Introduction

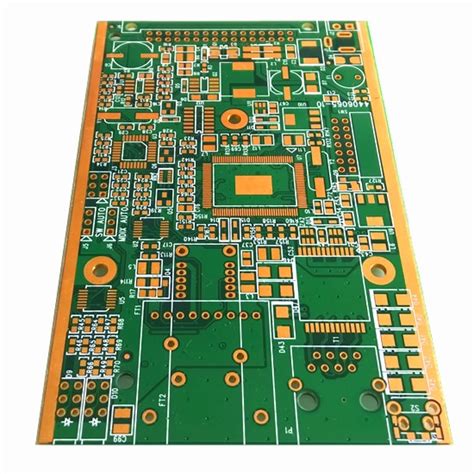

China has become a global hub for PCB manufacturing due to its competitive advantages. In this article, we will explore the 19 key advantages that make China PCB manufacturers stand out in the global market. From cost-effectiveness to advanced technology and skilled workforce, we will delve into the reasons why choosing a China PCB manufacturer can benefit your business.

Cost-Effectiveness

One of the primary advantages of working with a China PCB manufacturer is cost-effectiveness. China’s lower labor costs, coupled with its well-developed supply chain and infrastructure, enable manufacturers to offer competitive pricing without compromising on quality.

Lower Labor Costs

China’s lower labor costs are a significant factor in its cost-effectiveness. The country’s large population and relatively lower wages allow manufacturers to maintain a skilled workforce at a lower cost compared to other countries.

Well-Developed Supply Chain

China’s well-developed supply chain is another key factor in its cost-effectiveness. The country has a vast network of suppliers and manufacturers, which enables PCB manufacturers to source components and materials at competitive prices.

Infrastructure

China’s well-developed infrastructure, including transportation networks and logistics facilities, further contributes to cost-effectiveness. This infrastructure allows manufacturers to efficiently transport goods and materials, reducing lead times and costs.

Advanced Technology

China PCB manufacturers have invested heavily in advanced technology to stay competitive in the global market. From state-of-the-art equipment to innovative manufacturing processes, China’s PCB industry is at the forefront of technological advancements.

State-of-the-Art Equipment

China PCB manufacturers use state-of-the-art equipment to ensure high-quality production. This includes advanced SMT (Surface Mount Technology) machines, automated optical inspection (AOI) systems, and high-precision drilling and routing equipment.

Innovative Manufacturing Processes

China PCB manufacturers are constantly innovating their manufacturing processes to improve efficiency and quality. This includes implementing lean manufacturing principles, adopting automation technologies, and utilizing data analytics to optimize production.

Skilled Workforce

China’s PCB industry benefits from a highly skilled workforce. The country has invested heavily in education and training programs to develop a pool of talented engineers, technicians, and operators.

Technical Expertise

China’s PCB workforce possesses a high level of technical expertise. Many workers have undergone extensive training and have years of experience in the industry, enabling them to handle complex PCB designs and manufacturing processes.

Quality Control

China PCB manufacturers place a strong emphasis on quality control. Skilled quality control personnel ensure that products meet strict quality standards and specifications, reducing the risk of defects and failures.

Rapid Prototyping

China PCB manufacturers offer rapid prototyping services, allowing customers to quickly iterate and test their designs. This is particularly valuable for businesses that need to bring products to market quickly or those that require frequent design changes.

Quick Turnaround Times

China PCB manufacturers can provide quick turnaround times for prototypes, often within a matter of days. This is made possible by their efficient manufacturing processes and well-developed supply chain.

Flexibility

China PCB manufacturers are highly flexible when it comes to prototyping. They can accommodate a wide range of design requirements and can quickly adapt to changes in specifications or quantities.

Scalability

China PCB manufacturers have the capacity to scale production to meet the needs of businesses of all sizes. Whether you require small batches or large-scale production, China PCB manufacturers can accommodate your needs.

High-Volume Production

China PCB manufacturers are well-equipped to handle high-volume production. Their advanced manufacturing facilities and skilled workforce enable them to efficiently produce large quantities of PCBs while maintaining consistent quality.

Customization

China PCB manufacturers offer a high degree of customization. They can work with customers to develop custom PCB designs and specifications, ensuring that the final product meets the unique needs of each business.

Certifications and Standards

China PCB manufacturers adhere to a range of international certifications and standards, ensuring that their products meet the highest quality and safety requirements.

ISO Certifications

Many China PCB manufacturers hold ISO certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications demonstrate a commitment to quality and sustainability.

UL and RoHS Compliance

China PCB manufacturers also comply with international safety and environmental standards, such as UL (Underwriters Laboratories) and RoHS (Restriction of Hazardous Substances). This ensures that their products are safe and environmentally friendly.

Comprehensive Services

China PCB manufacturers offer a comprehensive range of services, from design and prototyping to assembly and testing. This one-stop-shop approach streamlines the manufacturing process and reduces lead times.

Design Support

Many China PCB manufacturers provide design support services, helping customers optimize their PCB designs for manufacturability and performance. This can include design reviews, DFM (Design for Manufacturability) analysis, and recommendations for materials and components.

Assembly and Testing

China PCB manufacturers offer assembly and testing services, ensuring that the final product is fully functional and meets quality standards. This can include SMT assembly, through-hole assembly, and various testing methods such as in-circuit testing (ICT) and functional testing.

Industry Experience

China PCB manufacturers have extensive experience serving a wide range of industries, from consumer electronics to automotive and aerospace. This industry experience allows them to understand the unique requirements and challenges of each sector and provide tailored solutions.

Consumer Electronics

China PCB manufacturers have a strong track record in the consumer electronics industry, producing PCBs for smartphones, tablets, wearables, and other devices. They are well-versed in the latest technologies and trends in this fast-paced industry.

Automotive and Aerospace

China PCB manufacturers also serve the automotive and aerospace industries, which have stringent requirements for quality and reliability. They have experience producing PCBs that can withstand harsh environments and meet strict safety standards.

Intellectual Property Protection

China PCB manufacturers understand the importance of protecting intellectual property (IP). Many manufacturers have implemented strict security measures to safeguard customer designs and confidential information.

Non-Disclosure Agreements

China PCB manufacturers often sign non-disclosure agreements (NDAs) with customers to protect sensitive information. These agreements legally bind the manufacturer to keep customer designs and data confidential.

Secure Facilities

China PCB manufacturers also invest in secure facilities to protect customer IP. This can include access control systems, surveillance cameras, and secure storage areas for sensitive materials and documents.

Global Reach

China PCB manufacturers have a global reach, serving customers around the world. Their extensive logistics networks and partnerships with international shipping companies enable them to efficiently deliver products to customers in various countries.

Logistics Networks

China PCB manufacturers have well-developed logistics networks, allowing them to quickly and efficiently ship products to customers worldwide. They work with reputable shipping companies to ensure that products arrive safely and on time.

Customs Expertise

China PCB manufacturers also have expertise in navigating international customs regulations. They can provide guidance on documentation, tariffs, and other import/export requirements, ensuring smooth delivery of products to customers.

Customer Support

China PCB manufacturers place a strong emphasis on customer support. They strive to build long-term relationships with customers by providing excellent service and communication throughout the manufacturing process.

Dedicated Account Managers

Many China PCB manufacturers assign dedicated account managers to each customer. These account managers serve as a single point of contact, providing updates on production status, addressing concerns, and ensuring that customer needs are met.

Language Support

China PCB manufacturers often have multilingual staff to support customers from different countries. This can include English, Japanese, German, and other languages, facilitating effective communication and understanding of customer requirements.

Continuous Improvement

China PCB manufacturers are committed to continuous improvement. They constantly seek ways to optimize their processes, improve quality, and enhance customer satisfaction.

Lean Manufacturing

Many China PCB manufacturers have adopted lean manufacturing principles to streamline their operations and reduce waste. This includes implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) and Kaizen (continuous improvement) practices.

Investment in Research and Development

China PCB manufacturers also invest in research and development (R&D) to stay at the forefront of technological advancements. They collaborate with universities, research institutions, and industry partners to develop new materials, processes, and technologies that can improve PCB performance and reliability.

Competitive Landscape

China’s PCB industry is highly competitive, with numerous manufacturers vying for market share. This competition drives innovation, quality improvement, and customer service excellence.

Market Segmentation

China PCB manufacturers serve various market segments, from low-cost, high-volume production to high-end, specialized applications. This market segmentation allows customers to find manufacturers that best suit their specific needs and requirements.

Industry Consolidation

The China PCB industry has undergone consolidation in recent years, with larger manufacturers acquiring smaller ones to expand their capabilities and market reach. This consolidation has led to the emergence of several key players that offer a comprehensive range of PCB manufacturing services.

Environmental Responsibility

China PCB manufacturers are increasingly focusing on environmental responsibility. They are adopting eco-friendly practices and materials to minimize their environmental impact and meet the growing demand for sustainable products.

Green Materials

Many China PCB manufacturers are using green materials, such as halogen-free laminates and lead-free solders, to reduce the use of hazardous substances in their products. This not only benefits the environment but also ensures compliance with international regulations such as RoHS.

Waste Management

China PCB manufacturers are implementing effective waste management practices to reduce, reuse, and recycle waste generated during the manufacturing process. This includes proper handling and disposal of chemicals, wastewater treatment, and recycling of materials such as copper and precious metals.

Future Outlook

The future outlook for China PCB manufacturers is promising. With the continued growth of the electronics industry and the increasing demand for advanced PCBs, China PCB manufacturers are well-positioned to capture new opportunities and expand their market share.

Industry 4.0

China PCB manufacturers are embracing Industry 4.0 technologies, such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, to further optimize their operations and improve product quality. These technologies enable real-time monitoring, predictive maintenance, and data-driven decision-making.

5G and Beyond

The rollout of 5G networks and the development of advanced applications such as autonomous vehicles and smart cities present new opportunities for China PCB manufacturers. They are well-equipped to produce the high-frequency, high-density PCBs required for these advanced technologies.

Conclusion

China PCB manufacturers offer a compelling value proposition for businesses seeking high-quality, cost-effective PCB solutions. With their advanced technology, skilled workforce, comprehensive services, and global reach, China PCB manufacturers are well-positioned to meet the evolving needs of the electronics industry.

By partnering with a reputable China PCB manufacturer, businesses can benefit from competitive pricing, rapid prototyping, scalable production, and a commitment to quality and customer service. As the industry continues to evolve, China PCB manufacturers are poised to play a crucial role in driving innovation and shaping the future of electronics manufacturing.

FAQ

-

Q: How do I choose the right China PCB manufacturer for my business?

A: When selecting a China PCB manufacturer, consider factors such as their experience, certifications, manufacturing capabilities, quality control processes, and customer support. Look for manufacturers that specialize in your industry and have a proven track record of delivering high-quality products. -

Q: What is the typical lead time for PCB production in China?

A: Lead times for PCB production in China can vary depending on the complexity of the design, the quantity ordered, and the manufacturer’s capacity. Typically, lead times range from 1-2 weeks for prototypes to 4-6 weeks for larger production runs. However, some manufacturers may offer expedited services for urgent orders. -

Q: How can I ensure the quality of PCBs produced by a China manufacturer?

A: To ensure the quality of PCBs produced by a China manufacturer, look for manufacturers with ISO certifications and robust quality control processes. Request samples or prototypes to evaluate the quality firsthand, and consider conducting on-site audits or inspections to verify the manufacturer’s capabilities and compliance with your requirements. -

Q: Are China PCB manufacturers able to handle complex PCB designs?

A: Yes, many China PCB manufacturers are capable of handling complex PCB designs, including high-density interconnect (HDI), multilayer, and flexible PCBs. However, it is essential to choose a manufacturer with the appropriate technology, equipment, and expertise to handle your specific design requirements. -

Q: How can I protect my intellectual property when working with a China PCB manufacturer?

A: To protect your intellectual property, consider signing a non-disclosure agreement (NDA) with the manufacturer before sharing sensitive information. Look for manufacturers with secure facilities and strict confidentiality policies. Additionally, consider filing for patents or trademarks in China to further safeguard your IP.

Advantages of China PCB Manufacturers

| Advantage | Description |

|---|---|

| Cost-Effectiveness | Lower labor costs, well-developed supply chain, and infrastructure enable competitive pricing |

| Advanced Technology | State-of-the-art equipment and innovative manufacturing processes |

| Skilled Workforce | Highly trained engineers, technicians, and operators with technical expertise |

| Rapid Prototyping | Quick turnaround times and flexibility for prototyping and design iterations |

| Scalability | Capacity to handle high-volume production and accommodate customization |

| Certifications and Standards | Adherence to international certifications (ISO) and standards (UL, RoHS) |

| Comprehensive Services | One-stop-shop approach, from design support to assembly and testing |

| Industry Experience | Extensive experience serving various industries, including consumer electronics and automotive |

| Intellectual Property Protection | Strict security measures, non-disclosure agreements, and secure facilities |

| Global Reach | Well-developed logistics networks and customs expertise for worldwide delivery |

| Customer Support | Dedicated account managers, multilingual staff, and emphasis on long-term relationships |

| Continuous Improvement | Adoption of lean manufacturing principles and investment in research and development |

| Competitive Landscape | Highly competitive industry driving innovation, quality, and customer service |

| Environmental Responsibility | Eco-friendly practices, green materials, and effective waste management |

| Future Outlook | Promising growth opportunities driven by Industry 4.0, 5G, and advanced applications |

No responses yet