Key Components of the New Product Introduction Process

The NPI process typically consists of several key components, each of which plays a vital role in the successful launch of a new product:

1. Ideation and Concept Development

The first stage of the NPI process involves generating ideas for new products and developing them into viable concepts. This stage includes:

- Market research to identify customer needs and opportunities

- Brainstorming sessions to generate ideas

- Concept development and refinement

- Feasibility studies to assess technical and financial viability

2. Product Design and Development

Once a concept has been selected, the next stage is to design and develop the product. This stage includes:

- Detailed product design and specification

- Prototyping and testing

- Design for manufacturability (DFM) to ensure the product can be produced efficiently

- Sourcing of materials and components

- Compliance with regulatory requirements and industry standards

3. Process Design and Validation

In parallel with product design and development, the manufacturing process must also be designed and validated. This stage includes:

- Process mapping and optimization

- Equipment selection and procurement

- Process validation and quality assurance

- Establishment of production metrics and key performance indicators (KPIs)

4. Supply Chain Management

Effective supply chain management is critical to the success of the NPI process. This stage includes:

- Supplier selection and qualification

- Negotiation of contracts and pricing

- Logistics and inventory management

- Risk assessment and mitigation strategies

5. Pilot Production and Ramp-Up

Before full-scale production begins, pilot runs are conducted to validate the manufacturing process and identify any issues. This stage includes:

- Pilot production runs

- Process refinement and optimization

- Training of production staff

- Ramp-up to full production volume

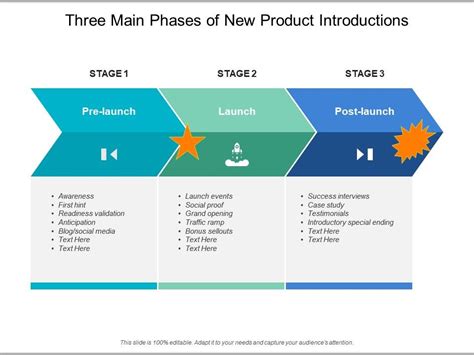

6. Launch and Post-Launch Support

The final stage of the NPI process involves launching the product to the market and providing post-launch support. This stage includes:

- Product launch and marketing activities

- Customer support and feedback mechanisms

- Continuous improvement and product lifecycle management

Benefits of a Robust New Product Introduction Process

Implementing a well-structured and efficient NPI process offers several benefits to companies:

-

Faster time-to-market: A streamlined NPI process enables companies to bring new products to market more quickly, gaining a competitive advantage.

-

Reduced costs: By identifying and resolving issues early in the process, companies can avoid costly rework and delays.

-

Improved product quality: A rigorous NPI process ensures that products meet customer requirements and quality standards, reducing the risk of defects and returns.

-

Enhanced customer satisfaction: By delivering high-quality products that meet customer needs, companies can improve customer satisfaction and loyalty.

-

Increased profitability: An efficient NPI process helps companies to optimize production costs and maximize product margins.

Challenges in New Product Introduction

Despite the benefits, the NPI process also presents several challenges that companies must overcome:

-

Managing complexity: With increasing product complexity and shorter product lifecycles, managing the NPI process can be challenging.

-

Coordination across functions: The NPI process requires close collaboration between multiple functions, including engineering, manufacturing, supply chain, and marketing.

-

Balancing innovation and risk: Companies must balance the need for innovation with the risks associated with new product development, such as technical challenges and market uncertainties.

-

Resource constraints: The NPI process can be resource-intensive, requiring significant investments in time, money, and personnel.

-

Regulatory compliance: Ensuring compliance with regulatory requirements and industry standards can be a complex and time-consuming process.

Best Practices for Successful New Product Introduction

To overcome these challenges and ensure a successful NPI process, companies should adopt the following best practices:

-

Establish a cross-functional NPI team: Create a dedicated, cross-functional team responsible for managing the NPI process from start to finish.

-

Define clear roles and responsibilities: Clearly define the roles and responsibilities of each team member to ensure accountability and avoid duplication of efforts.

-

Implement a stage-gate process: Use a stage-gate process to break down the NPI process into discrete stages, with clear milestones and decision points.

-

Leverage project management tools: Utilize project management tools and techniques, such as Gantt charts and critical path analysis, to plan and track progress.

-

Engage suppliers early: Involve suppliers early in the process to ensure timely delivery of materials and components and to leverage their expertise.

-

Conduct thorough testing and validation: Invest in comprehensive testing and validation activities to identify and resolve issues early in the process.

-

Foster a culture of continuous improvement: Encourage a culture of continuous improvement, using lessons learned from each NPI project to refine and optimize the process.

The Role of Technology in New Product Introduction

Technology plays an increasingly important role in the NPI process, enabling companies to streamline and automate various activities. Some key technologies include:

-

Product Lifecycle Management (PLM) software: PLM software provides a centralized platform for managing product data, from concept to retirement.

-

Computer-Aided Design (CAD) and Engineering (CAE) tools: CAD and CAE tools enable designers and engineers to create and test virtual prototypes, reducing the need for physical prototypes.

-

Manufacturing Execution Systems (MES): MES software helps companies to manage and optimize production processes, ensuring consistent quality and efficiency.

-

Supply Chain Management (SCM) software: SCM software enables companies to manage and coordinate their supply chain activities, from supplier selection to logistics and inventory management.

-

Internet of Things (IoT) and Industry 4.0: IoT and Industry 4.0 technologies, such as connected sensors and advanced analytics, enable companies to collect and analyze real-time data from the production process, enabling predictive maintenance and process optimization.

Measuring the Success of New Product Introduction

To assess the effectiveness of their NPI process, companies should establish key performance indicators (KPIs) and track them regularly. Some common KPIs for NPI include:

-

Time-to-market: The time taken from concept to product launch.

-

Development cost: The total cost of developing and launching the new product.

-

Product quality: The number of defects or returns per unit sold.

-

Customer satisfaction: The level of customer satisfaction with the new product, as measured through surveys or feedback.

-

Sales and profitability: The sales volume and profitability of the new product over time.

By tracking these KPIs and continuously refining their NPI process based on the results, companies can ensure that they are delivering high-quality, innovative products to the market in a timely and cost-effective manner.

The Future of New Product Introduction

As markets continue to evolve and customer demands become more complex, the NPI process will also need to adapt. Some key trends shaping the future of NPI include:

-

Increased focus on sustainability: With growing concerns about environmental impact, companies will need to incorporate sustainability considerations into their NPI process, from material selection to end-of-life management.

-

Adoption of agile methodologies: Agile development methodologies, which emphasize rapid iteration and customer feedback, will become increasingly important in the NPI process, enabling companies to respond more quickly to changing market needs.

-

Integration of artificial intelligence (AI) and machine learning (ML): AI and ML technologies will play a growing role in the NPI process, enabling companies to analyze vast amounts of data and make more informed decisions about product design, production, and supply chain management.

-

Collaboration with external partners: Companies will increasingly collaborate with external partners, such as suppliers, customers, and research institutions, to access new technologies, expertise, and market insights.

-

Emphasis on mass customization: With the rise of personalized products and services, companies will need to adapt their NPI process to enable mass customization, balancing the benefits of standardization with the need for customization.

Frequently Asked Questions (FAQ)

-

What is the difference between New Product Development (NPD) and New Product Introduction (NPI)?

New Product Development (NPD) refers to the entire process of creating a new product, from idea generation to commercialization. New Product Introduction (NPI), on the other hand, focuses specifically on the later stages of the NPD process, including design, manufacturing, and launch. -

How long does the NPI process typically take?

The duration of the NPI process can vary widely depending on the complexity of the product, the industry, and the company’s resources and capabilities. On average, the process can take anywhere from several months to several years. -

What are the most common reasons for NPI failures?

Some common reasons for NPI failures include inadequate market research, poor product design, manufacturing issues, supply chain disruptions, and lack of cross-functional collaboration. -

How can companies ensure alignment between the NPI process and their overall business strategy?

To ensure alignment, companies should establish clear objectives and priorities for their NPI process, based on their overall business strategy. They should also involve senior management in key decisions and regularly review progress against strategic goals. -

What are some emerging technologies that can support the NPI process?

Some emerging technologies that can support the NPI process include 3D printing for rapid prototyping, virtual and augmented reality for product design and testing, blockchain for supply chain transparency and traceability, and big data analytics for demand forecasting and process optimization.

Conclusion

New Product Introduction is a critical process for companies looking to remain competitive and grow their business in today’s fast-paced, ever-changing market landscape. By implementing a well-structured, efficient NPI process, companies can bring new products to market faster, reduce costs, improve product quality, enhance customer satisfaction, and increase profitability.

To succeed in NPI, companies must overcome various challenges, such as managing complexity, coordinating across functions, balancing innovation and risk, and ensuring regulatory compliance. They can do so by adopting best practices, such as establishing cross-functional teams, implementing stage-gate processes, leveraging technology, and fostering a culture of continuous improvement.

As the future of NPI continues to evolve, companies will need to adapt to emerging trends, such as increased focus on sustainability, adoption of agile methodologies, integration of AI and ML, collaboration with external partners, and emphasis on mass customization.

By staying attuned to these trends and continuously refining their NPI process, companies can position themselves for success in an increasingly competitive and dynamic market environment.

No responses yet