What is a Breadboard?

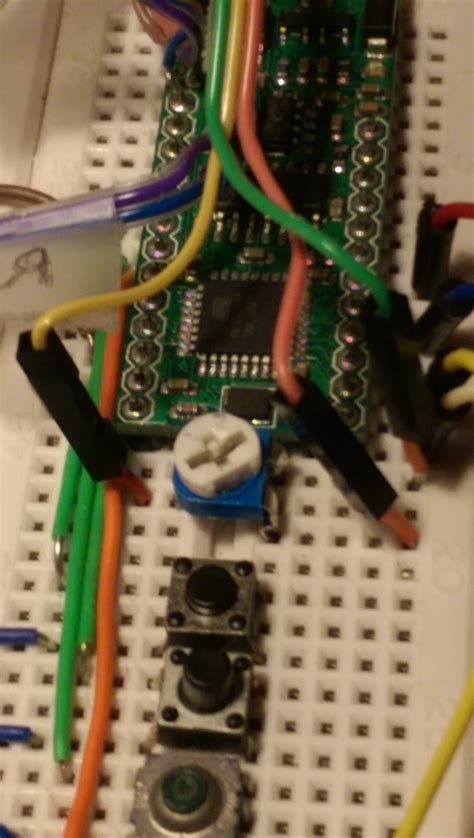

A breadboard is a reusable prototyping tool used to build and test electronic circuits without the need for soldering. It consists of a plastic board with a grid of holes, into which electronic components and jumper wires can be inserted. The holes are connected internally in a specific pattern, allowing you to create electrical connections between components.

Advantages of Breadboards

- Quick and easy prototyping

- Reusable and reconfigurable

- No soldering required

- Ideal for beginners and educational purposes

Disadvantages of Breadboards

- Limited circuit complexity

- Prone to loose connections and short circuits

- Not suitable for permanent or durable projects

- Limited current-carrying capacity

What is a PCB?

A printed circuit board (PCB) is a custom-designed board that permanently connects electronic components using conductive tracks, pads, and other features. PCBs are fabricated using a multi-step process that includes designing the circuit, creating a copper trace layout, and etching the board.

Advantages of PCBs

- Compact and space-efficient

- Durable and reliable

- Higher current-carrying capacity

- Suitable for complex circuits

- Professional appearance

Disadvantages of PCBs

- Higher initial cost

- Requires design and fabrication time

- Not easily modifiable once fabricated

- Requires soldering skills

Comparing Breadboards and PCBs

To help you decide between breadboards and PCBs, let’s compare them based on several key factors:

| Factor | Breadboard | PCB |

|---|---|---|

| Prototyping speed | Fast | Slow |

| Reusability | High | Low |

| Durability | Low | High |

| Circuit complexity | Low to Medium | High |

| Current-carrying capacity | Low | High |

| Cost | Low | High |

| Appearance | Temporary | Professional |

| Soldering required | No | Yes |

Choosing Between Breadboards and PCBs

When deciding between breadboards and PCBs, consider the following factors:

-

Project complexity: If your project involves a simple circuit with few components, a breadboard may suffice. However, for more complex projects with numerous components and connections, a PCB is the better choice.

-

Durability: If your project needs to be durable and long-lasting, a PCB is the way to go. Breadboards are more suitable for temporary prototypes and testing.

-

Cost: Breadboards are generally cheaper than PCBs, especially for small-scale projects. However, for larger production runs or complex designs, PCBs can be more cost-effective in the long run.

-

Time constraints: Breadboards allow for quick prototyping and iterations, while PCBs require design and fabrication time. If you need to quickly test and modify your circuit, a breadboard is the better option.

-

Skill level: Breadboards are beginner-friendly and require no soldering, making them ideal for those new to electronics. PCBs, on the other hand, require soldering skills and a basic understanding of circuit design.

Best Practices for Using Breadboards

When working with breadboards, keep the following best practices in mind:

- Use color-coded jumper wires for better organization and readability.

- Keep wires as short as possible to minimize stray capacitance and inductance.

- Avoid overloading the breadboard with too many components or high-current devices.

- Double-check your connections to prevent short circuits and ensure proper functionality.

- Use a multimeter to test continuity and troubleshoot issues.

Best Practices for Designing and Using PCBs

When designing and using PCBs, consider the following best practices:

- Use a reliable PCB design software to create your circuit layout.

- Follow proper design rules, such as maintaining appropriate trace widths and clearances.

- Consider using ground planes to reduce electromagnetic interference and improve signal integrity.

- Use appropriate solder and soldering techniques to ensure reliable connections.

- Test your PCB thoroughly before final assembly and deployment.

Frequently Asked Questions (FAQ)

-

Can I use a breadboard for a permanent project?

While it is possible to use a breadboard for a permanent project, it is not recommended. Breadboards are designed for temporary prototyping and testing, and their connections may become loose over time, leading to reliability issues. -

How do I convert my breadboard prototype to a PCB?

To convert your breadboard prototype to a PCB, you’ll need to create a schematic diagram of your circuit using a PCB design software. Then, you’ll design the PCB layout, ensuring proper component placement and routing. Finally, you’ll send your design files to a PCB fabrication service to manufacture your board. -

Can I reuse a PCB for multiple projects?

PCBs are designed for specific projects and are not easily reusable. While you may be able to salvage some components from a PCB, the board itself is generally not reusable once it has been fabricated and assembled. -

How do I choose the right components for my breadboard or PCB project?

When selecting components for your project, consider factors such as voltage and current ratings, package size, and compatibility with your circuit design. Consult datasheets and application notes for guidance, and ensure that your components are sourced from reliable suppliers. -

What safety precautions should I take when working with breadboards and PCBs?

Always follow proper safety guidelines when working with electronics. Use appropriate personal protective equipment (PPE) such as safety glasses and gloves when handling components and soldering. Ensure your work area is well-ventilated and free from flammable materials. Disconnect power sources before making any changes to your circuit, and never exceed the rated voltage or current limits of your components.

Conclusion

Choosing between a breadboard and a PCB for your electronic projects depends on various factors, including project complexity, durability, cost, and time constraints. Breadboards are ideal for quick prototyping and testing, while PCBs are better suited for complex, durable, and professional-looking projects. By understanding the advantages and disadvantages of each option and following best practices for design and assembly, you can make an informed decision and bring your electronic ideas to life.

Remember, the key to success in any electronic project is careful planning, attention to detail, and continuous learning. Whether you choose a breadboard or a PCB, always prioritize safety, quality, and functionality to ensure the best possible outcome for your projects.

No responses yet