What is a PCB Guard Ring?

A PCB (Printed Circuit Board) guard ring is a conductive trace or layer that surrounds sensitive areas of a PCB, such as high-impedance nodes or critical signal traces. The primary purpose of a guard ring is to protect these sensitive areas from electromagnetic interference (EMI), crosstalk, and leakage currents. By creating a low-impedance path around the protected area, the guard ring helps to maintain signal integrity and prevent unwanted interactions between different parts of the circuit.

Types of PCB Guard Rings

There are two main types of PCB guard rings:

-

Copper Guard Rings: These are made from copper traces or planes on the PCB. They are typically connected to a low-impedance point, such as ground or a reference voltage, to provide a stable reference for the protected area.

-

Conductive Ink Guard Rings: These are created using conductive ink or paint applied to the surface of the PCB. They offer similar protection to copper guard rings but can be applied after the PCB has been manufactured, making them a flexible option for retrofitting existing designs.

| Type | Advantages | Disadvantages |

|---|---|---|

| Copper Guard Rings | – Integrated into PCB design – Low impedance connection |

– Requires planning during PCB layout – May increase PCB complexity |

| Conductive Ink Guard Rings | – Can be applied after PCB manufacture – Flexible placement |

– Higher impedance than copper – May degrade over time |

How Do PCB Guard Rings Work?

PCB guard rings work by providing a low-impedance path around sensitive areas of the circuit. This low-impedance path helps to shunt any unwanted signals or currents away from the protected area, preventing them from interfering with the desired signal.

Electromagnetic Interference (EMI) Protection

One of the primary functions of a PCB guard ring is to protect against EMI. EMI can come from various sources, such as nearby electronic devices, power lines, or even other parts of the same circuit. By surrounding sensitive areas with a grounded or low-impedance guard ring, any incoming EMI will be absorbed or diverted away from the protected area, minimizing its impact on the desired signal.

Crosstalk Prevention

Crosstalk occurs when signals from one part of a circuit unintentionally influence signals in another part of the circuit. This can happen due to capacitive or inductive coupling between adjacent traces or components. PCB guard rings help to prevent crosstalk by providing a barrier between different parts of the circuit, reducing the likelihood of unwanted interactions.

Leakage Current Reduction

In high-impedance circuits, such as those found in analog or low-power applications, leakage currents can significantly impact signal quality and accuracy. PCB guard rings help to reduce leakage currents by providing a low-impedance path around the sensitive area, effectively shunting any leakage currents away from the protected components.

Designing PCB Guard Rings

When designing PCB guard rings, several factors must be considered to ensure optimal performance and effectiveness.

Placement and Sizing

The placement and sizing of the guard ring are critical to its effectiveness. The guard ring should be positioned as close as possible to the protected area while maintaining sufficient spacing to prevent unwanted interactions. The width of the guard ring should be chosen based on the expected frequency and magnitude of the interference, with wider traces offering better protection against low-frequency interference.

Grounding and Connection

For a PCB guard ring to be effective, it must be properly grounded or connected to a low-impedance reference point. This connection should be made using a low-impedance path, such as a wide trace or multiple vias, to ensure that any absorbed interference is quickly and efficiently shunted away from the protected area.

Material Selection

The choice of material for the guard ring can also impact its effectiveness. Copper is the most common material for PCB guard rings due to its excellent conductivity and ease of integration into the PCB design. However, in some cases, conductive ink or paint may be preferred for its flexibility and ability to be applied after PCB manufacture.

Applications of PCB Guard Rings

PCB guard rings find applications in a wide range of electronic devices and systems, particularly those that are sensitive to EMI or require high signal integrity.

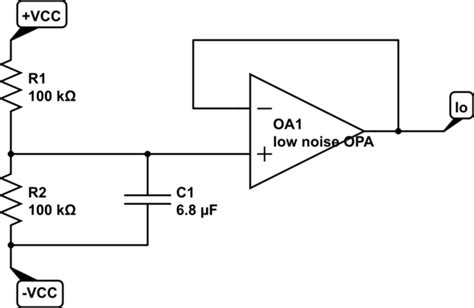

Analog and Mixed-Signal Circuits

Analog and mixed-signal circuits often deal with low-level signals that are particularly susceptible to interference and crosstalk. PCB guard rings are commonly used in these applications to protect sensitive components, such as operational amplifiers, analog-to-digital converters (ADCs), and digital-to-analog converters (DACs).

Wireless Communication Devices

Wireless communication devices, such as smartphones, tablets, and IoT devices, rely on clear and reliable signal transmission and reception. PCB guard rings are used in these devices to protect sensitive RF components, such as antennas, filters, and amplifiers, from interference and crosstalk.

Medical Electronics

Medical electronic devices, such as patient monitors, imaging systems, and diagnostic equipment, require high accuracy and reliability. PCB guard rings are used in these applications to protect sensitive analog and digital components from interference, ensuring accurate measurements and reliable operation.

Automotive Electronics

Automotive electronic systems, such as engine control units, infotainment systems, and advanced driver assistance systems (ADAS), operate in harsh environments with numerous potential sources of EMI. PCB guard rings are used in these systems to protect sensitive components and ensure reliable operation in the presence of interference.

Best Practices for Implementing PCB Guard Rings

To ensure the effectiveness of PCB guard rings, designers should follow these best practices:

-

Plan Early: Incorporate guard rings into the PCB design from the beginning, as retrofitting them later can be challenging and may compromise performance.

-

Prioritize Sensitive Areas: Focus on protecting the most sensitive areas of the circuit, such as high-impedance nodes, critical signal traces, and components with low noise tolerance.

-

Minimize Interruptions: Avoid interrupting the guard ring with gaps or crossings, as this can reduce its effectiveness. If crossings are unavoidable, use techniques such as stitching capacitors or guard traces to maintain the ring’s integrity.

-

Provide Adequate Spacing: Ensure sufficient spacing between the guard ring and the protected area to prevent unwanted interactions, while still keeping the ring close enough to be effective.

-

Use Low-Impedance Connections: Connect the guard ring to a low-impedance reference point, such as ground or a dedicated reference plane, using wide traces or multiple vias to minimize impedance.

-

Consider Frequency and Magnitude: Choose the appropriate width and spacing for the guard ring based on the expected frequency and magnitude of the interference.

-

Simulate and Test: Perform simulations and testing to validate the effectiveness of the guard ring and make any necessary adjustments to optimize performance.

Frequently Asked Questions (FAQ)

-

What is the difference between a guard ring and a shield?

A guard ring is a conductive trace or layer that surrounds sensitive areas of a PCB to protect against EMI, crosstalk, and leakage currents. A shield, on the other hand, is a physical barrier, such as a metal enclosure or conductive foam, that surrounds the entire PCB or sensitive components to protect against external EMI. -

Can guard rings be used in multi-layer PCBs?

Yes, guard rings can be used in multi-layer PCBs. In fact, multi-layer designs offer additional opportunities for implementing guard rings, such as using dedicated guard ring layers or creating guard rings on multiple layers for improved protection. -

How do I determine the optimal width and spacing for a guard ring?

The optimal width and spacing for a guard ring depend on factors such as the expected frequency and magnitude of the interference, the sensitivity of the protected components, and the available space on the PCB. Generally, wider traces and closer spacing offer better protection, but designers must balance this with other design constraints. Simulations and testing can help determine the most effective configuration for a given application. -

Are there any drawbacks to using PCB guard rings?

While PCB guard rings offer numerous benefits, they can also increase the complexity of the PCB design and may require additional space on the board. In some cases, the presence of a guard ring may also impact the performance of the protected components, such as by increasing parasitic capacitance or inductance. Careful design and testing can help mitigate these potential drawbacks. -

Can guard rings be used in conjunction with other EMI protection techniques?

Yes, guard rings can be used in combination with other EMI protection techniques, such as shielding, filtering, and proper grounding. In fact, using multiple protection methods can provide a more comprehensive defense against interference and ensure optimal signal integrity in sensitive applications.

Conclusion

PCB guard rings are a valuable tool for protecting sensitive areas of a circuit from electromagnetic interference, crosstalk, and leakage currents. By providing a low-impedance path around the protected area, guard rings help to maintain signal integrity and ensure reliable operation in a wide range of applications, from analog and mixed-signal circuits to wireless communication devices and medical electronics.

When designing PCB guard rings, careful consideration must be given to factors such as placement, sizing, grounding, and material selection to ensure optimal performance. By following best practices and incorporating guard rings into the PCB design process from the beginning, designers can effectively mitigate the impact of interference and improve the overall reliability and performance of their electronic devices and systems.

As electronic systems continue to become more complex and operate in increasingly challenging environments, the use of PCB guard rings and other EMI protection techniques will remain essential for ensuring the integrity and reliability of sensitive signals and components.

No responses yet