Introduction to Circuit Boards

Circuit boards, also known as printed circuit boards (PCBs), are essential components in modern electronics. They provide a platform for electrical components to be mounted and interconnected, forming a complete electrical circuit. Circuit boards come in various types, each with its own unique characteristics and applications. In this article, we will explore the different types of circuit boards and their uses.

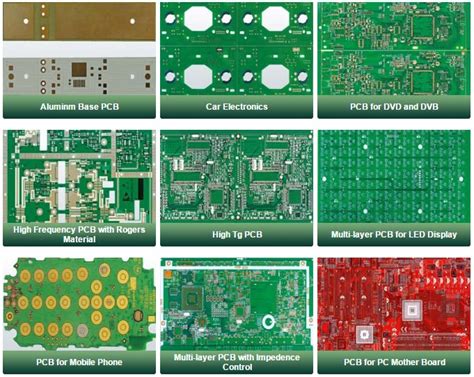

Types of Circuit Boards

1. Single Layer PCB

Single layer PCBs consist of a single conductive layer, usually made of copper, laminated onto an insulating substrate. The copper layer is etched to form the desired circuit pattern. Single layer PCBs are the simplest and most cost-effective type of circuit board. They are commonly used in simple electronic devices such as calculators, toys, and low-power applications.

2. Double Layer PCB

Double layer PCBs have two conductive layers, one on each side of the insulating substrate. The layers are connected through plated holes called vias. Double layer PCBs offer more design flexibility and higher component density compared to single layer PCBs. They are widely used in consumer electronics, telecommunications equipment, and industrial control systems.

3. Multi-Layer PCB

Multi-layer PCBs consist of three or more conductive layers laminated together with insulating material in between. The layers are interconnected using vias. Multi-layer PCBs allow for complex circuit designs and high component density. They are used in advanced electronic devices such as smartphones, computers, medical equipment, and aerospace systems.

| Layer Count | Typical Applications |

|---|---|

| 4-6 layers | High-speed digital circuits, RF circuits |

| 8-10 layers | Complex digital systems, high-density interconnects |

| 12+ layers | Advanced computing systems, military and aerospace applications |

4. Flexible PCB

Flexible PCBs, also known as flex circuits, are made using a flexible insulating material such as polyimide or polyester. They can be bent, twisted, and folded to fit into tight spaces or conform to curved surfaces. Flexible PCBs are commonly used in wearable electronics, medical devices, and aerospace applications where traditional rigid PCBs are not suitable.

5. Rigid-Flex PCB

Rigid-flex PCBs combine the benefits of both rigid and flexible PCBs. They consist of rigid PCB sections connected by flexible PCB sections. Rigid-flex PCBs offer the advantage of reducing the number of connectors and improving reliability. They are used in applications that require a combination of stability and flexibility, such as automotive electronics, robotics, and portable devices.

6. High Frequency PCB

High frequency PCBs are designed to handle high-speed signals and minimize signal integrity issues. They use special materials with controlled dielectric constants and low loss tangents to minimize signal distortion and attenuation. High frequency PCBs are used in applications such as radar systems, wireless communications, and high-speed digital circuits.

7. Aluminum PCB

Aluminum PCBs have an aluminum substrate instead of the traditional FR-4 material. The aluminum substrate provides excellent heat dissipation properties, making them suitable for high-power applications. Aluminum PCBs are commonly used in LED lighting, power electronics, and automotive applications where heat management is critical.

PCB Manufacturing Process

The manufacturing process of PCBs involves several steps:

1. Design: The circuit design is created using PCB design software, which generates the necessary files for manufacturing.

2. Fabrication: The PCB is fabricated by laminating the conductive layers, drilling holes, and applying a protective coating.

3. Assembly: Electronic components are mounted onto the PCB using various techniques such as through-hole or surface mount technology (SMT).

4. Testing: The assembled PCB undergoes rigorous testing to ensure functionality and reliability.

Advantages of Using Circuit Boards

Circuit boards offer several advantages over traditional point-to-point wiring:

– Compact size and weight reduction

– Improved reliability and consistency

– Increased production efficiency and automation

– Better signal integrity and reduced electromagnetic interference (EMI)

– Easier troubleshooting and maintenance

Frequently Asked Questions (FAQ)

1. What is the difference between a single layer and double layer PCB?

A single layer PCB has only one conductive layer, while a double layer PCB has two conductive layers, one on each side of the insulating substrate. Double layer PCBs offer more design flexibility and higher component density compared to single layer PCBs.

2. What are vias in a PCB?

Vias are plated holes that provide electrical connections between different layers of a multi-layer PCB. They allow signals to pass from one layer to another, enabling more complex circuit designs.

3. What are the advantages of using flexible PCBs?

Flexible PCBs offer several advantages, including:

– Ability to conform to curved surfaces or fit into tight spaces

– Reduced weight and improved portability

– Increased durability and resistance to vibration and shock

– Simplified assembly and reduced connectors

4. What is the purpose of using high frequency PCBs?

High frequency PCBs are designed to handle high-speed signals and minimize signal integrity issues. They use special materials and design techniques to reduce signal distortion and attenuation, ensuring reliable performance in high-speed applications.

5. What are the steps involved in the PCB manufacturing process?

The PCB manufacturing process typically involves four main steps: design, fabrication, assembly, and testing. The design phase involves creating the circuit layout using PCB design software. Fabrication involves laminating the conductive layers, drilling holes, and applying a protective coating. Assembly involves mounting electronic components onto the PCB, and testing ensures the functionality and reliability of the assembled PCB.

Conclusion

Circuit boards are fundamental components in modern electronics, providing a platform for interconnecting electronic components and forming complete electrical circuits. Understanding the different types of circuit boards and their applications is crucial for designing and manufacturing reliable and efficient electronic devices.

From simple single layer PCBs to complex multi-layer and flexible PCBs, each type has its own advantages and specific use cases. The choice of circuit board depends on factors such as the complexity of the circuit, the operating environment, and the desired performance characteristics.

As technology continues to advance, the demand for more sophisticated and high-performance circuit boards will continue to grow. Innovations in materials, manufacturing processes, and design tools will enable the development of even more advanced and reliable electronic devices in the future.

No responses yet