Introduction to PCB Manufacturing

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They are used in everything from smartphones and computers to medical devices and aerospace equipment. PCB manufacturing is a complex process that requires precision, expertise, and advanced technology. In this article, we will compare PCB manufacturing in China and the United States, two of the world’s largest producers of PCBs.

What is PCB Manufacturing?

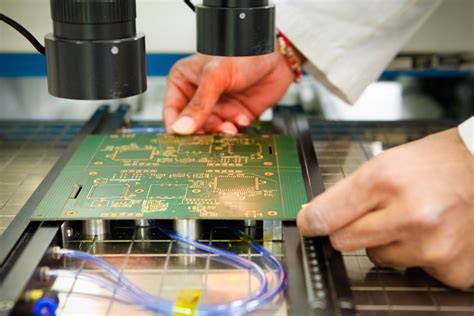

PCB manufacturing is the process of creating a printed circuit board, which is a flat board made of insulating material with conductive pathways etched onto it. The board is used to mechanically support and electrically connect electronic components using conductive tracks, pads, and other features.

The PCB manufacturing process typically involves the following steps:

- Design: The PCB design is created using specialized software, such as Altium Designer or Eagle.

- Fabrication: The PCB is fabricated using a series of chemical and mechanical processes, including etching, drilling, and plating.

- Assembly: The electronic components are placed on the PCB and soldered into place.

- Testing: The assembled PCB is tested to ensure that it functions as intended.

PCB Manufacturing in China

China is the world’s largest producer of PCBs, accounting for over 50% of global production. The country has a well-established supply chain, a skilled workforce, and advanced manufacturing facilities.

Advantages of PCB Manufacturing in China

- Lower Costs: Labor and material costs are significantly lower in China compared to the United States, which allows Chinese manufacturers to offer competitive prices.

- Large Production Capacity: China has a vast network of PCB manufacturers, ranging from small, specialized shops to large, high-volume factories. This allows for greater flexibility in terms of production volume and lead times.

- Experienced Workforce: China has a large pool of skilled workers with experience in PCB manufacturing, which ensures high-quality production.

- Access to Raw Materials: China has a well-established supply chain for raw materials used in PCB manufacturing, such as copper, fiberglass, and epoxy resin.

Disadvantages of PCB Manufacturing in China

- Intellectual Property Concerns: There have been instances of intellectual property theft and counterfeiting in China, which can be a concern for companies looking to protect their designs.

- Language Barriers: Communication can be a challenge when working with Chinese manufacturers, as English proficiency may be limited.

- Longer Lead Times: Shipping times from China to the United States can be lengthy, which can impact project timelines.

- Quality Control: While many Chinese manufacturers adhere to strict quality control standards, there have been instances of substandard products being shipped from China.

PCB Manufacturing in the United States

The United States is the second-largest producer of PCBs, with a well-established industry that has been in operation for decades.

Advantages of PCB Manufacturing in the United States

- Quality Control: American manufacturers are known for their strict quality control standards, which ensure high-quality products.

- Intellectual Property Protection: The United States has strong intellectual property laws that protect companies from theft and counterfeiting.

- Proximity to Customers: For American companies, working with a domestic PCB manufacturer can simplify logistics and reduce lead times.

- Advanced Technology: American PCB manufacturers have access to the latest technologies and equipment, which allows for the production of complex, high-density PCBs.

Disadvantages of PCB Manufacturing in the United States

- Higher Costs: Labor and material costs are significantly higher in the United States compared to China, which can result in higher prices for customers.

- Limited Production Capacity: While the United States has a well-established PCB industry, production capacity is limited compared to China.

- Aging Workforce: Many skilled PCB manufacturing workers in the United States are approaching retirement age, which could lead to a shortage of experienced labor in the future.

Comparison of PCB Manufacturing in China and the United States

| Factor | China | United States |

|---|---|---|

| Cost | Lower | Higher |

| Quality | Variable | High |

| Lead Times | Longer | Shorter |

| Production Capacity | High | Lower |

| Intellectual Property Protection | Concerns | Strong |

| Technology | Advanced | Advanced |

Which Country is Better for PCB Manufacturing?

The answer to this question depends on the specific needs of the company or project. For companies that prioritize low costs and high production volume, China may be the better choice. For companies that prioritize quality, intellectual property protection, and shorter lead times, the United States may be the better option.

Ultimately, the decision to manufacture PCBs in China or the United States should be based on a careful analysis of the project requirements, budget, and timeline.

Frequently Asked Questions (FAQ)

1. What is the typical lead time for PCB manufacturing in China?

Lead times for PCB manufacturing in China can vary depending on the complexity of the design and the production volume. Typical lead times range from 2-4 weeks, but can be longer for larger or more complex orders.

2. Are there any tariffs or import duties on PCBs manufactured in China?

Yes, there are tariffs and import duties on PCBs manufactured in China and shipped to the United States. The exact amount depends on the specific product classification and can change based on ongoing trade negotiations between the two countries.

3. What certifications do American PCB manufacturers typically hold?

American PCB manufacturers may hold a variety of certifications, including ISO 9001 (quality management), UL (safety), and IPC (industry standards). It is important to verify the specific certifications held by a manufacturer before placing an order.

4. Can I visit a PCB manufacturer in China before placing an order?

Yes, many Chinese PCB manufacturers welcome visits from potential customers. Visiting a facility in person can provide valuable insight into the manufacturing process, quality control procedures, and communication styles of the company.

5. What is the minimum order quantity for PCB manufacturing in the United States?

Minimum order quantities for PCB manufacturing in the United States can vary depending on the manufacturer and the specific product. Some manufacturers may have no minimum order quantity, while others may require a minimum of 100 or more pieces.

Conclusion

PCB manufacturing is a critical industry that plays a vital role in the production of modern electronics. China and the United States are two of the world’s largest producers of PCBs, each with its own strengths and weaknesses.

For companies looking to manufacture PCBs, the decision between China and the United States should be based on a careful analysis of project requirements, budget, and timeline. By understanding the advantages and disadvantages of each country, companies can make informed decisions that ensure the success of their projects.

No responses yet