Introduction to PCB Fundamentals

Printed Circuit Boards (PCBs) are the foundation of modern electronics. Understanding the fundamentals of PCB Prototyping and design flow is crucial for anyone involved in electronic product development. This article will cover 9 key aspects of PCB fundamentals to help you navigate the PCB design process.

Understanding the PCB Design Flow

The PCB design flow consists of several stages that take an idea from concept to a functional, manufactured board. Here is a brief overview of the typical PCB design flow:

| Stage | Description |

|---|---|

| 1. Schematic Design | Create a schematic diagram of the circuit |

| 2. Component Selection | Choose appropriate components for the design |

| 3. PCB Layout | Design the physical layout of the PCB |

| 4. Design Rule Check (DRC) | Verify the layout meets manufacturing constraints |

| 5. Gerber File Generation | Generate files for PCB fabrication |

| 6. Bill of Materials (BOM) | List all components required for assembly |

| 7. PCB Fabrication | Manufacture the physical PCB |

| 8. PCB Assembly | Assemble components onto the PCB |

| 9. Testing and Debugging | Test and debug the assembled PCB |

Understanding each stage of the design flow is essential for creating a successful PCB Prototype.

Schematic Design Fundamentals

The schematic design is the first step in the PCB design process. It involves creating a diagram that represents the electrical connections between components. Some key considerations for schematic design include:

- Use clear and consistent naming conventions for components and nets

- Group related components and functions together

- Use appropriate symbols for components

- Verify the schematic against the design requirements

Component Selection Fundamentals

Selecting the right components is critical for the success of your PCB design. Some factors to consider when choosing components include:

- Functionality: Ensure the component meets the required specifications

- Footprint: Choose components with footprints that are compatible with your PCB layout

- Availability: Consider lead times and minimum order quantities

- Cost: Select components that fit within your budget constraints

PCB Layout Fundamentals

The PCB layout is the physical design of the circuit board. It involves arranging components and routing traces to create the desired electrical connections. Some key considerations for PCB layout include:

- Component placement: Arrange components for optimal signal integrity and manufacturability

- Trace routing: Route traces to minimize signal interference and maintain appropriate clearances

- Power and ground planes: Use solid planes for power and ground to reduce noise and improve signal integrity

- Design for manufacturing: Consider manufacturing constraints such as minimum trace width and spacing

Design Rule Check (DRC) Fundamentals

A Design Rule Check (DRC) is an automated check that verifies your PCB layout meets the manufacturing constraints specified by your PCB fabricator. Some common DRC checks include:

- Minimum trace width and spacing

- Minimum drill size and spacing

- Copper-to-edge clearance

- Solder mask and silkscreen rules

Running a DRC helps identify potential issues before sending your design for fabrication.

Gerber File Generation Fundamentals

Gerber files are the industry standard for communicating PCB designs to fabrication houses. They contain all the information needed to manufacture the PCB, including:

- Copper layers

- Solder mask

- Silkscreen

- Drill files

Ensuring your Gerber files are accurate and complete is essential for a smooth fabrication process.

Bill of Materials (BOM) Fundamentals

A Bill of Materials (BOM) is a comprehensive list of all the components required to assemble your PCB. It typically includes:

- Component reference designators

- Manufacturer part numbers

- Quantities

- Descriptions

An accurate BOM is critical for procurement and assembly.

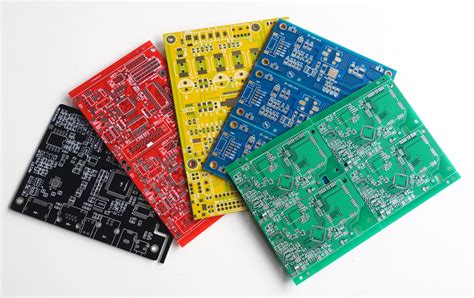

PCB Fabrication Fundamentals

PCB fabrication is the process of manufacturing the physical circuit board. Some key aspects of PCB fabrication include:

- Material selection (e.g., FR-4, Rogers, etc.)

- Copper weight and thickness

- Surface finish (e.g., HASL, ENIG, OSP)

- Controlled impedance requirements

Understanding the fabrication process can help you make informed design decisions and communicate effectively with your fabrication partner.

PCB Assembly Fundamentals

PCB assembly involves soldering components onto the fabricated circuit board. There are two main types of assembly:

-

Through-hole assembly: Components with leads are inserted into holes drilled in the PCB and soldered in place.

-

Surface-mount assembly: Components are placed on pads on the surface of the PCB and soldered using reflow or wave soldering techniques.

Designing your PCB with assembly in mind can help reduce costs and improve manufacturability.

Testing and Debugging Fundamentals

After assembly, your PCB prototype needs to be tested and debugged to ensure it functions as intended. Some common testing and debugging techniques include:

- Visual inspection

- Continuity testing

- Power-on testing

- Functional testing

- In-circuit testing

- Boundary scan testing

Having a comprehensive testing plan can help identify and resolve issues quickly.

PCB Prototyping Best Practices

To ensure a successful PCB prototyping process, consider the following best practices:

- Start with a clear and complete set of design requirements

- Use a version control system to track changes to your design files

- Collaborate closely with your PCB fabrication and assembly partners

- Perform thorough design reviews and DRCs before sending files for fabrication

- Plan for testing and debugging early in the design process

- Document your design thoroughly, including schematics, BOMs, and test plans

- Consider design for manufacturability (DFM) and design for assembly (DFA) principles

- Prototype early and often to catch issues and iterate on your design

- Learn from each prototype iteration and incorporate feedback into future designs

By following these best practices, you can streamline your PCB prototyping process and increase your chances of success.

FAQ

- What is the difference between a schematic and a PCB layout?

-

A schematic is a diagram that represents the electrical connections between components, while a PCB layout is the physical design of the circuit board, showing component placement and trace routing.

-

What is a Design Rule Check (DRC)?

-

A DRC is an automated check that verifies your PCB layout meets the manufacturing constraints specified by your PCB fabricator, such as minimum trace width and spacing, drill sizes, and clearances.

-

What are Gerber files, and why are they important?

-

Gerber files are the industry standard for communicating PCB designs to fabrication houses. They contain all the information needed to manufacture the PCB, including copper layers, solder mask, silkscreen, and drill files.

-

What is a Bill of Materials (BOM), and why is it important?

-

A BOM is a comprehensive list of all the components required to assemble your PCB, including reference designators, part numbers, quantities, and descriptions. An accurate BOM is critical for procurement and assembly.

-

What are some common PCB testing and debugging techniques?

- Common PCB testing and debugging techniques include visual inspection, continuity testing, power-on testing, functional testing, in-circuit testing, and boundary scan testing. A comprehensive testing plan can help identify and resolve issues quickly.

Conclusion

Understanding the fundamentals of PCB prototyping and design flow is essential for anyone involved in electronic product development. By following best practices and considering key aspects such as schematic design, component selection, PCB layout, DRC, Gerber files, BOM, fabrication, assembly, and testing, you can create successful PCB prototypes and bring your ideas to life.

No responses yet