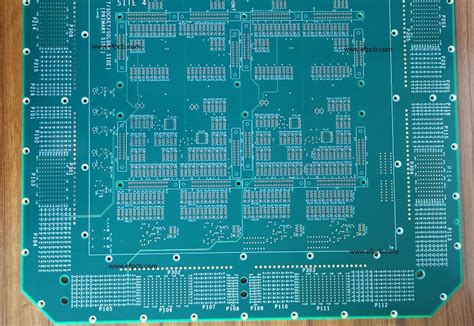

Introduction to Gold PCB

In the world of electronics, printed circuit boards (PCBs) play a crucial role in connecting and supporting electronic components. To ensure the reliability and longevity of these boards, various finishing techniques are employed, and one of the most popular methods is gold plating. Gold PCBs, also known as gold-plated PCBs, offer superior protection against corrosion, oxidation, and wear, making them an ideal choice for high-reliability applications.

What is a Gold PCB?

A gold PCB is a printed circuit board that has been coated with a thin layer of gold through either immersion or electroplating processes. The gold layer serves as a protective barrier against environmental factors and enhances the electrical conductivity of the board. Gold PCBs are widely used in industries such as aerospace, military, medical, and telecommunications, where reliability and durability are of utmost importance.

Advantages of Gold PCBs

-

Enhanced Corrosion Resistance: Gold is one of the least reactive metals, making it highly resistant to corrosion and oxidation. By applying a gold layer on the PCB surface, the board becomes protected from harsh environments and maintains its integrity over time.

-

Improved Electrical Conductivity: Gold is an excellent conductor of electricity, second only to silver. When used as a finishing material on PCBs, gold ensures efficient and reliable electrical connections between components, minimizing signal loss and improving overall performance.

-

Wear Resistance: Gold PCBs are more resistant to wear and abrasion compared to other finishes like tin or copper. This makes them suitable for applications that involve frequent insertions and removals of connectors or exposure to mechanical stress.

-

Solderability: Gold-plated PCBs offer excellent solderability, allowing for easy and reliable soldering of components. The gold layer prevents the formation of oxide layers on the surface, ensuring a strong and durable solder joint.

-

Extended Shelf Life: Gold PCBs have a longer shelf life compared to other finishes. The gold layer prevents the formation of oxide layers on the surface, which can degrade the solderability and performance of the board over time.

Gold PCB Finishing Techniques

There are two primary methods for applying a gold layer on PCBs: immersion gold and electroplated gold. Each technique has its own advantages and considerations.

Immersion Gold (ENIG)

Immersion gold, also known as Electroless Nickel Immersion Gold (ENIG), is a popular finishing technique for PCBs. In this process, the copper surface of the PCB is first coated with a thin layer of nickel through an electroless plating process. The nickel layer acts as a barrier between the copper and the subsequent gold layer, preventing the formation of intermetallic compounds that can degrade the solderability of the board.

After the nickel layer is applied, the board is immersed in a gold solution, where a thin layer of gold is deposited on top of the nickel through a displacement reaction. The typical thickness of the gold layer in ENIG is between 0.05 and 0.2 microns.

Advantages of Immersion Gold

-

Uniform Coverage: Immersion gold provides a uniform and consistent gold layer across the entire surface of the PCB, including fine features and hard-to-reach areas.

-

Cost-Effective: Compared to electroplated gold, immersion gold is a more cost-effective option due to the thinner gold layer and the simpler process involved.

-

Suitable for Fine-Pitch Components: The thin gold layer in immersion gold makes it suitable for fine-pitch components and high-density PCB designs.

Considerations for Immersion Gold

-

Limited Wear Resistance: Due to the thin gold layer, immersion gold may not provide the same level of wear resistance as electroplated gold, especially in applications with frequent insertions and removals.

-

Nickel Sensitivity: Some individuals may have allergic reactions to nickel, which is used as the barrier layer in immersion gold. In such cases, alternative finishes like electroplated gold may be preferred.

Electroplated Gold (Hard Gold)

Electroplated gold, also known as hard gold, involves the deposition of a thicker layer of gold on the PCB surface through an electroplating process. In this method, the PCB is submerged in a gold plating solution, and an electric current is applied to deposit the gold ions onto the surface. The thickness of the gold layer in electroplated gold can range from 0.5 to several microns, depending on the application requirements.

Advantages of Electroplated Gold

-

Durability: The thicker gold layer in electroplated gold provides excellent wear resistance and durability, making it suitable for applications with frequent insertions and removals or exposure to mechanical stress.

-

Customizable Thickness: The thickness of the gold layer can be customized based on the specific requirements of the application, allowing for enhanced protection and performance.

-

Nickel-Free Option: Electroplated gold can be applied directly on the copper surface without the need for a nickel barrier layer, making it a suitable choice for individuals with nickel sensitivity.

Considerations for Electroplated Gold

-

Higher Cost: Due to the thicker gold layer and the more complex process involved, electroplated gold is generally more expensive than immersion gold.

-

Potential for Uneven Coverage: Electroplated gold may not provide the same level of uniform coverage as immersion gold, especially in hard-to-reach areas or fine features.

Choosing the Right Gold PCB Finishing Technique

When selecting between immersion gold and electroplated gold for your PCB, consider the following factors:

-

Application Requirements: Evaluate the specific requirements of your application, such as wear resistance, durability, and electrical performance, to determine which finishing technique is most suitable.

-

Budget: Consider the cost implications of each technique, taking into account the initial investment, process complexity, and long-term maintenance costs.

-

PCB Design: Assess the design of your PCB, including the component density, fine features, and surface area, to ensure compatibility with the chosen finishing technique.

-

Environmental Factors: Consider the environmental conditions in which your PCB will operate, such as temperature, humidity, and exposure to corrosive substances, to select the appropriate gold finishing technique.

Table: Comparison of Immersion Gold and Electroplated Gold

| Feature | Immersion Gold (ENIG) | Electroplated Gold (Hard Gold) |

|---|---|---|

| Gold Layer Thickness | 0.05-0.2 microns | 0.5-several microns |

| Durability | Moderate | High |

| Cost | Lower | Higher |

| Uniform Coverage | Excellent | Good |

| Suitability for Fine-Pitch Components | High | Moderate |

| Nickel Sensitivity | Potential Issue | Nickel-Free Option Available |

Frequently Asked Questions (FAQ)

-

What is the difference between immersion gold and electroplated gold?

Immersion gold involves the deposition of a thin gold layer (0.05-0.2 microns) on top of a nickel barrier layer through a displacement reaction. Electroplated gold, on the other hand, involves the deposition of a thicker gold layer (0.5-several microns) directly on the copper surface through an electroplating process. -

Which gold PCB finishing technique is more durable?

Electroplated gold (hard gold) provides higher durability and wear resistance compared to immersion gold due to its thicker gold layer. It is more suitable for applications with frequent insertions and removals or exposure to mechanical stress. -

Is immersion gold suitable for fine-pitch components?

Yes, immersion gold is highly suitable for fine-pitch components and high-density PCB designs due to its thin and uniform gold layer coverage. -

Can electroplated gold be used for individuals with nickel sensitivity?

Yes, electroplated gold can be applied directly on the copper surface without the need for a nickel barrier layer, making it a suitable choice for individuals with nickel sensitivity. -

How do I choose between immersion gold and electroplated gold for my PCB?

When choosing between immersion gold and electroplated gold, consider factors such as application requirements, budget, PCB design, and environmental conditions. Evaluate the specific needs of your project and consult with PCB manufacturers or experts to determine the most suitable gold finishing technique.

Conclusion

Gold PCBs offer superior protection, reliability, and performance for critical electronic applications. Whether you choose immersion gold or electroplated gold, these finishing techniques provide enhanced corrosion resistance, improved electrical conductivity, and extended shelf life for your PCBs. By understanding the advantages and considerations of each technique and evaluating your specific project requirements, you can select the most suitable gold PCB finishing method to ensure the long-term success of your electronic devices.

No responses yet