Introduction to SMT Assembly

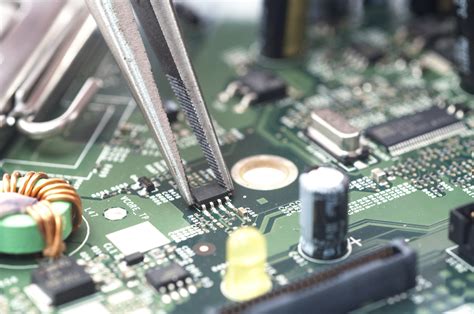

Surface-mount technology (SMT) assembly is a crucial process in the manufacturing of modern electronic devices. SMT involves placing and soldering electronic components onto the surface of a printed circuit board (PCB). This technique has revolutionized the electronics industry, enabling the production of smaller, lighter, and more efficient devices.

Choosing the right SMT assembly partner is critical to the success of your product. In this article, we will discuss why you should consider working with us for your SMT assembly needs.

Key Benefits of SMT Assembly

| Benefit | Description |

|---|---|

| Miniaturization | SMT allows for smaller components and denser PCB layouts |

| Efficiency | Automated assembly processes enable high-volume production |

| Reliability | Precise component placement and soldering improves product reliability |

| Cost-effectiveness | Automation and standardization reduce manufacturing costs |

Our SMT Assembly Capabilities

State-of-the-Art Equipment

We invest in the latest SMT assembly equipment to ensure the highest quality standards. Our production lines feature:

- High-speed pick-and-place machines

- Automated optical inspection (AOI) systems

- Reflow soldering ovens with precise temperature control

- X-ray inspection for hidden solder joints

Equipment Specifications

| Equipment | Specifications |

|---|---|

| Pick-and-Place Machine | – Placement speed: 100,000 CPH – Placement accuracy: ±25 μm |

| AOI System | – Camera resolution: 10 μm – Inspection speed: 60 cm²/s |

| Reflow Oven | – Temperature range: 80-350°C – Heating zones: 8 |

| X-ray Inspection | – Resolution: 0.1 μm – Magnification: up to 2000x |

Skilled Technicians

Our team of skilled technicians has extensive experience in SMT assembly. They undergo regular training to stay up-to-date with the latest industry trends and best practices. This ensures that your products are assembled with the utmost precision and care.

Quality Control

We adhere to strict quality control measures throughout the SMT assembly process. Our quality assurance team conducts rigorous inspections at various stages of production, including:

- Incoming material inspection

- First article inspection (FAI)

- In-process quality checks

- Final functional testing

Inspection Methods

| Inspection Method | Description |

|---|---|

| Visual Inspection | Manual inspection of components and solder joints |

| AOI | Automated inspection of component placement and solder joints |

| X-ray Inspection | Non-destructive inspection of hidden solder joints |

| Functional Testing | Testing of the assembled PCB’s functionality |

By implementing these quality control measures, we ensure that your products meet the highest standards of reliability and performance.

Our SMT Assembly Process

PCB Design Review

Before starting the SMT assembly process, our team reviews your PCB design files. We check for any potential issues that could affect manufacturability, such as:

- Component footprint accuracy

- Solder mask clearance

- Copper trace width and spacing

- Drill hole sizes

We provide feedback and recommendations to optimize your design for SMT assembly.

Component Sourcing

We offer component sourcing services to streamline your supply chain. Our extensive network of suppliers allows us to procure high-quality components at competitive prices. We also ensure that all components are RoHS compliant and meet your specifications.

Prototyping

We understand the importance of prototyping in the product development process. Our rapid prototyping services allow you to test and validate your designs before moving into full-scale production. We offer:

- Quick-turn PCB fabrication

- Low-volume SMT assembly

- Functional testing and debugging

Volume Production

Once your design is finalized, we transition to volume production. Our efficient SMT assembly lines can handle a wide range of production volumes, from small batches to large-scale runs. We work closely with you to establish a production schedule that meets your time-to-market goals.

Our Commitment to Customer Service

Dedicated Project Management

When you work with us, you are assigned a dedicated project manager who serves as your single point of contact. Your project manager oversees your SMT assembly project from start to finish, ensuring that:

- Your project stays on schedule

- You are kept informed of progress

- Any issues are promptly addressed

Flexible Engagement Models

We offer flexible engagement models to suit your specific needs. Whether you require turnkey SMT assembly services or consignment-based manufacturing, we can tailor our services to your requirements.

Competitive Pricing

We strive to offer competitive pricing without compromising on quality. Our efficient processes and economies of scale enable us to provide cost-effective SMT assembly services. We also offer volume discounts for larger production runs.

Case Studies

Case Study 1: Wireless IoT Device

A leading IoT Solutions provider approached us to manufacture their latest wireless sensor device. The challenges included:

- Miniaturized PCB design with high component density

- Strict RF performance requirements

- Accelerated time-to-market

Our SMT assembly team worked closely with the client’s engineers to optimize the PCB design for manufacturability. We utilized our advanced pick-and-place equipment to accurately place the miniature components. Through our rigorous quality control processes, we ensured that each device met the required RF performance standards.

The result was a successful product launch, with the client achieving their time-to-market goals and receiving positive feedback from end-users.

Case Study 2: Automotive Electronics Module

An automotive electronics manufacturer needed a reliable SMT assembly partner for their critical safety module. The key requirements were:

- Compliance with automotive quality standards (e.g., IATF 16949)

- Robust traceability and documentation

- High-volume production capacity

Our team implemented a comprehensive quality management system to meet the stringent automotive standards. We utilized automated traceability systems to track each component and assembly throughout the production process. Our high-volume SMT assembly lines enabled us to meet the client’s production targets consistently.

The client appreciated our attention to detail and commitment to quality. Our SMT assembly services helped them maintain their reputation for delivering reliable automotive electronics.

Frequently Asked Questions (FAQ)

1. What is your minimum order quantity (MOQ) for SMT assembly?

Our MOQ for SMT assembly varies depending on the complexity of the PCB and the components involved. However, we strive to be as flexible as possible and can accommodate small batch sizes. Please contact us with your specific requirements, and we’ll work with you to find a solution.

2. How long does the SMT assembly process typically take?

The lead time for SMT assembly depends on factors such as the complexity of the PCB, the availability of components, and the production volume. On average, our lead times range from 2-4 weeks for standard projects. However, we also offer expedited services for time-critical projects.

3. Do you offer PCB design services?

Yes, we have a team of experienced PCB designers who can assist you with your PCB design. We offer PCB layout, schematic capture, and design for manufacturing (DFM) services. Our designers work closely with our SMT assembly team to ensure that your PCB is optimized for manufacturability.

4. What certifications do you hold for SMT assembly?

We hold several industry-recognized certifications, including:

– ISO 9001 for quality management

– ISO 14001 for environmental management

– IATF 16949 for automotive quality management

– IPC-A-610 for acceptability of electronic assemblies

These certifications demonstrate our commitment to quality, reliability, and continuous improvement.

5. How do you handle intellectual property (IP) protection?

We understand the importance of protecting your intellectual property. We have strict confidentiality agreements in place with all our employees and suppliers. We also implement secure data management systems to safeguard your sensitive information. When you work with us, you can trust that your IP is in safe hands.

Conclusion

Choosing the right SMT assembly partner is essential for the success of your electronic products. With our state-of-the-art equipment, skilled technicians, and robust quality control processes, we are well-equipped to handle your SMT assembly needs.

Our commitment to customer service, flexible engagement models, and competitive pricing set us apart from other SMT assembly providers. We work closely with you to understand your unique requirements and deliver solutions that meet your quality, timeline, and budget goals.

Don’t just take our word for it – our case studies demonstrate our ability to tackle complex SMT assembly projects and deliver results. From miniaturized IoT devices to critical automotive electronics, we have the expertise to bring your products to life.

Contact us today to discuss your SMT assembly requirements. Let us be your partner in turning your electronic product ideas into reality.

No responses yet