical in RF-Digital layout. Use separate ground planes for the RF and digital sections of the board, and connect them at a single point to prevent ground loops. Employ shielding techniques, such as metal cans or shielding walls, to isolate the RF circuits from the digital noise. Shielding helps contain the electromagnetic fields generated by the digital circuits and prevents them from interfering with the RF signals.

Component Placement

Strategic component placement is essential for minimizing interference and ensuring optimal performance. Place the RF components as far away from the digital components as possible to reduce coupling. Orient the RF components to minimize the coupling of digital noise into the RF signal path. Additionally, keep the RF and digital traces as short as possible to reduce the potential for interference.

Trace Routing

When routing traces on the board, follow these guidelines to minimize interference and maintain signal integrity:

– Keep RF traces as short and direct as possible to minimize losses and reflections.

– Avoid running RF traces parallel to digital traces to reduce crosstalk.

– Use controlled impedance traces for RF signals to ensure proper impedance matching.

– Provide adequate spacing between RF and digital traces to minimize coupling.

– Use ground planes or guard traces to isolate RF traces from digital noise.

Decoupling and Filtering

Implementing proper decoupling and filtering techniques is crucial for maintaining signal integrity and reducing noise in RF-Digital layouts. Use decoupling capacitors near the power pins of both RF and digital components to provide a low-impedance path for high-frequency noise. Place the decoupling capacitors as close to the components as possible to maximize their effectiveness.

For sensitive RF circuits, consider using RF chokes or ferrite beads to filter out high-frequency noise from the power supply. These components help attenuate the noise and prevent it from reaching the RF circuitry.

Impedance Matching

Impedance matching is critical in RF circuits to ensure maximum power transfer and minimize reflections. When routing RF traces, ensure that the characteristic impedance of the traces matches the impedance of the RF components and connectors. This can be achieved by controlling the trace width, thickness, and spacing relative to the ground plane.

Layout Techniques for Specific RF-Digital Scenarios

RF Transmitter and Digital Control Circuitry

When designing a board with an RF transmitter and digital control circuitry, follow these guidelines:

– Place the RF transmitter section as far away from the digital control circuitry as possible.

– Use separate power supplies or filtering for the RF transmitter and digital control sections.

– Employ shielding techniques to isolate the RF transmitter from the digital noise.

– Route the RF output trace away from the digital traces and provide adequate spacing.

RF Receiver and Digital Signal Processing

For boards incorporating an RF receiver and digital signal processing, consider these techniques:

– Locate the RF receiver section away from the digital signal processing circuitry.

– Use separate ground planes for the RF and digital sections, connected at a single point.

– Implement proper decoupling and filtering for the RF receiver power supply.

– Route the RF input trace away from the digital traces and provide shielding if necessary.

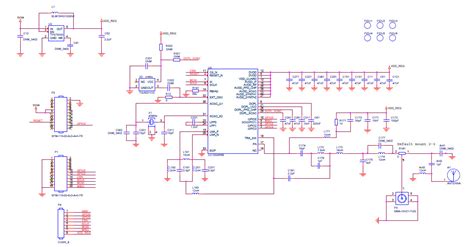

Mixed-Signal RF-Digital ICs

When working with mixed-signal RF-Digital ICs, such as transceivers or system-on-chip (SoC) devices, follow these guidelines:

– Place the mixed-signal IC close to the RF connectors or antenna to minimize RF trace lengths.

– Provide separate power supplies or filtering for the RF and digital sections of the IC.

– Use controlled impedance traces for the RF signals to and from the IC.

– Implement proper grounding and decoupling techniques for the IC.

Testing and Verification

Once the RF-Digital layout is complete, thorough testing and verification are necessary to ensure proper functionality and performance. Consider the following steps:

-

Visual Inspection: Perform a visual inspection of the assembled board to check for any manufacturing defects or assembly issues.

-

Power-Up Test: Conduct a power-up test to verify that the board powers up correctly and there are no short circuits or excessive current draw.

-

Functional Testing: Perform functional testing to ensure that both the RF and digital sections of the board operate as intended. This may involve testing the RF performance parameters, such as output power, sensitivity, and spectral purity, as well as verifying the digital functionality.

-

EMI/EMC Testing: Conduct electromagnetic interference (EMI) and electromagnetic compatibility (EMC) testing to ensure that the board meets the required regulatory standards. This testing helps identify any issues related to radiated or conducted emissions and susceptibility to external interference.

-

Signal Integrity Analysis: Perform signal integrity analysis using oscilloscopes or specialized tools to verify the quality of the RF and digital signals. Check for any signal distortion, reflections, or crosstalk that may impact performance.

-

Thermal Analysis: Conduct thermal analysis to ensure that the board operates within the specified temperature range and there are no hotspots or excessive thermal gradients that could affect reliability.

By thoroughly testing and verifying the RF-Digital layout, you can identify and address any issues early in the development process, ensuring a robust and reliable final product.

Conclusion

Arranging a board with both RF and digital circuits requires careful consideration and adherence to best practices to ensure optimal performance and minimize interference. By partitioning the board, implementing proper grounding and shielding, strategic component placement, and following trace routing guidelines, you can successfully integrate RF and digital circuits on the same board.

Remember to consider the specific requirements of your RF-Digital scenario, whether it involves an RF transmitter, receiver, or mixed-signal IC. Thorough testing and verification are essential to validate the design and ensure that the board meets the desired performance and reliability standards.

By following these guidelines and techniques, you can overcome the challenges of RF-Digital integration and create a well-functioning board that leverages the strengths of both RF and digital technologies.

Frequently Asked Questions (FAQ)

-

Q: What is the main challenge in RF-Digital layout?

A: The main challenge in RF-Digital layout is managing noise and interference between the sensitive RF circuits and the high-frequency noise generated by the digital circuits. -

Q: How can I minimize crosstalk between RF and digital sections of the board?

A: To minimize crosstalk, you can physically separate the RF and digital sections, use separate ground planes, implement shielding techniques, and route traces strategically to reduce coupling. -

Q: Why is impedance matching important in RF circuits?

A: Impedance matching is important in RF circuits to ensure maximum power transfer and minimize reflections. Mismatched impedances can lead to signal loss and degraded performance. -

Q: What are the key considerations when placing components in an RF-Digital layout?

A: When placing components, consider the following: - Place RF components far away from digital components to reduce coupling.

- Orient RF components to minimize the coupling of digital noise into the RF signal path.

-

Keep RF and digital traces as short as possible to reduce interference.

-

Q: How can I verify the performance of my RF-Digital layout?

A: To verify the performance of your RF-Digital layout, conduct thorough testing, including visual inspection, power-up tests, functional testing, EMI/EMC testing, signal integrity analysis, and thermal analysis. These tests help identify any issues and ensure the board meets the required performance and reliability standards.

No responses yet