Introduction to PCB Development

Printed Circuit Boards (PCBs) have revolutionized the electronics industry since their inception in the early 20th century. PCBs are the backbone of modern electronic devices, providing a platform for mounting and interconnecting electronic components. The development of PCB technology has undergone significant changes over the years, driven by the increasing demand for smaller, faster, and more complex electronic devices. In this article, we will explore the development history and trends of PCB, from its early beginnings to the latest advancements in the field.

Early History of PCB Development

The Invention of PCBs

The concept of PCBs can be traced back to the early 1900s when German inventor Albert Hanson filed a patent for a “printed wire” in 1903. However, it wasn’t until the 1930s that the first practical PCBs were developed. In 1936, Austrian engineer Paul Eisler invented the first printed circuit board as part of a radio set.

The Rise of PCBs in the 1940s and 1950s

During World War II, the demand for reliable and compact electronic equipment for military applications drove the development of PCBs. The United States National Bureau of Standards (NBS) developed a process for printing electrical circuits on a ceramic substrate, which was used in proximity fuses for anti-aircraft shells.

In the 1950s, the introduction of the Auto-Sembly process by the U.S. Army Signal Corps further advanced PCB manufacturing. This process involved the use of a copper foil laminated onto a non-conductive substrate, which was then etched to create the desired circuit pattern.

Advancements in PCB Technology

The Introduction of Through-Hole Technology

In the 1960s, through-hole technology became the dominant PCB manufacturing method. This technology involved drilling holes through the PCB and inserting electronic components with wire leads, which were then soldered onto the board. Through-hole technology allowed for the production of more complex circuits and the use of larger components.

The Shift to Surface Mount Technology (SMT)

The 1980s saw a significant shift towards Surface Mount Technology (SMT) in PCB manufacturing. SMT involves placing electronic components directly onto the surface of the PCB, without the need for drilled holes. This technology allowed for the production of smaller, more densely packed PCBs, which were essential for the development of portable electronic devices.

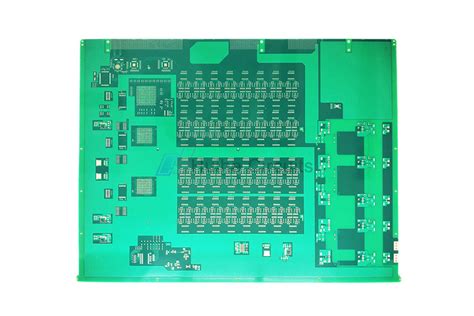

The Rise of Multilayer PCBs

As electronic devices became more complex, the need for higher density PCBs grew. Multilayer PCBs, which consist of multiple layers of conductive material separated by insulating layers, emerged as a solution. Multilayer PCBs allowed for the routing of more complex circuits and the incorporation of power and ground planes, which improved signal integrity and reduced electromagnetic interference.

Recent Trends in PCB Development

High-Speed PCB Design

With the increasing demand for faster data transmission rates, high-speed PCB design has become a critical aspect of modern electronics. High-speed PCBs are designed to minimize signal distortion and ensure signal integrity at high frequencies. This is achieved through the use of advanced materials, such as low-loss dielectrics and high-performance laminates, as well as specialized design techniques, such as controlled impedance routing and differential pair routing.

Flexible and Rigid-Flex PCBs

Flexible PCBs, made from flexible plastic substrates, have gained popularity in recent years due to their ability to conform to different shapes and reduce the overall size of electronic devices. Rigid-Flex PCBs, which combine the benefits of both rigid and flexible PCBs, have also emerged as a popular choice for applications that require both stability and flexibility, such as wearable devices and aerospace electronics.

Embedded Components and 3D PCBs

Embedded components, such as resistors, capacitors, and inductors, are components that are embedded within the layers of a PCB, rather than being mounted on the surface. This technology allows for further miniaturization and improved performance, as the embedded components are closer to the active components and have shorter signal paths.

3D PCBs, also known as three-dimensional PCBs, are a recent development in PCB technology. These PCBs feature multiple layers of circuitry that are interconnected using vertical conductive structures, such as vias and plated through-holes. 3D PCBs offer increased circuit density and improved signal integrity compared to traditional 2D PCBs.

Eco-Friendly PCB Materials and Processes

As environmental concerns continue to grow, the electronics industry has been focusing on developing eco-friendly PCB materials and processes. Some of the recent advancements in this area include:

-

Halogen-free PCB Laminates: Traditional PCB laminates often contain halogenated flame retardants, which can release harmful substances when disposed of. Halogen-free laminates use alternative flame retardants that are less harmful to the environment.

-

Lead-free soldering: The use of lead-based solders has been phased out in many countries due to the harmful effects of lead on human health and the environment. Lead-free solders, such as tin-silver-copper (SAC) alloys, have become the standard in PCB assembly.

-

Green PCB manufacturing processes: PCB manufacturers are adopting greener manufacturing processes, such as using water-based cleaning agents instead of harmful chemicals, and implementing waste reduction and recycling programs.

Future of PCB Development

Increased Adoption of IoT and Wearable Devices

The Internet of Things (IoT) and wearable devices are expected to drive the growth of the PCB industry in the coming years. As more devices become connected and wearable technology becomes more prevalent, the demand for smaller, more flexible, and high-performance PCBs will continue to increase.

Advancements in Materials Science

New materials, such as graphene and carbon nanotubes, are being explored for their potential applications in PCB technology. These materials offer unique properties, such as high conductivity, strength, and thermal stability, which could lead to the development of more advanced and efficient PCBs.

Artificial Intelligence and Machine Learning in PCB Design

Artificial Intelligence (AI) and Machine Learning (ML) are expected to play a significant role in the future of PCB design. AI and ML algorithms can be used to optimize PCB layouts, predict potential design issues, and automate the design process, leading to faster and more efficient PCB development.

Conclusion

The development of PCB technology has come a long way since its early beginnings in the early 20th century. From the first practical PCBs developed in the 1930s to the latest advancements in high-speed design, flexible and rigid-flex PCBs, and embedded components, PCB technology has continuously evolved to meet the increasing demands of the electronics industry.

As we look towards the future, the adoption of IoT and wearable devices, advancements in materials science, and the integration of AI and ML in PCB design are expected to drive further innovation in the field. With these developments, PCBs will continue to play a crucial role in shaping the future of electronics and enabling the creation of more advanced, efficient, and sustainable electronic devices.

FAQs

1. What is a Printed Circuit Board (PCB)?

A Printed Circuit Board (PCB) is a platform used to mechanically support and electrically connect electronic components using conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate.

2. What are the main differences between through-hole and surface mount technology (SMT) in PCB manufacturing?

Through-hole technology involves inserting electronic components with wire leads into drilled holes in the PCB, which are then soldered onto the board. SMT, on the other hand, involves placing components directly onto the surface of the PCB without the need for drilled holes. SMT allows for smaller, more densely packed PCBs compared to through-hole technology.

3. What are the benefits of using multilayer PCBs?

Multilayer PCBs offer several benefits, including:

– Increased circuit density: More complex circuits can be routed in a smaller space.

– Improved signal integrity: Power and ground planes can be incorporated to reduce electromagnetic interference.

– Reduced size and weight: Multilayer PCBs allow for more compact and lightweight electronic devices.

4. What are some of the eco-friendly materials and processes used in modern PCB manufacturing?

Some eco-friendly materials and processes used in PCB manufacturing include:

– Halogen-free PCB laminates, which use alternative flame retardants that are less harmful to the environment.

– Lead-free solders, such as tin-silver-copper (SAC) alloys, which have replaced lead-based solders.

– Green PCB manufacturing processes, such as using water-based cleaning agents and implementing waste reduction and recycling programs.

5. How are AI and Machine Learning expected to impact PCB design in the future?

AI and Machine Learning are expected to play a significant role in the future of PCB design by:

– Optimizing PCB layouts

– Predicting potential design issues

– Automating the design process

These advancements are expected to lead to faster and more efficient PCB development.

| PCB Development Milestones | Year |

|---|---|

| First “printed wire” patent | 1903 |

| First practical PCBs developed | 1930s |

| Auto-Sembly process introduced | 1950s |

| Through-hole technology becomes dominant | 1960s |

| Surface Mount Technology (SMT) gains popularity | 1980s |

| Multilayer PCBs emerge | 1980s |

| High-speed PCB design becomes critical | 2000s |

| Flexible and Rigid-Flex PCBs gain popularity | 2000s |

| Embedded components and 3D PCBs develop | 2010s |

| Eco-friendly PCB materials and processes adopted | 2010s |

No responses yet