Understanding Relay Connection Basics

A relay is an electrically operated switch that allows you to control a high-current circuit with a low-current signal. It works by using an electromagnet to mechanically operate a switch, which can be used to turn on or off a large electrical current. Relays are commonly used in various applications, such as automotive systems, industrial control systems, and home automation projects.

To connect a relay efficiently, it is essential to understand the basic components and their functions:

-

Coil: The coil is the part of the relay that creates the magnetic field when energized. It consists of a wire wound around a metal core.

-

Armature: The armature is a movable piece of metal that is attracted to the coil when it is energized. It is responsible for opening and closing the switch contacts.

-

Switch Contacts: The switch contacts are the electrical connections that are opened or closed by the armature. They are typically made of silver or gold-plated silver for good conductivity and durability.

-

Spring: The spring is used to return the armature to its original position when the coil is de-energized.

Types of Relays

There are several types of relays, each with its own specific characteristics and applications:

-

Electromechanical Relays (EMRs): These are the most common type of relays, which use an electromagnet to operate the switch contacts. They are reliable, inexpensive, and can handle high current loads.

-

Solid-State Relays (SSRs): These relays use semiconductor devices, such as thyristors or transistors, to switch the load. They have no moving parts, making them more durable and faster than EMRs. However, they are more expensive and have a lower current handling capacity.

-

Reed Relays: These relays use a pair of ferromagnetic contacts sealed in a glass tube. They are activated by an external magnetic field, making them ideal for low-current, high-speed switching applications.

-

Time-Delay Relays: These relays incorporate a time-delay mechanism that allows them to delay the switching action by a predetermined amount of time. They are useful in applications where a delay is required, such as in motor starting circuits.

Choosing the Right Relay

When selecting a relay for your project, consider the following factors:

-

Voltage and Current Rating: Ensure that the relay’s coil voltage and switch contact current ratings are compatible with your application.

-

Contact Arrangement: Relays are available in various contact arrangements, such as SPST (Single Pole, Single Throw), SPDT (Single Pole, Double Throw), and DPDT (Double Pole, Double Throw). Choose the arrangement that best suits your needs.

-

Coil Resistance: The coil resistance determines the amount of current required to energize the relay. A higher resistance coil will require less current, but may be slower to operate.

-

Switching Speed: If your application requires fast switching, consider using a solid-state relay or a reed relay.

-

Environmental Factors: Consider the operating environment of your relay, such as temperature, humidity, and vibration. Some relays are designed to withstand harsh conditions, while others may require additional protection.

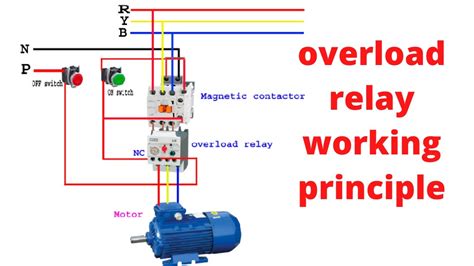

Relay Connection Diagrams

To connect a relay efficiently, it is important to follow the manufacturer’s wiring diagram. Here are some common relay connection diagrams:

SPST Relay Connection

An SPST relay has one set of switch contacts that can be either normally open (NO) or normally closed (NC). To connect an SPST relay:

- Connect the coil terminals to the control circuit, typically a low-voltage DC source.

- Connect the switch contacts in series with the load and the power source.

| Control Circuit | Switch Contacts |

|---|---|

| (+) Coil | COM |

| (-) Coil | NO or NC |

SPDT Relay Connection

An SPDT relay has one set of switch contacts that can be either NO or NC, and a common terminal. To connect an SPDT relay:

- Connect the coil terminals to the control circuit.

- Connect the common terminal to the power source.

- Connect the NO or NC terminal to the load, depending on your application.

| Control Circuit | Switch Contacts |

|---|---|

| (+) Coil | COM |

| (-) Coil | NO |

| NC |

DPDT Relay Connection

A DPDT relay has two sets of switch contacts, each with a common terminal and either NO or NC terminals. To connect a DPDT relay:

- Connect the coil terminals to the control circuit.

- Connect the common terminals to the power source.

- Connect the NO or NC terminals to the loads, depending on your application.

| Control Circuit | Switch Contacts |

|---|---|

| (+) Coil | COM1 |

| (-) Coil | NO1 |

| NC1 | |

| COM2 | |

| NO2 | |

| NC2 |

Relay Protection Circuits

To protect your relay and extend its lifespan, consider implementing the following protection circuits:

-

Flyback Diode: When the relay coil is de-energized, the collapsing magnetic field can induce a high-voltage spike across the coil terminals. A flyback diode connected in parallel with the coil can help suppress this voltage spike and protect the control circuit.

-

Snubber Circuit: In applications where the relay is switching an inductive load, such as a motor or solenoid, a snubber circuit can be used to suppress the voltage and current spikes generated by the load. A typical snubber circuit consists of a resistor and a capacitor connected in series, and then placed in parallel with the switch contacts.

-

Fuse: A fuse can be used to protect the relay and the load from overcurrent conditions. Choose a fuse with a rating slightly higher than the maximum expected load current.

Relay Application Examples

Relays are used in a wide range of applications, from simple home automation projects to complex industrial control systems. Here are a few examples:

-

Automotive Systems: Relays are used in various automotive applications, such as controlling headlights, horns, and fuel pumps.

-

Industrial Control: Relays are commonly used in industrial control systems to switch high-power loads, such as motors, solenoids, and heaters.

-

Home Automation: Relays can be used in home automation projects to control lighting, appliances, and HVAC systems.

-

Battery Charging: Relays can be used to control the charging of batteries in solar power systems and other battery-powered applications.

Frequently Asked Questions (FAQ)

-

Q: What is the difference between a relay and a contactor?

A: Relays and contactors are both electrically operated switches, but contactors are designed to handle higher current loads and are typically used in industrial applications. Relays are smaller and are used in a wider range of applications, including low-power control circuits. -

Q: Can I use a solid-state relay to switch an AC load?

A: Yes, solid-state relays are available in both AC and DC versions. Make sure to choose a relay with the appropriate voltage and current ratings for your application. -

Q: How do I choose the right coil voltage for my relay?

A: The coil voltage should match the voltage of your control circuit. Common coil voltages include 5V, 12V, 24V, and 120V AC or DC. -

Q: What is the purpose of the armature in a relay?

A: The armature is the moving part of the relay that is attracted to the coil when it is energized. It is responsible for opening and closing the switch contacts. -

Q: Can I use a relay to control a high-voltage load?

A: Yes, relays are available with switch contacts rated for high-voltage loads. However, make sure to choose a relay with the appropriate voltage and current ratings, and consider using additional protection circuits, such as fuses and snubbers.

Conclusion

Connecting a relay efficiently requires understanding the basic components, choosing the right type of relay for your application, and following the manufacturer’s wiring diagram. Implementing protection circuits, such as flyback diodes and snubbers, can help extend the life of your relay and protect your control circuit. By following these guidelines and considering the specific requirements of your project, you can successfully incorporate relays into your designs and take advantage of their versatility and reliability.

No responses yet