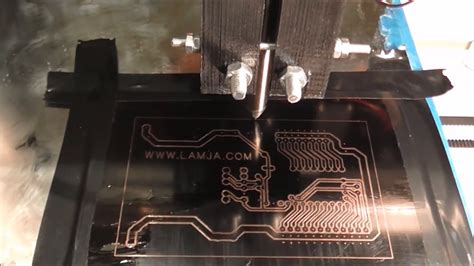

What is a PCB Printer?

A PCB printer is a specialized machine designed to print circuit patterns directly onto PCB substrates, such as FR-4 or ceramic. These printers use various technologies, including inkjet and screen printing, to deposit conductive inks or pastes onto the substrate, creating the desired circuit pattern. PCB printers offer a fast, accurate, and cost-effective alternative to traditional PCB manufacturing methods, such as etching and milling.

Benefits of Using a PCB Printer

Faster Turnaround Times

One of the primary advantages of using a PCB printer is the significantly reduced turnaround time compared to traditional manufacturing methods. PCB printers can typically produce a complete circuit board in a matter of hours, as opposed to days or weeks required for etching or milling. This rapid production capability is especially beneficial for prototyping and small-batch manufacturing, where quick iterations and time-to-market are critical.

Cost-Effectiveness

PCB printers offer a cost-effective solution for low-volume production runs. Traditional manufacturing methods often require significant setup costs and minimum order quantities, making them less economical for small batches. In contrast, PCB printers have lower setup costs and can efficiently handle small production runs, making them an ideal choice for startups, research institutions, and businesses with limited budgets.

Design Flexibility

PCB printers provide greater design flexibility compared to traditional manufacturing methods. They can easily accommodate complex circuit patterns, fine pitch components, and unconventional board shapes. This flexibility allows designers to create innovative and compact PCB layouts without the limitations imposed by etching or milling processes.

Environmentally Friendly

Traditional PCB manufacturing methods often involve the use of hazardous chemicals, such as etchants and solvents, which can have a negative impact on the environment. PCB printers, on the other hand, use eco-friendly conductive inks and produce less waste, making them a more sustainable choice for circuit board production.

Types of PCB Printers

There are two main types of PCB printers: inkjet and screen printers. Each type has its own advantages and limitations, making them suitable for different applications and production requirements.

Inkjet PCB Printers

Inkjet PCB printers use a print head with numerous nozzles to deposit conductive ink droplets onto the PCB substrate. The print head moves across the substrate, selectively depositing ink to create the desired circuit pattern. Inkjet printers offer several advantages, including:

- High resolution: Inkjet printers can achieve very fine details and narrow trace widths, making them suitable for dense and complex PCB designs.

- Quick setup: Inkjet printers require minimal setup time, as the circuit pattern is directly printed onto the substrate without the need for masks or stencils.

- Ease of use: Inkjet printers are relatively easy to operate and maintain, with user-friendly software and interfaces.

However, inkjet printers also have some limitations:

- Slower print speeds: Compared to screen printers, inkjet printers have slower print speeds, making them less suitable for high-volume production.

- Limited ink options: The selection of conductive inks compatible with inkjet printers is relatively limited compared to screen printing inks.

Screen PCB Printers

Screen PCB printers use a mesh screen with a stencil of the circuit pattern to transfer conductive ink or paste onto the PCB substrate. A squeegee is used to force the ink through the screen’s openings, depositing it onto the substrate in the desired pattern. Screen printers offer several advantages, including:

- High print speeds: Screen printers can produce PCBs much faster than inkjet printers, making them ideal for high-volume production.

- Versatile ink options: Screen printers are compatible with a wide range of conductive inks and pastes, including solder paste, allowing for greater flexibility in material selection.

- Thicker ink deposits: Screen printing allows for thicker ink deposits compared to inkjet printing, which can be beneficial for certain applications, such as creating conductive traces with lower resistance.

However, screen printers also have some limitations:

- Longer setup times: Screen printers require the creation of a stencil for each circuit pattern, which can be time-consuming and increase setup costs.

- Lower resolution: Screen printers typically have lower resolution compared to inkjet printers, making them less suitable for very fine details and dense PCB layouts.

Key Considerations When Choosing a PCB Printer

When selecting a PCB printer for your manufacturing needs, there are several key factors to consider:

Print Resolution

The print resolution of a PCB printer determines the minimum feature size and trace width it can produce. Higher resolution printers can accommodate denser PCB layouts and finer details. Consider your design requirements and choose a printer with a resolution that meets or exceeds your needs.

Print Speed

Print speed is an important consideration, especially for high-volume production. Screen printers generally offer faster print speeds compared to inkjet printers. Evaluate your production volume and turnaround time requirements to select a printer with an appropriate print speed.

Ink Compatibility

Different PCB printers are compatible with different types of conductive inks and pastes. Consider the materials you plan to use and ensure that the printer you choose is compatible with those inks. Additionally, evaluate the availability and cost of the inks to ensure a reliable supply chain and cost-effectiveness.

Substrate Compatibility

PCB printers may have specific requirements for substrate materials, thicknesses, and sizes. Verify that the printer you choose is compatible with the substrates you intend to use, such as FR-4, ceramic, or flexible materials.

Software and Connectivity

Consider the software and connectivity options offered by the PCB printer. Look for user-friendly interfaces, compatibility with popular PCB design software, and the ability to import standard file formats, such as Gerber or ODB++. Additionally, evaluate the printer’s connectivity options, such as USB, Ethernet, or Wi-Fi, to ensure seamless integration with your existing workflow.

Cost and Maintenance

PCB printers vary in cost, depending on their features, capabilities, and brand. Evaluate your budget and the long-term cost of ownership, including consumables, maintenance, and repairs. Consider the printer’s reliability, warranty, and the availability of local support and service to minimize downtime and ensure a smooth operation.

FAQs

1. Can PCB printers handle multi-layer boards?

Some advanced PCB printers can handle multi-layer boards by printing conductive layers and insulating layers separately and then laminating them together. However, the capabilities and processes may vary depending on the specific printer model and manufacturer.

2. What is the typical resolution of a PCB printer?

The resolution of PCB printers can vary depending on the technology used. Inkjet printers can typically achieve resolutions of up to 1200 dpi, while screen printers may have resolutions around 100-200 dpi. However, the actual achievable resolution may also depend on factors such as the ink type and substrate properties.

3. How long does it take to print a PCB using a printer?

The print time for a PCB depends on several factors, including the printer type, print speed, circuit complexity, and board size. Inkjet printers may take several minutes to an hour to print a single board, while screen printers can produce multiple boards per minute. However, these are rough estimates, and actual print times can vary significantly.

4. Are PCB printers suitable for high-volume production?

Screen PCB printers are generally more suitable for high-volume production due to their faster print speeds and ability to handle larger substrates. Inkjet printers are typically better suited for prototyping, small-batch production, and applications requiring high-resolution prints.

5. What is the cost of a typical PCB printer?

The cost of a PCB printer can range from a few thousand dollars for entry-level inkjet printers to tens or even hundreds of thousands of dollars for high-end, industrial-grade screen printers. The actual cost will depend on the printer’s features, capabilities, and brand. It’s essential to consider your specific requirements and budget when selecting a PCB printer.

Conclusion

PCB printers offer a fast, flexible, and cost-effective solution for circuit board manufacturing, particularly for prototyping and small-batch production. By understanding the different types of PCB printers, their benefits, and the key considerations when choosing a printer, you can make an informed decision that meets your specific needs and requirements. As technology continues to advance, PCB printers are poised to play an increasingly important role in the world of electronic device manufacturing, enabling faster innovation, shorter time-to-market, and more sustainable production practices.

| Inkjet PCB Printers | Screen PCB Printers | |

|---|---|---|

| Print Resolution | High (up to 1200 dpi) | Lower (100-200 dpi) |

| Print Speed | Slower | Faster |

| Ink Compatibility | Limited | Versatile |

| Setup Time | Quick | Longer |

| Ideal Application | Prototyping, small-batch, high-resolution | High-volume, thicker ink deposits |

As you embark on your journey to select the perfect PCB printer for your manufacturing needs, keep in mind the unique advantages and limitations of each printer type, and prioritize the factors that are most critical to your success. With the right PCB printer in your arsenal, you’ll be well-equipped to tackle the challenges of modern circuit board manufacturing and bring your electronic innovations to life.

No responses yet