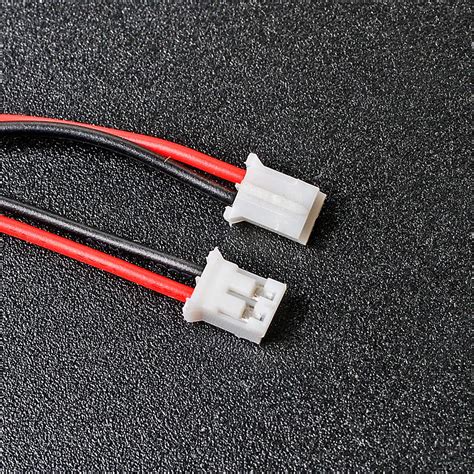

What are JST Connectors?

JST connectors are electrical connectors manufactured by JST, a Japanese company founded in 1957. These connectors are designed for wire-to-wire and wire-to-board connections in electronic devices, offering a wide range of sizes, shapes, and configurations to suit various applications. JST connectors are known for their reliability, durability, and ease of use, making them a popular choice among electronics manufacturers and hobbyists alike.

Common Features of JST Connectors

Despite the diverse range of JST connector types, they share some common features that make them attractive for electronic applications:

- Compact size: JST connectors are generally smaller than other types of connectors, allowing for space-saving designs in electronic devices.

- Reliable connection: JST connectors provide a secure and stable connection, ensuring reliable power and signal transmission.

- Easy assembly: Most JST connectors are designed for easy assembly, with simple crimp or solder terminations and clear polarity indicators.

- Versatility: JST offers a wide range of connector types, sizes, and configurations, making them suitable for various applications and industries.

Types of JST Connectors

JST manufactures a wide variety of connector types, each designed for specific applications and requirements. Some of the most common JST connector types include:

1. JST XH Connectors

JST XH connectors are one of the most popular types of JST connectors, widely used in hobby electronics, RC vehicles, and battery packs. They are rated for a current of 3A and a voltage of 250V, making them suitable for low-power applications.

Features:

– 2.5mm pitch

– Crimp or solder termination

– Locking mechanism for secure connection

– Available in 2 to 16 pins

Applications:

– Battery packs

– RC vehicles

– Hobby electronics

2. JST PH Connectors

JST PH connectors are smaller than XH connectors, with a pitch of 2.0mm. They are commonly used in smaller electronic devices, such as mobile phones, cameras, and portable audio devices.

Features:

– 2.0mm pitch

– Crimp termination

– Locking mechanism for secure connection

– Available in 2 to 16 pins

Applications:

– Mobile phones

– Cameras

– Portable audio devices

3. JST SM Connectors

JST SM connectors are surface-mount connectors designed for wire-to-board connections. They are commonly used in automotive electronics, industrial control systems, and consumer electronics.

Features:

– 2.5mm or 3.96mm pitch

– Surface-mount termination

– Locking mechanism for secure connection

– Available in 2 to 16 pins

Applications:

– Automotive electronics

– Industrial control systems

– Consumer electronics

4. JST VH Connectors

JST VH connectors are high-current connectors designed for power supply applications. They are rated for a current of up to 10A and a voltage of 250V, making them suitable for high-power applications.

Features:

– 3.96mm pitch

– Crimp termination

– Locking mechanism for secure connection

– Available in 2 to 8 pins

Applications:

– Power supplies

– Battery packs

– Industrial equipment

5. JST ZH Connectors

JST ZH connectors are low-profile connectors designed for space-constrained applications. They have a pitch of 1.5mm and are commonly used in compact electronic devices, such as wearables and medical devices.

Features:

– 1.5mm pitch

– Crimp termination

– Locking mechanism for secure connection

– Available in 2 to 6 pins

Applications:

– Wearable devices

– Medical devices

– Compact electronic devices

6. JST GH Connectors

JST GH connectors are high-density connectors designed for applications that require a large number of pins in a small space. They have a pitch of 1.25mm and are commonly used in consumer electronics, such as smartphones and tablets.

Features:

– 1.25mm pitch

– Crimp termination

– Locking mechanism for secure connection

– Available in 4 to 16 pins

Applications:

– Smartphones

– Tablets

– Compact electronic devices

Choosing the Right JST Connector

When selecting a JST connector for your application, consider the following factors:

- Current and voltage rating: Ensure that the connector’s rating meets or exceeds your application’s power requirements.

- Pitch: Choose a connector with a pitch that suits your space constraints and PCB design.

- Number of pins: Select a connector with the appropriate number of pins for your application’s signal and power requirements.

- Termination method: Consider whether crimp or solder termination is more suitable for your manufacturing process.

- Environmental factors: Take into account the operating environment, such as temperature, humidity, and vibration, and choose a connector with appropriate ratings and materials.

JST Connector Comparison Table

| Connector Type | Pitch (mm) | Current Rating (A) | Voltage Rating (V) | Number of Pins | Termination Method | Common Applications |

|---|---|---|---|---|---|---|

| JST XH | 2.5 | 3 | 250 | 2-16 | Crimp or Solder | Hobby electronics, RC vehicles, battery packs |

| JST PH | 2.0 | 2 | 250 | 2-16 | Crimp | Mobile phones, cameras, portable audio devices |

| JST SM | 2.5 or 3.96 | 3 or 5 | 250 | 2-16 | Surface-mount | Automotive electronics, industrial control systems, consumer electronics |

| JST VH | 3.96 | 10 | 250 | 2-8 | Crimp | Power supplies, battery packs, industrial equipment |

| JST ZH | 1.5 | 1.5 | 50 | 2-6 | Crimp | Wearable devices, medical devices, compact electronic devices |

| JST GH | 1.25 | 0.5 | 50 | 4-16 | Crimp | Smartphones, tablets, compact electronic devices |

Frequently Asked Questions (FAQ)

-

Q: Are JST connectors waterproof?

A: Most JST connectors are not inherently waterproof. However, some series, such as the JST WP (Waterproof) connectors, are designed for use in environments exposed to moisture or water. -

Q: Can I mix and match different JST connector types?

A: Generally, it is not recommended to mix and match different JST connector types, as they may have different pitches, locking mechanisms, and electrical ratings. Always use the same connector type for mating connectors. -

Q: How do I crimp JST connectors?

A: Crimping JST connectors requires the use of a specific crimp tool designed for the connector series. Each JST connector series has its own crimp tool, which ensures a proper and secure connection. Follow the manufacturer’s instructions for the crimping process. -

Q: Can I solder JST connectors instead of crimping them?

A: While most JST connectors are designed for crimp termination, some series, such as the JST XH connectors, can be soldered. However, soldering may not provide the same level of reliability and mechanical strength as crimping. -

Q: Are JST connectors polarized?

A: Yes, most JST connectors are polarized to ensure proper orientation and prevent incorrect mating. Polarization is typically achieved through the use of a key or a shape difference in the connector housing.

Conclusion

JST connectors offer a reliable, compact, and cost-effective solution for wire-to-wire and wire-to-board connections in various electronic applications. With a wide range of connector types, sizes, and configurations, JST connectors can be found in numerous industries, from consumer electronics to automotive and industrial applications. When selecting a JST connector for your project, consider factors such as current and voltage ratings, pitch, number of pins, termination method, and environmental requirements to ensure optimal performance and reliability.

No responses yet