Prototyping and Design Support

One of the key services offered by electronics manufacturers is prototyping and design support. This involves collaborating with your team to refine your product design, identify potential issues, and create functional prototypes for testing and validation. EMS providers have the expertise and tools to:

- Review and optimize your schematic and PCB layout

- Suggest component selections based on availability, cost, and performance

- Create 3D models and renderings of your product

- Fabricate prototype PCBs and assemble them with components

- Conduct initial testing and debugging of prototypes

By leveraging the knowledge and resources of an EMS partner during the design phase, you can save time and money by catching and addressing issues early on, before moving into full-scale production.

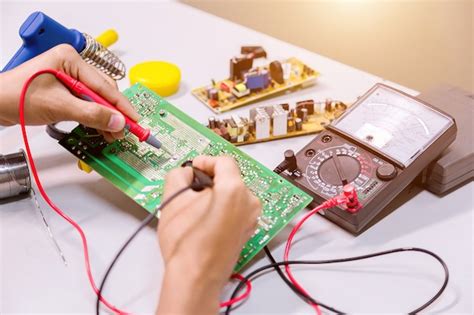

PCB Assembly

PCB assembly is a core service provided by electronics manufacturers. This process involves populating printed circuit boards with electronic components according to your design specifications. EMS providers typically offer two main types of PCB assembly:

- Surface Mount Technology (SMT) Assembly

- Components are placed directly onto the surface of the PCB

- Suitable for high-volume production and smaller components

-

Automated pick-and-place machines are used for precision and speed

-

Through-Hole Technology (THT) Assembly

- Components with wire leads are inserted through holes in the PCB

- Often used for larger components or those requiring more mechanical stability

- Can be done manually or with automated insertion equipment

An experienced EMS provider will have the capability to handle both SMT and THT assembly, as well as mixed-technology boards that incorporate both techniques. They will also have strict quality control measures in place, such as automated optical inspection (AOI) and X-ray inspection, to ensure the accuracy and reliability of the assembled PCBs.

Box Build and System Integration

Beyond PCB assembly, many electronics manufacturers offer box build and system integration services. This involves taking the assembled PCBs and incorporating them into a complete product, including:

- Enclosure fabrication and customization

- Cable and wiring harness assembly

- Integration of sub-assemblies, such as displays, sensors, and connectors

- Final product assembly and packaging

By entrusting your EMS partner with box build and system integration, you can benefit from their experience in designing for manufacturability, sourcing compatible components, and optimizing the assembly process. This can lead to a more efficient production process, reduced costs, and a higher-quality final product.

Supply Chain Management

Effective supply chain management is essential for ensuring the timely delivery of your electronic products. Electronics manufacturers often have established relationships with component suppliers and can leverage their buying power to secure better pricing and availability. They can also:

- Monitor component lifecycles and suggest alternatives for obsolete parts

- Manage inventory levels to minimize excess stock while ensuring adequate supply

- Implement just-in-time (JIT) delivery to reduce storage costs and improve cash flow

- Handle import/export logistics and comply with international regulations

By outsourcing supply chain management to your EMS provider, you can focus on your core competencies while relying on their expertise to keep your production running smoothly.

Testing and Quality Control

To ensure that your electronic products meet the highest standards of quality and reliability, electronics manufacturers offer comprehensive testing and quality control services. These may include:

- In-circuit testing (ICT) to verify the functionality of individual components and circuits

- Functional testing to validate the overall performance of the assembled product

- Environmental testing, such as temperature cycling and vibration testing, to assess durability

- Burn-in testing to identify early failures and improve long-term reliability

- Final quality inspection and packaging validation

An EMS provider with a robust quality management system, such as one certified to ISO 9001 standards, will have documented procedures and traceability measures in place to ensure consistent quality throughout the production process.

Reverse Logistics and After-Sales Support

Finally, electronics manufacturers can provide valuable support even after your products have been delivered to customers. Reverse logistics services, such as:

- Warranty repairs and replacements

- Refurbishment and remanufacturing of returned products

- Recycling and disposal of end-of-life products

These services can help you manage customer satisfaction, reduce waste, and comply with environmental regulations. Some EMS providers may also offer after-sales support, such as technical assistance and spare parts management, to help you maintain a strong relationship with your customers.

| Service | Benefits |

|---|---|

| Prototyping and Design Support | Catch and address issues early, optimize design for manufacturability |

| PCB Assembly | Precise and reliable assembly of PCBs using SMT and THT techniques |

| Box Build and System Integration | Complete product assembly, reduced costs, improved efficiency |

| Supply Chain Management | Secure component availability, manage inventory, handle logistics |

| Testing and Quality Control | Ensure product quality and reliability, comply with standards |

| Reverse Logistics and After-Sales | Manage customer satisfaction, reduce waste, comply with regulations, provide ongoing support |

Frequently Asked Questions

-

What is the difference between an electronics manufacturer and an Electronics Manufacturing Services provider?

An electronics manufacturer typically designs and produces its own brand of electronic products, while an electronics manufacturing services (EMS) provider offers manufacturing and related services to other companies that design and sell electronic products. -

How do I choose the right electronics manufacturing partner for my project?

When selecting an EMS partner, consider factors such as their experience in your industry, the range of services they offer, their quality management system, their financial stability, and their ability to scale production to meet your needs. -

What are the advantages of outsourcing electronics manufacturing?

Outsourcing to an EMS provider can offer several benefits, including access to specialized expertise and equipment, reduced capital investment, improved supply chain management, increased flexibility and scalability, and the ability to focus on your core competencies. -

How can an electronics manufacturer help with supply chain management?

An EMS provider can leverage their relationships with component suppliers to secure better pricing and availability, monitor component lifecycles, manage inventory levels, implement just-in-time delivery, and handle import/export logistics. -

What types of testing and quality control services do electronics manufacturers typically offer?

Electronics manufacturers often provide a range of testing and quality control services, such as in-circuit testing, functional testing, environmental testing, burn-in testing, and final quality inspection, to ensure the quality and reliability of the products they produce.

By partnering with an experienced electronics manufacturing services provider, you can access a comprehensive range of services that will help bring your electronic product to market efficiently, cost-effectively, and with the highest standards of quality. From prototyping and design support to PCB assembly, box build, and after-sales services, an EMS partner can provide the expertise and resources you need to succeed in today’s competitive electronics industry.

No responses yet