What is a PCB Relay?

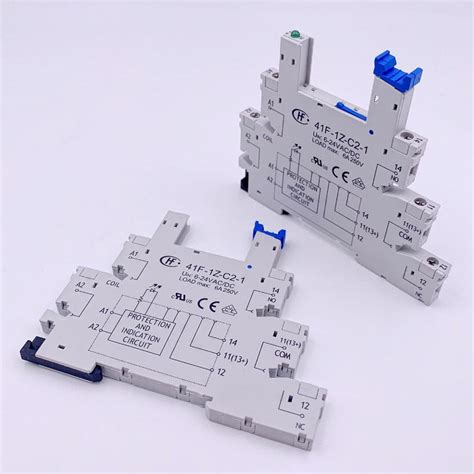

A PCB relay is a small, electromechanical device that is designed to be mounted directly onto a printed circuit board. It consists of an electromagnet, a set of contacts, and a switching mechanism encased in a compact package. The primary function of a PCB relay is to switch electrical circuits on or off based on an input signal.

PCB relays offer several advantages over traditional relays:

- Compact size: PCB relays are significantly smaller than their traditional counterparts, making them ideal for space-constrained applications.

- Easy integration: As PCB relays are designed to be mounted directly onto PCBs, they can be easily integrated into electronic circuits during the manufacturing process.

- High reliability: PCB relays are known for their high reliability and long operational life, thanks to their robust construction and sealed design.

- Low power consumption: Many PCB relays are designed to operate on low power, making them suitable for battery-powered devices and energy-efficient systems.

How Does a PCB Relay Work?

The working principle of a PCB relay is based on the interaction between an electromagnet and a set of contacts. When an electric current is applied to the electromagnet’s coil, it generates a magnetic field that attracts an armature. The armature, in turn, moves a set of contacts, either closing or opening the electrical circuit connected to the relay.

Here’s a step-by-step breakdown of the PCB relay’s operation:

- In the default state, the relay’s contacts are either normally open (NO) or normally closed (NC), depending on the relay’s design.

- When an input signal is applied to the relay’s coil, an electric current flows through the coil, creating a magnetic field.

- The magnetic field attracts the armature, which is typically made of a ferromagnetic material.

- As the armature moves, it either closes the NO contacts or opens the NC contacts, depending on the relay’s configuration.

- When the input signal is removed, the magnetic field dissipates, and the armature returns to its original position, either opening the NO contacts or closing the NC contacts.

The following table summarizes the two main types of PCB relay contacts:

| Contact Type | Default State | Energized State |

|---|---|---|

| Normally Open (NO) | Open | Closed |

| Normally Closed (NC) | Closed | Open |

Types of PCB Relays

PCB relays come in various types, each designed to cater to specific applications and requirements. Some of the most common types of PCB relays include:

1. Electromechanical Relays (EMRs)

Electromechanical relays are the most basic type of PCB relays. They consist of an electromagnet, an armature, and a set of contacts. EMRs offer high isolation between the input and output circuits, making them suitable for applications that require electrical isolation.

2. Solid State Relays (SSRs)

Solid state relays use semiconductor devices, such as thyristors or triacs, to switch electrical circuits. Unlike EMRs, SSRs have no moving parts, making them more durable and faster in operation. However, they provide less electrical isolation compared to EMRs.

3. Reed Relays

Reed relays consist of a pair of ferromagnetic reed switches sealed in a glass envelope. When a magnetic field is applied, the reed switches attract each other, closing the electrical circuit. Reed relays are known for their fast switching speeds and low power consumption.

4. Latching Relays

Latching relays, also known as bistable relays, maintain their state even after the input signal is removed. They require a pulse to switch between states, making them suitable for applications that require low power consumption and state retention during power failures.

Applications of PCB Relays

PCB relays find applications in a wide range of industries and devices. Some common applications include:

- Automotive electronics: PCB relays are used in various automotive systems, such as lighting control, power windows, and engine management.

- Industrial automation: PCB relays are employed in industrial control systems, such as programmable logic controllers (PLCs) and distributed control systems (DCS).

- Telecommunications: PCB relays are used in telephone exchanges, modems, and other communication devices for signal routing and switching.

- Medical equipment: PCB relays are found in medical devices, such as patient monitoring systems and diagnostic equipment, where reliability and isolation are critical.

- Consumer electronics: PCB relays are used in home appliances, audio/video equipment, and other consumer devices for power management and switching functions.

The following table summarizes the key applications of PCB relays across different industries:

| Industry | Applications |

|---|---|

| Automotive | Lighting control, power windows, engine management |

| Industrial Automation | PLCs, DCS, process control |

| Telecommunications | Telephone exchanges, modems, signal routing |

| Medical Equipment | Patient monitoring, diagnostic devices |

| Consumer Electronics | Home appliances, audio/video equipment, power management |

Selecting the Right PCB Relay

When choosing a PCB relay for a specific application, several factors need to be considered:

- Voltage and current ratings: Ensure that the relay’s voltage and current ratings are compatible with the application’s requirements.

- Contact arrangement: Choose between NO, NC, or changeover contacts based on the switching requirements of the circuit.

- Coil voltage and power consumption: Select a relay with a coil voltage that matches the available input signal and consider the power consumption of the relay.

- Switching speed: Consider the required switching speed of the application and choose a relay that meets those requirements.

- Environmental factors: Take into account the operating temperature, humidity, and other environmental factors that may affect the relay’s performance.

Frequently Asked Questions (FAQ)

1. What is the difference between a PCB relay and a regular relay?

A PCB relay is designed to be mounted directly onto a printed circuit board, whereas a regular relay is a standalone component that is wired into a circuit. PCB relays are generally smaller and more compact than regular relays.

2. Can PCB relays handle high voltage and current?

Yes, there are PCB relays available that are designed to handle high voltage and current applications. However, it is essential to select a relay with the appropriate ratings for the specific application.

3. Are PCB relays more expensive than regular relays?

The cost of PCB relays varies depending on the type, ratings, and features. While some PCB relays may be more expensive than regular relays, their compact size and ease of integration can lead to overall cost savings in the manufacturing process.

4. How long do PCB relays typically last?

The lifespan of a PCB relay depends on factors such as the type of relay, its usage, and the environmental conditions. Generally, PCB relays are designed to offer a long operational life, with many rated for millions of switching cycles.

5. Can PCB relays be replaced if they fail?

In most cases, PCB relays are designed to be replaced rather than repaired. However, the ease of replacement depends on the specific design of the PCB and the accessibility of the relay.

Conclusion

PCB relays are essential components in modern electronic systems, offering reliable switching and power management capabilities in a compact package. By understanding the working principle, types, and applications of PCB relays, engineers and technicians can select the most suitable relay for their specific needs.

As technology continues to advance, PCB relays are expected to evolve, offering even smaller sizes, higher performance, and more advanced features. With their widespread use across various industries, PCB relays will continue to play a crucial role in shaping the future of electronics.

No responses yet