Table of Contents

- Daisy-Chain-Routing“>What is Daisy Chain Routing?

- Advantages of Daisy Chain Routing

- Disadvantages of Daisy Chain Routing

- Applications of Daisy Chain Routing

- Computer Networking

- Audio/Video Systems

- Lighting Control

- Industrial Automation

- Implementing Daisy Chain Routing

- Planning and Design

- Hardware Requirements

- Configuration and Setup

- Best Practices for Daisy Chain Routing

- Troubleshooting Daisy Chain Routing

- Frequently Asked Questions (FAQ)

- Conclusion

What is Daisy Chain Routing?

Daisy chain routing is a method of connecting multiple devices together in a series, where the output of one device is connected to the input of the next device, forming a chain-like structure. This allows data or signals to flow sequentially through each device in the chain.

In a daisy chain configuration, each device has an input and an output port. The output port of the first device is connected to the input port of the second device, the output port of the second device is connected to the input port of the third device, and so on. The last device in the chain may have its output port connected back to the input port of the first device, forming a complete loop, or it may terminate the chain.

Advantages of Daisy Chain Routing

Daisy chain routing offers several advantages over other connection methods:

- Simplicity: Daisy chaining is a straightforward and easy-to-understand approach to connecting multiple devices. It requires minimal cabling and configuration, making it simpler to set up and maintain compared to other more complex topologies.

- Cost-effectiveness: By using a daisy chain configuration, you can reduce the number of cables and connectors needed, as each device only requires one input and one output connection. This can lead to cost savings, especially in large-scale installations.

- Scalability: Daisy chain routing allows you to easily add or remove devices from the chain without disrupting the entire system. You can simply connect a new device to the end of the chain or disconnect a device from the chain without affecting the other devices.

- Flexibility: Daisy chaining can be used with various types of devices and protocols, making it adaptable to different applications and environments. It is commonly used with devices that support daisy chain functionality, such as Ethernet switches, DMX lighting controllers, and audio/video equipment.

Disadvantages of Daisy Chain Routing

While daisy chain routing has its benefits, it also has some limitations and drawbacks:

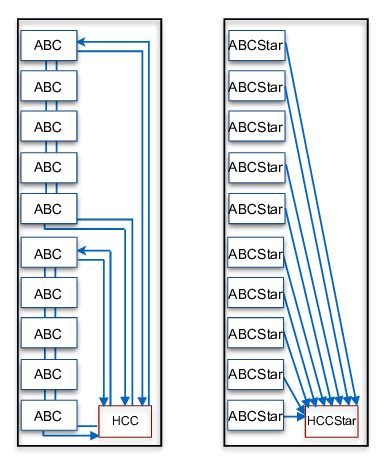

- Single point of failure: In a daisy chain configuration, if one device in the chain fails or loses power, it can disrupt the communication for all the devices downstream. This is because the data or signal flow relies on each device passing it along to the next. A failure in any device can break the chain and affect the entire system.

- Limited bandwidth: As data or signals pass through each device in the chain, there is a potential for bandwidth degradation. Each device introduces some latency and may have limitations on the amount of data it can process or transmit. This can result in reduced performance, especially in long chains or when dealing with high-bandwidth applications.

- Increased latency: Daisy chain routing introduces additional latency as data or signals have to travel through each device in the chain. The more devices in the chain, the higher the latency. This can be a concern for time-sensitive applications or real-time systems that require low latency.

- Troubleshooting complexity: When issues arise in a daisy chain configuration, troubleshooting can be more challenging. Identifying the source of the problem may require checking each device in the chain individually, which can be time-consuming. Isolating and resolving issues in a daisy chain setup can be more complex compared to other topologies.

Applications of Daisy Chain Routing

Daisy chain routing finds application in various domains, including computer networking, audio/video systems, lighting control, and industrial automation. Let’s explore each of these areas in more detail.

Computer Networking

In computer networking, daisy chain routing is commonly used with Ethernet switches. Ethernet switches can be connected in a daisy chain configuration to expand the network and provide connectivity to multiple devices. This is particularly useful in scenarios where there are limited Ethernet ports available or when extending the network to different locations.

Here’s an example of how Ethernet switches can be connected in a daisy chain:

| Switch 1 | Switch 2 | Switch 3 |

|---|---|---|

| Port 1 (Input) | Port 1 (Input from Switch 1) | Port 1 (Input from Switch 2) |

| Port 2 (Output to Switch 2) | Port 2 (Output to Switch 3) | Port 2 (Output) |

| Port 3 (Device 1) | Port 3 (Device 2) | Port 3 (Device 3) |

| Port 4 (Device 4) | Port 4 (Device 5) | Port 4 (Device 6) |

In this example, three Ethernet switches are connected in a daisy chain. Switch 1’s output port is connected to Switch 2’s input port, and Switch 2’s output port is connected to Switch 3’s input port. Each switch also has devices connected to its remaining ports.

Audio/Video Systems

Daisy chain routing is widely used in professional audio and video systems. Audio devices, such as mixers, amplifiers, and speakers, can be connected in a daisy chain to distribute audio signals. Similarly, video devices, like cameras, monitors, and projectors, can be daisy-chained to route video signals.

Here’s an example of how audio devices can be connected in a daisy chain:

| Mixer | Amplifier 1 | Amplifier 2 |

|---|---|---|

| Output 1 (to Amplifier 1) | Input (from Mixer) | Input (from Amplifier 1) |

| Output 2 (to Amplifier 2) | Output (to Speakers 1 & 2) | Output (to Speakers 3 & 4) |

In this setup, the mixer’s outputs are connected to the inputs of the amplifiers in a daisy chain. Amplifier 1 receives the signal from the mixer and passes it along to Amplifier 2. Each amplifier then drives its respective speakers.

Lighting Control

Daisy chain routing is commonly used in lighting control systems, particularly those using the DMX (Digital Multiplex) protocol. DMX is a standard for controlling stage lighting and effects. Lighting fixtures, such as dimmer packs, LED lights, and moving heads, can be daisy-chained together using DMX cables.

Here’s an example of how lighting fixtures can be connected in a daisy chain:

| DMX Controller | Dimmer Pack 1 | Dimmer Pack 2 |

|---|---|---|

| DMX Output (to Dimmer Pack 1) | DMX Input (from Controller) | DMX Input (from Dimmer Pack 1) |

| DMX Output (to Dimmer Pack 2) | DMX Output (to LED Lights) | |

| Dimmer Outputs (to Lights 1-4) | Dimmer Outputs (to Lights 5-8) |

In this configuration, the DMX controller sends control signals to Dimmer Pack 1, which then passes the signal to Dimmer Pack 2. Each dimmer pack controls its respective lights based on the received DMX signals.

Industrial Automation

Daisy chain routing is used in industrial automation systems to connect various devices, such as programmable logic controllers (PLCs), sensors, and actuators. It allows for efficient communication and control in manufacturing processes and automated systems.

Here’s an example of how devices can be connected in a daisy chain in an industrial automation setup:

| PLC | Sensor 1 | Sensor 2 | Actuator |

|---|---|---|---|

| Output (to Sensor 1) | Input (from PLC) | Input (from Sensor 1) | Input (from Sensor 2) |

| Output (to Sensor 2) | Output (to Actuator) | Output (to PLC) |

In this scenario, the PLC sends control signals to Sensor 1, which passes the signal to Sensor 2. Sensor 2 then sends the signal to the Actuator, which performs a specific action based on the received command. The Actuator’s output is connected back to the PLC, completing the daisy chain loop.

Implementing Daisy Chain Routing

To successfully implement daisy chain routing in your system, you need to consider several factors, including planning and design, hardware requirements, and configuration and setup.

Planning and Design

Before implementing daisy chain routing, it’s crucial to plan and design your system carefully. Consider the following aspects:

- Number of devices: Determine the total number of devices you need to connect in the daisy chain. This will help you assess the feasibility and scalability of the daisy chain configuration.

- Device compatibility: Ensure that all the devices you intend to use in the daisy chain are compatible with each other and support the required protocols or standards. Check the manufacturer’s specifications and guidelines for daisy chain compatibility.

- Cable length and type: Consider the total length of the daisy chain and the maximum cable length supported by each device. Choose appropriate cable types that meet the requirements of your devices and maintain signal integrity over the desired distances.

- Bandwidth requirements: Assess the bandwidth requirements of your applications and ensure that the daisy chain configuration can support the necessary data rates. Consider the potential for bandwidth degradation as the signal passes through multiple devices.

- Power management: Determine how power will be distributed to the devices in the daisy chain. Some devices may have built-in power supply units, while others may require external power sources. Plan for adequate power distribution and consider the power consumption of each device.

Hardware Requirements

To implement daisy chain routing, you need to have the necessary hardware components:

- Devices with daisy chain support: Ensure that the devices you are using have the required input and output ports for daisy chaining. Look for devices that specifically mention daisy chain functionality in their specifications.

- Cables and connectors: Use appropriate cables and connectors that are compatible with your devices and meet the required specifications. Common cable types used for daisy chaining include Ethernet cables, DMX cables, and XLR cables, depending on the application.

- Terminators: In some cases, you may need to use terminators at the end of the daisy chain to ensure proper signal termination and prevent reflections. Terminators are typically resistors or specialized plugs that match the characteristic impedance of the cable.

Configuration and Setup

Once you have the necessary hardware, you can proceed with configuring and setting up your daisy chain system:

- Connect the devices: Start by connecting the output port of the first device to the input port of the second device, and continue the chain by connecting the output of each subsequent device to the input of the next one. Ensure that the cables are securely connected and properly seated.

- Configure device settings: Access the configuration settings of each device in the daisy chain. Set the appropriate parameters, such as device ID, communication protocol, and any other relevant settings. Refer to the device’s user manual for specific configuration instructions.

- Terminate the chain: If required, add a terminator to the last device in the chain to prevent signal reflections and ensure proper termination. Consult the device’s documentation to determine if termination is necessary and how to properly terminate the chain.

- Test and verify: Once the daisy chain is set up, perform thorough testing to ensure that communication is functioning correctly. Send test signals or commands through the chain and verify that each device responds as expected. Check for any signal degradation or unexpected behavior.

- Document the setup: Create a detailed documentation of your daisy chain setup, including the device connections, cable lengths, and configuration settings. This documentation will be valuable for future reference, troubleshooting, and maintenance purposes.

Best Practices for Daisy Chain Routing

To optimize the performance and reliability of your daisy chain system, consider the following best practices:

- Keep the chain short: Whenever possible, try to minimize the number of devices in the daisy chain. Longer chains are more susceptible to signal degradation and increased latency. If you have a large number of devices, consider using multiple shorter daisy chains or alternative topologies.

- Use high-quality cables: Invest in high-quality, well-shielded cables that are designed for daisy chaining applications. Poor-quality cables can introduce signal interference, crosstalk, and reliability issues. Ensure that the cables meet the required specifications for your devices and application.

- Maintain proper cable management: Keep the daisy chain cables neat and organized to avoid tangles, kinks, or excessive bending. Use cable ties, labeling, and proper cable routing techniques to ensure a clean and manageable installation. Proper cable management helps prevent physical damage to the cables and improves overall system reliability.

- Avoid exceeding cable length limits: Be mindful of the maximum cable length supported by your devices and the daisy chain protocol. Exceeding the recommended cable lengths can lead to signal degradation, data loss, or communication failures. Consult the device specifications and guidelines for maximum cable lengths.

- Use appropriate termination: If your daisy chain system requires termination, ensure that you use the correct terminator values and properly terminate the last device in the chain. Improper termination can cause signal reflections, noise, and communication issues.

- Monitor and maintain the system: Regularly monitor the performance and health of your daisy chain system. Keep an eye out for any signs of signal degradation, communication errors, or device failures. Perform routine maintenance, such as cleaning connectors, checking cable integrity, and updating device firmware if necessary.

- Plan for redundancy: In critical applications where system uptime is crucial, consider implementing redundancy measures. This can include using redundant power supplies, backup devices, or alternative communication paths. Redundancy helps mitigate the impact of single points of failure in the daisy chain.

Troubleshooting Daisy Chain Routing

Despite best efforts, issues can still arise in daisy chain systems. Here are some common troubleshooting steps to help identify and resolve problems:

- Check cable connections: Ensure that all cables are securely connected and properly seated. Loose or damaged connectors can cause intermittent communication issues or complete failures. Inspect the cables for any signs of physical damage, such as frayed wires or bent pins.

- Verify device configurations: Double-check the configuration settings of each device in the daisy chain. Ensure that the device IDs, communication protocols, and other relevant settings are correctly configured and consistent across the chain. Incorrect configurations can lead to communication failures or unexpected behavior.

- Isolate the problem: If you suspect a device or cable issue, try isolating the problem by temporarily removing devices from the chain or swapping cables. This can help identify the specific component causing the issue. Start by isolating devices or cable segments one at a time and observe if the problem persists.

- Check termination: If your daisy chain system requires termination, verify that the terminator is properly connected and has the correct value. Improper termination can cause signal reflections and communication errors. Consult the device documentation for termination requirements and guidelines.

- Monitor device status: Many devices in a daisy chain system have status indicators, such as LEDs, that provide information about the device’s health and communication status. Check these indicators for any error codes or abnormal behavior. Refer to the device’s user manual for information on interpreting status indicators.

- Update firmware: Ensure that all devices in the daisy chain are running the latest firmware versions. Firmware updates often include bug fixes, performance improvements, and compatibility enhancements. Check the manufacturer’s website for firmware updates and follow the provided instructions for upgrading the devices.

- Seek technical support: If you are unable to resolve the issue on your own, don’t hesitate to reach out to the device manufacturer’s technical support team. They can provide guidance, troubleshooting steps, and assistance specific to your devices and application.

No responses yet