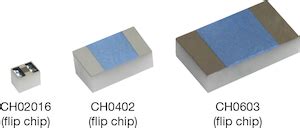

Introduction to Flip Chip Resistors

Flip chip resistors are a type of surface mount device (SMD) that have gained popularity in recent years due to their superior performance and reliability compared to traditional wire-bonded resistors. These resistors are designed with the active side facing down, allowing for direct electrical connection to the substrate or circuit board. This unique configuration offers several advantages, including improved thermal management, reduced Parasitic inductance, and better high-frequency performance.

Advantages of Flip Chip Resistors

- Enhanced thermal dissipation

- Lower parasitic inductance

- Improved high-frequency performance

- Increased power handling capability

- Better mechanical stability

Flip Chip Resistor Construction

Flip chip resistors are manufactured using advanced techniques that involve depositing a resistive material onto a ceramic substrate. The resistive material is typically a thin film of nickel-chromium (NiCr) or tantalum nitride (TaN), which is sputtered or evaporated onto the substrate. The substrate is then patterned using photolithography and etching processes to create the desired resistor geometry.

Key Components of Flip Chip Resistors

- Ceramic substrate

- Resistive material (NiCr or TaN)

- Solderable terminations

- Protective coating

Improved Performance Characteristics

Recent advancements in flip chip resistor technology have led to significant improvements in their performance characteristics. These enhancements have been achieved through optimization of the resistive material composition, substrate design, and manufacturing processes.

Improved Temperature Coefficient of Resistance (TCR)

One of the key performance metrics for resistors is their temperature coefficient of resistance (TCR), which measures the change in resistance value with respect to temperature. Flip chip resistors with improved TCR exhibit more stable resistance values across a wide temperature range, typically ±25 ppm/°C or better. This stability is crucial for applications that require precise and consistent resistance values, such as in precision analog circuits and sensors.

Enhanced Power Handling Capability

Flip chip resistors have also demonstrated improved power handling capability compared to traditional wire-bonded resistors. The direct connection between the resistive element and the substrate allows for better heat dissipation, enabling these resistors to handle higher power levels without compromising their stability or reliability. This makes flip chip resistors ideal for power-intensive applications, such as power amplifiers, Voltage Regulators, and automotive electronics.

Lower Noise Performance

Another area where flip chip resistors excel is in their noise performance. The reduced parasitic inductance and capacitance of these resistors contribute to lower noise levels, particularly at high frequencies. This is especially important in high-speed digital circuits, RF applications, and low-noise amplifiers, where Signal integrity and noise reduction are critical.

Applications of Flip Chip Resistors

Flip chip resistors find use in a wide range of applications across various industries, including:

- Telecommunications

- Automotive electronics

- Aerospace and defense

- Medical devices

- Industrial automation

Telecommunications

In the telecommunications industry, flip chip resistors are used in RF circuits, such as power amplifiers, low-noise amplifiers, and mixers. Their low parasitic inductance and excellent high-frequency performance make them well-suited for these applications, enabling higher bandwidth and improved signal quality.

Automotive Electronics

Flip chip resistors are increasingly being adopted in automotive electronics due to their reliability and stability under harsh environmental conditions. They are used in various automotive systems, such as engine control units, power management modules, and sensor interfaces. The improved power handling capability and temperature stability of flip chip resistors make them ideal for these demanding applications.

Aerospace and Defense

In the aerospace and defense sector, flip chip resistors are employed in high-reliability systems, such as avionics, radar, and satellite communications. Their robust construction and enhanced performance characteristics ensure reliable operation in extreme conditions, including high altitudes, vibration, and temperature fluctuations.

Medical Devices

Flip chip resistors are also finding applications in medical devices, particularly in implantable electronics and diagnostic equipment. Their small size, high precision, and low noise performance make them suitable for sensitive medical applications, such as pacemakers, defibrillators, and biosensors.

Industrial Automation

In industrial automation, flip chip resistors are used in a variety of applications, including process control, instrumentation, and robotics. Their improved stability and reliability contribute to the overall performance and longevity of industrial systems, reducing downtime and maintenance costs.

Future Trends in Flip Chip Resistor Technology

As the demand for high-performance electronic components continues to grow, flip chip resistor technology is expected to evolve further. Some of the future trends in this field include:

-

Miniaturization: The development of smaller flip chip resistors with higher power density will enable more compact and efficient electronic designs.

-

Advanced materials: Research into new resistive materials and substrates with improved electrical and thermal properties will enhance the performance and reliability of flip chip resistors.

-

Integration with other components: The integration of flip chip resistors with other passive components, such as capacitors and inductors, will lead to the development of multi-functional modules with reduced footprint and improved functionality.

-

Customization: The ability to tailor the properties of flip chip resistors to specific application requirements will become increasingly important, driving the development of customized solutions.

Conclusion

Flip chip resistors have emerged as a superior alternative to traditional wire-bonded resistors, offering improved performance, reliability, and power handling capability. With their unique construction and advanced manufacturing techniques, these resistors have found widespread use in various industries, including telecommunications, automotive electronics, aerospace and defense, medical devices, and industrial automation.

As technology continues to advance, flip chip resistors are expected to play an increasingly important role in enabling the development of high-performance electronic systems. Through ongoing research and innovation, the performance and capabilities of these resistors will continue to improve, driving the growth of the electronics industry and shaping the future of electronic design.

Frequently Asked Questions (FAQ)

- What are the main advantages of flip chip resistors over traditional wire-bonded resistors?

-

Flip chip resistors offer several advantages, including improved thermal dissipation, lower parasitic inductance, better high-frequency performance, increased power handling capability, and enhanced mechanical stability.

-

What materials are commonly used for the resistive element in flip chip resistors?

-

The resistive materials used in flip chip resistors are typically thin films of nickel-chromium (NiCr) or tantalum nitride (TaN), which are deposited onto a ceramic substrate using sputtering or evaporation techniques.

-

How do flip chip resistors achieve improved temperature stability?

-

Flip chip resistors achieve improved temperature stability through optimization of the resistive material composition and substrate design. This results in a lower temperature coefficient of resistance (TCR), typically ±25 ppm/°C or better, ensuring stable resistance values across a wide temperature range.

-

In which industries are flip chip resistors commonly used?

-

Flip chip resistors find applications in various industries, including telecommunications, automotive electronics, aerospace and defense, medical devices, and industrial automation. They are particularly well-suited for applications that require high performance, reliability, and stability under demanding conditions.

-

What are some of the future trends expected in flip chip resistor technology?

- Future trends in flip chip resistor technology include miniaturization, the development of advanced resistive materials and substrates, integration with other passive components, and increased customization to meet specific application requirements. These advancements will drive the continued growth and adoption of flip chip resistors in the electronics industry.

| Characteristic | Flip Chip Resistors | Wire-Bonded Resistors |

|---|---|---|

| Thermal Dissipation | Improved | Moderate |

| Parasitic Inductance | Lower | Higher |

| High-Frequency Performance | Better | Moderate |

| Power Handling Capability | Increased | Moderate |

| Mechanical Stability | Better | Moderate |

| Temperature Coefficient of Resistance (TCR) | ±25 ppm/°C or better | Higher |

| Noise Performance | Lower | Higher |

| Size | Smaller | Larger |

No responses yet