Potential Health Risks

One of the primary concerns when it comes to PCB etching at home is the potential health risks involved. The process often requires the use of hazardous chemicals, such as ferric chloride or cupric chloride, which can be harmful if not handled properly.

Exposure to Harmful Chemicals

Etching solutions used in the PCB etching process can cause skin irritation, respiratory issues, and even more severe health problems if ingested or inhaled. It’s essential to wear appropriate protective gear, such as gloves, goggles, and a respirator, to minimize exposure to these chemicals.

Proper Ventilation Required

Working with etching chemicals also requires adequate ventilation to prevent the buildup of harmful fumes. Without proper ventilation, you risk exposing yourself and others in your household to these dangerous vapors.

Environmental Concerns

Another significant disadvantage of PCB etching at home is the potential impact on the environment. Improper disposal of etching chemicals and waste materials can lead to serious environmental consequences.

Proper Disposal of Chemicals

Etching solutions and other chemicals used in the process must be disposed of correctly to avoid contaminating soil, water, and wildlife. Many municipalities have specific guidelines for disposing of hazardous waste, which may require special handling and additional costs.

Waste Management

In addition to the chemicals, PCB etching generates waste materials such as copper clippings and used substrates. These materials must also be disposed of responsibly to minimize their environmental impact.

Time-Consuming Process

PCB etching at home can be a time-consuming process, especially for beginners or those working on complex designs.

Preparation and Setup

Before you can begin etching, you need to prepare your design, print the circuit onto a transparent film, and transfer it onto the copper-clad board. This preparation stage can take a significant amount of time, particularly if you’re new to the process.

Etching and Cleaning

The actual etching process, which involves submerging the board in the etching solution and agitating it to remove the unwanted copper, can also be time-consuming. After etching, you’ll need to clean the board thoroughly and remove any remaining resist material.

Limited Design Capabilities

When etching PCBs at home, you may face limitations in terms of design capabilities compared to professionally manufactured boards.

Minimum Feature Size

Home etching setups may not be able to achieve the same level of detail and precision as professional manufacturing processes. This limitation can restrict your ability to create designs with very fine traces or small components.

Single-Sided Boards

Most home etching processes are limited to producing single-sided boards, which means that all components and traces must be placed on one side of the board. This limitation can make it more challenging to create complex or compact designs.

Higher Material Costs

While PCB etching at home can be cost-effective for small-scale projects, material costs can quickly add up, especially if you need to make multiple revisions or prototypes.

Copper-Clad Boards

The copper-clad boards used for etching can be relatively expensive, particularly if you’re working with high-quality substrates or larger board sizes.

Etching Chemicals

Etching solutions and other required chemicals can also be costly, and you may need to purchase them in larger quantities than necessary for your project, leading to waste and additional expenses.

Quality Control Issues

Achieving consistent quality when etching PCBs at home can be challenging, as many variables can affect the final result.

Inconsistent Etching

Factors such as temperature, agitation, and the concentration of the etching solution can all impact the quality and consistency of your etched boards. Achieving uniform etching across the entire board can be difficult, especially for larger designs.

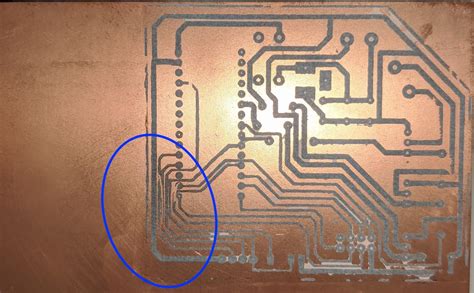

Defects and Errors

Home-etched PCBs are more prone to defects and errors, such as over-etching, under-etching, or incomplete resist removal. These issues can lead to poor electrical connections or even non-functional boards.

Limited Scalability

PCB etching at home is generally not suitable for large-scale production or commercial applications.

Manual Labor

The manual nature of home etching makes it impractical for producing large quantities of boards, as the process can be time-consuming and labor-intensive.

Inconsistent Results

As mentioned earlier, achieving consistent quality across multiple boards can be challenging with home etching, making it unsuitable for applications that require reliable and uniform performance.

Troubleshooting and Debugging

When issues arise with home-etched PCBs, troubleshooting and debugging can be more difficult compared to professionally manufactured boards.

Identifying Problems

Determining the root cause of issues with a home-etched board can be challenging, as defects may be related to the etching process, component placement, or other factors.

Limited Resources

Unlike professional PCB manufacturers, who have access to advanced testing and debugging equipment, home enthusiasts may have limited resources for identifying and resolving issues with their boards.

Space and Equipment Requirements

Setting up a PCB etching workspace at home requires dedicated space and specialized equipment, which may not be feasible for everyone.

Workspace Constraints

You’ll need a designated area to set up your etching station, store chemicals, and work on your projects. This space should be well-ventilated and isolated from living areas to minimize the risk of exposure to harmful substances.

Equipment Costs

In addition to the materials needed for each project, you’ll need to invest in equipment such as a UV exposure unit, etching tanks, and safety gear. These initial costs can add up, especially if you’re just starting out.

Lack of Professional Support

When etching PCBs at home, you may not have access to the same level of professional support and resources as you would when working with a professional PCB manufacturer.

Limited Expertise

As a hobbyist, you may not have the same level of expertise and knowledge as professional PCB designers and manufacturers. This lack of experience can make it more difficult to overcome challenges and achieve optimal results.

No Warranty or Guarantee

Unlike professionally manufactured PCBs, which often come with warranties or guarantees, home-etched boards are solely your responsibility. If something goes wrong, you’ll need to troubleshoot and fix the issue on your own.

Frequently Asked Questions (FAQ)

-

Is PCB etching at home safe?

PCB etching at home can be safe if proper precautions are taken, such as wearing protective gear, ensuring adequate ventilation, and handling chemicals responsibly. However, there are inherent risks involved, and it’s essential to be aware of the potential hazards before starting. -

Can I etch complex, multi-layered PCBs at home?

Etching complex, multi-layered PCBs at home can be challenging and may require more advanced equipment and techniques. Most home etching setups are better suited for simpler, single-sided designs. -

How much does it cost to set up a PCB etching workspace at home?

The cost of setting up a PCB etching workspace at home can vary depending on the equipment and materials you choose. Basic setups can start from around $100, while more advanced setups can cost several hundred dollars or more. -

Are there any legal requirements for disposing of etching chemicals?

Yes, there are often legal requirements for disposing of etching chemicals and other hazardous waste. These requirements vary by location, so it’s essential to check with your local authorities to ensure compliance. -

Can I sell home-etched PCBs commercially?

While it’s possible to sell home-etched PCBs commercially, it may not be practical or cost-effective due to the limited scalability and potential quality control issues associated with home etching. Most commercial applications require professionally manufactured PCBs to ensure consistent quality and reliability.

Conclusion

PCB etching at home can be a fun and educational hobby for electronics enthusiasts, but it’s crucial to consider the potential disadvantages before diving in. From health and environmental risks to time constraints and quality control issues, there are several factors to keep in mind.

If you decide to pursue PCB etching at home, be sure to prioritize safety, invest in the necessary equipment and materials, and be prepared to deal with the challenges that come with this DIY approach. By understanding the limitations and drawbacks of home etching, you can make an informed decision about whether this activity is right for you.

No responses yet